Position accuracy measuring device and method for manipulator arm

A robotic arm, precision measurement technology, applied in measuring devices, manipulators, program-controlled manipulators, etc., can solve the problems of low accuracy of robotic arms and high price of laser trackers, and achieve good practicability, low cost, and easy development. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

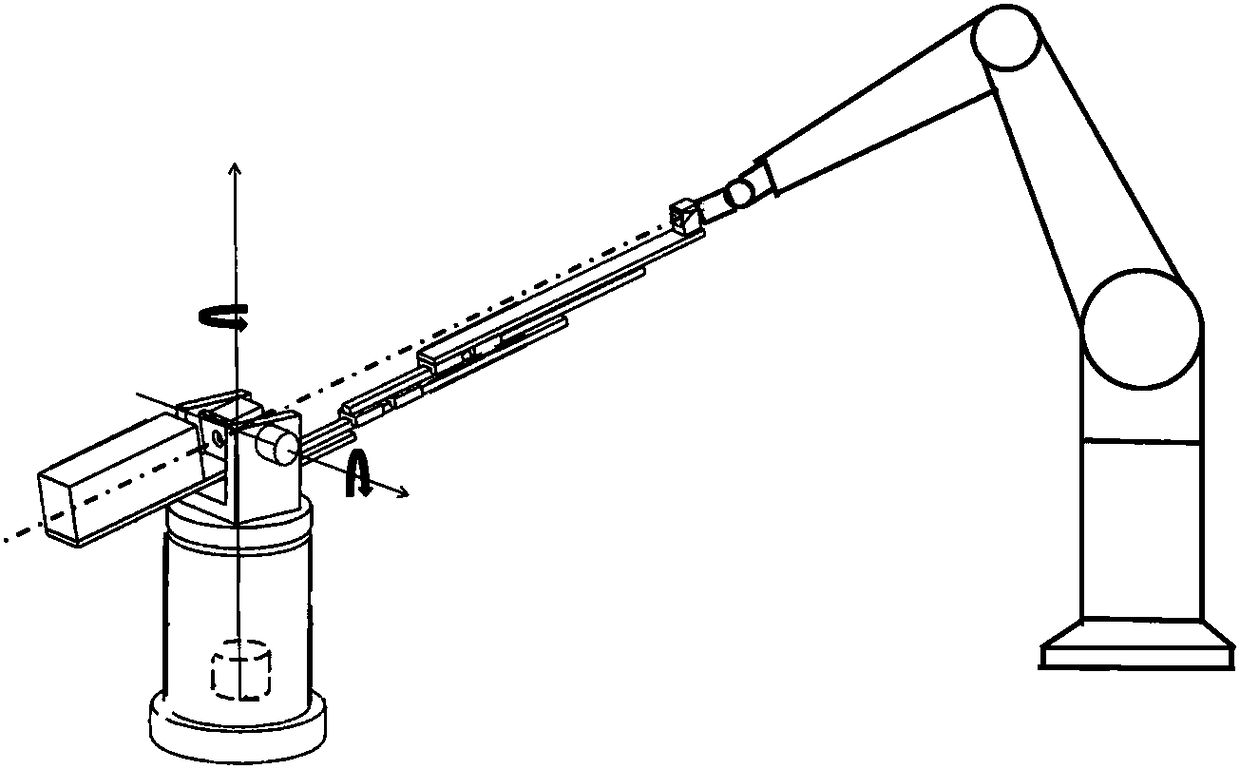

[0016] The main structure of the innovative "passive three-dimensional spherical coordinate mechanism" is as follows: (1) two turntables orthogonal to each other, including an azimuth turntable and a pitch turntable, each turntable is equipped with an angle encoder to read the actual angle; (2) Radial telescopic mechanism, which consists of two slide rails and a traction plate that pass through the rotation centers of the two turntables and are perpendicular to the pitch angle rotation axis, and the actual length of the telescopic mechanism is read by a laser interferometer fixed on the other side of the turntable center . The movement of each structure is described in detail below:

[0017] Such as figure 1 As shown, the azimuth turntable 13 is placed on the ground, and the coordinate system (X, Y, Z) of the three-dimensional spherical coordinate mechanism is provided. The rotating shaft 11 rotates 360° around the Z axis, and the azimuth θ is provided by the azimuth encoder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com