Fixing structure for magnetic steel of rotor of disk-type motor

A fixed structure, disc motor technology, applied in the magnetic circuit shape/style/structure, manufacturing of motor generators, manufacturing of stator/rotor bodies, etc. Heat dissipation and shedding prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

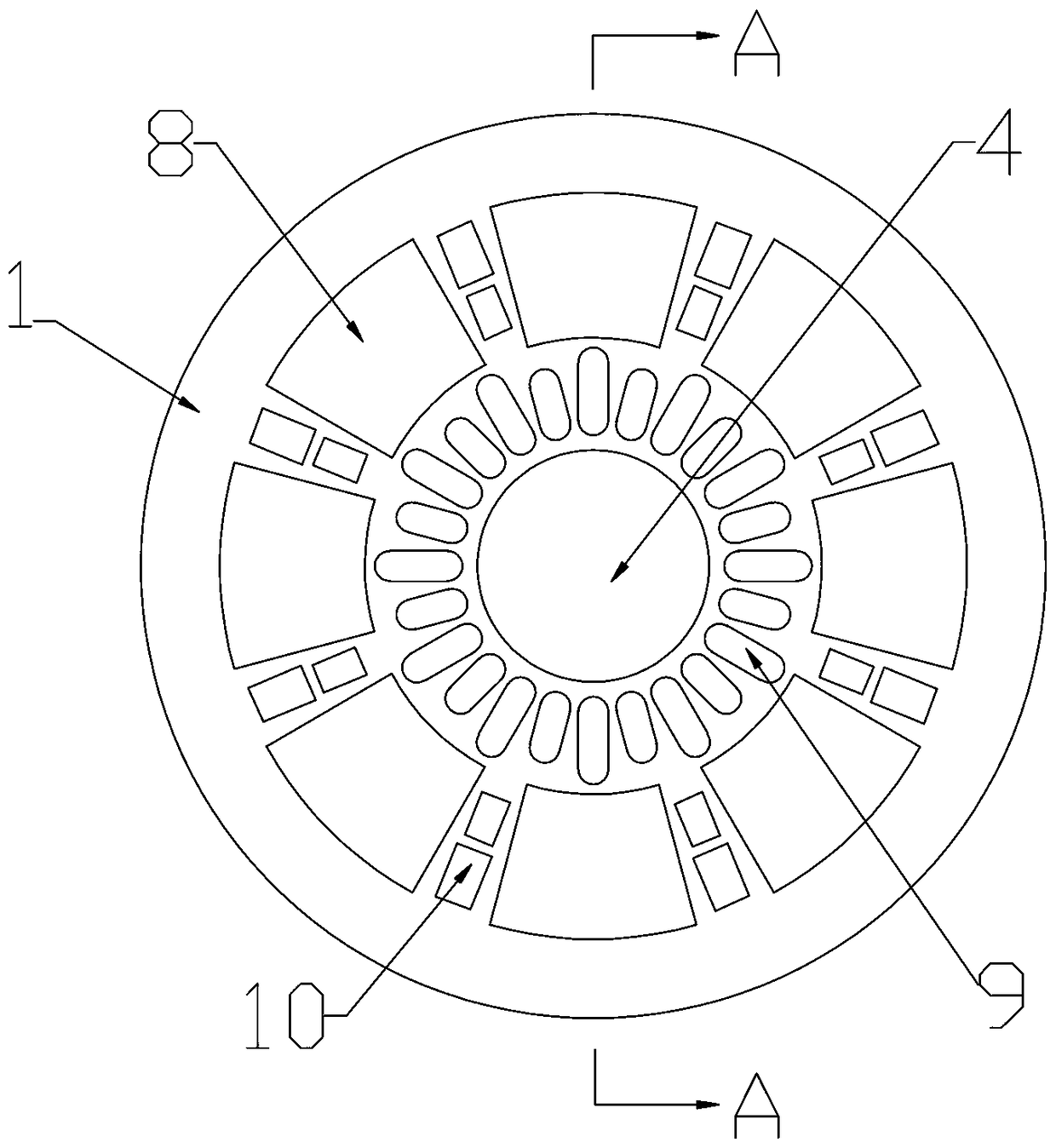

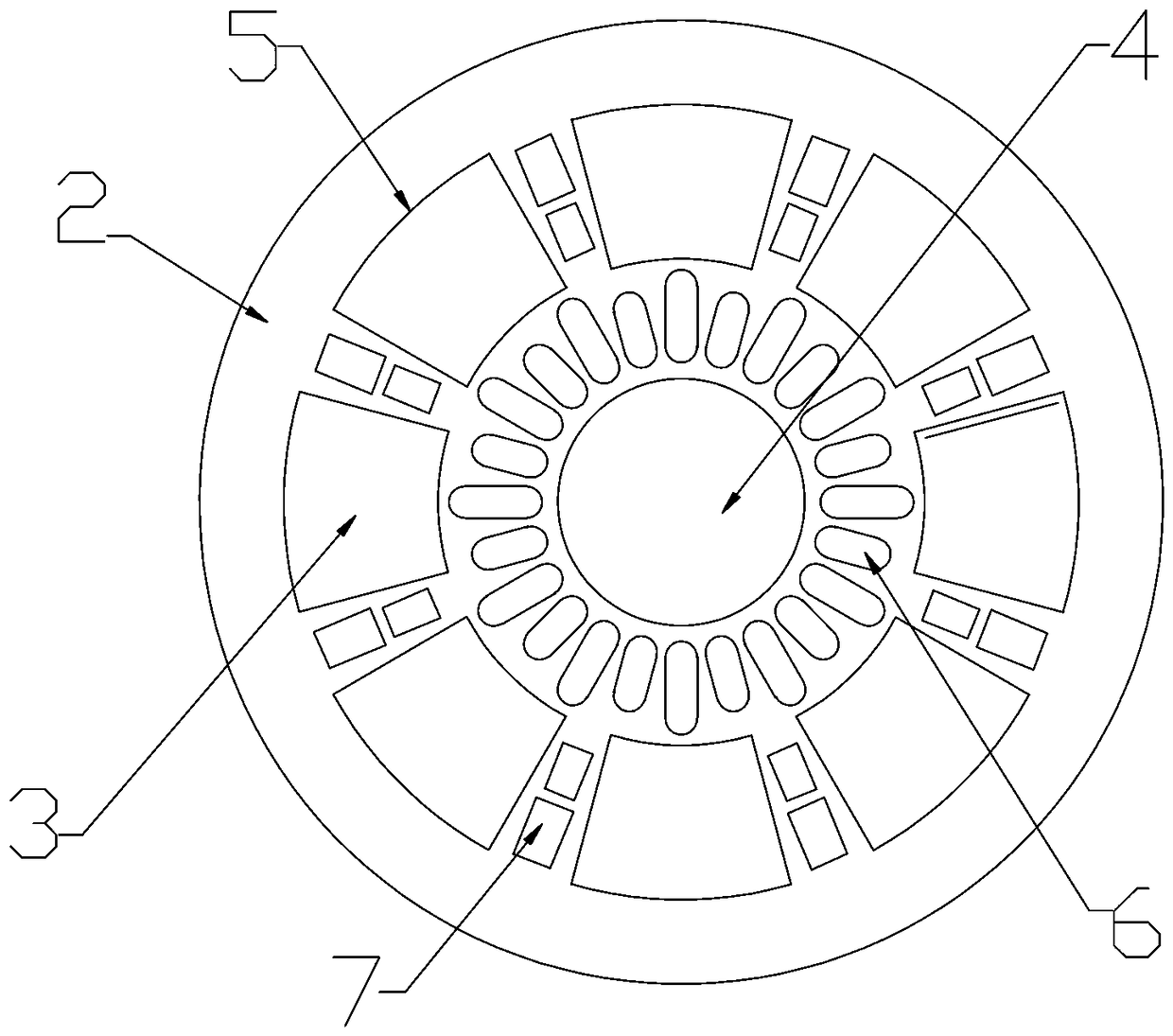

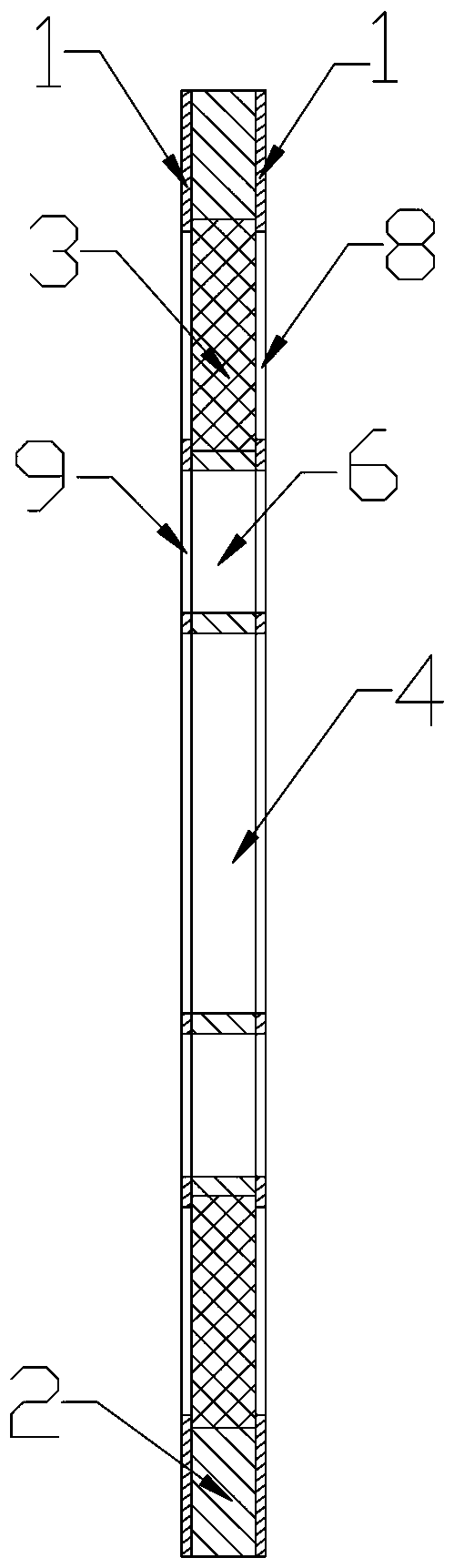

[0030] Such as Figure 1-3 As shown, the present invention includes an end cover 1, a bearing plate 2 and a magnetic steel 3. Both the end cover 1 and the bearing plate 2 are made of 316 stainless steel. Both the cover 1 and the bearing plate 2 are provided with a shaft hole 4 at the center, and eight magnetic steel holes 5 are evenly arranged on the bearing plate 2 along the circumferential direction. Setting, the magnetic steel hole 5 is a fan-shaped structure, the magnetic steel 3 is embedded in the magnetic steel hole 5, and twelve groups of internal heat dissipation holes 6 are evenly arranged on the bearing plate 2 along the circumferential direction, and the internal heat dissipation holes 6 are located between the shaft hole 4 and the magnetic steel hole 5 Between, each group of inner heat dissipation holes 6 includes a plurality of inner long ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com