A rock impact test device

A technology of collision test and rock, which is applied in the direction of testing the strength of materials with one-time impact force, can solve the problems of inability to realize single-point impact test of rock blocks, small speed range, immature technology, etc., and achieve single-point and double-point collision Test and realize the effect of high-precision control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

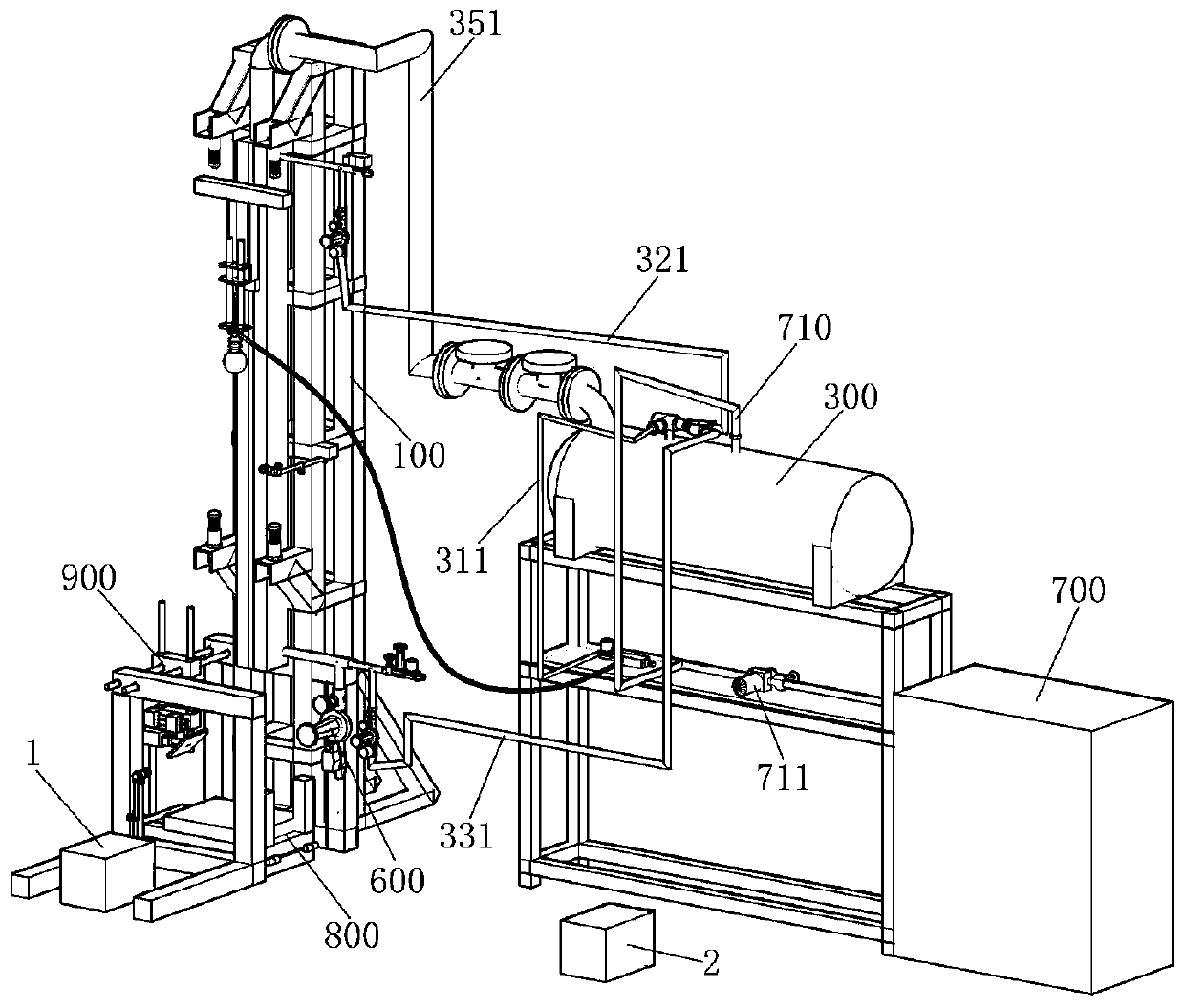

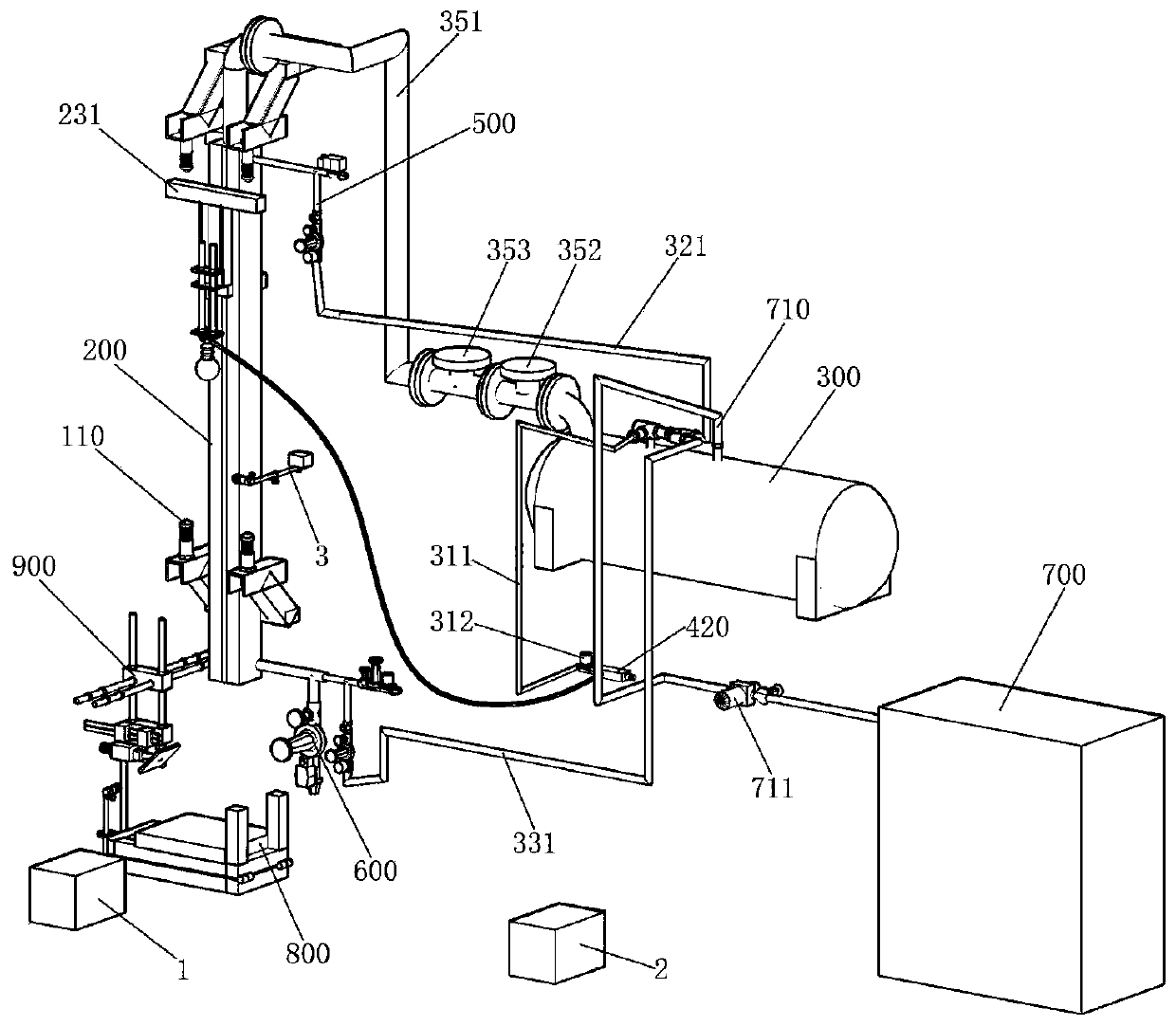

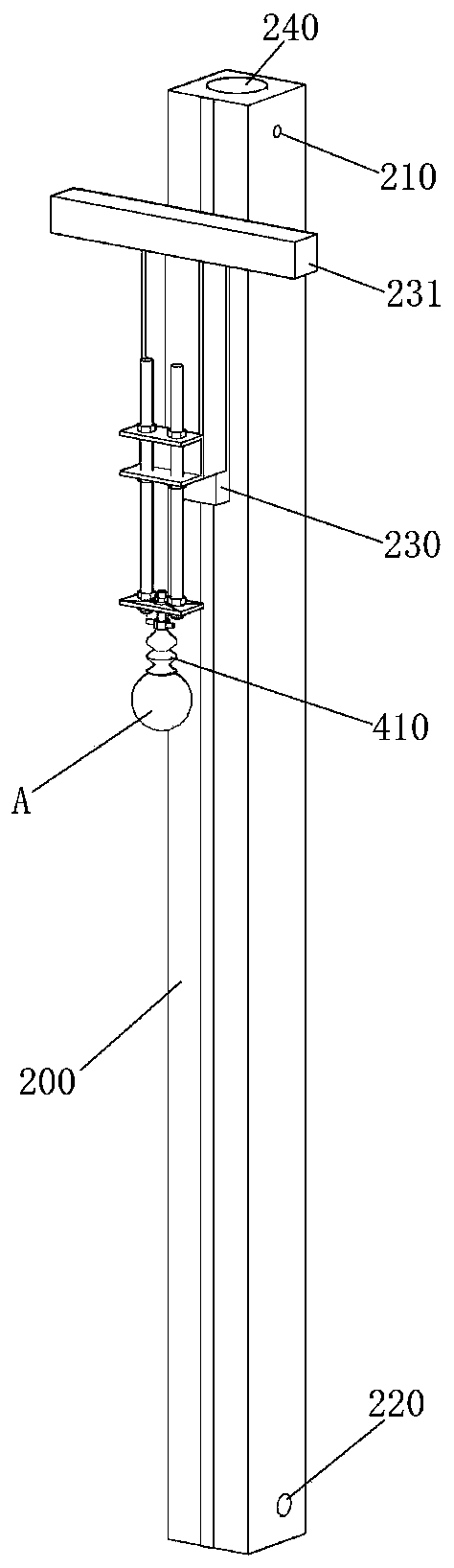

[0044] Such as Figure 1 to Figure 8 As shown, in order to show the main structure clearly, remove figure 1 The support structure in part gets figure 2 . A rock impact test device, characterized in that it includes a frame 100, a rodless cylinder 200, an air storage tank 300, a vacuum holding assembly, an upper intake and exhaust assembly 500, a lower intake and exhaust assembly 600, an air compressor 700, a collision The component 800, the first photoelectric sensor 3, the high-speed camera 1, and the controller 2 are characterized in that,

[0045] The rodless cylinder 200 is vertically and fixedly arranged on the frame 100, and the side walls at the upper and lower ends thereof respectively have an upper intake and exhaust port 210 and a lower intake and exhaust port 220;

[0046] The air storage tank 300 is provided with a tank intake pipe 340 and a tank air supply pipe, and the tank air supply pipe is provided with a first branch pipe 310, a second branch pipe 320 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com