Self-decompression multi-lip sealing bearing

A sealed bearing and self-relieving technology, which is applied to the sealing of the engine, bearing components, shafts and bearings, etc., can solve the problems of aggravated bearing wear, reduced sealing performance of the sealing ring, and shortened service life of the bearing, so as to enhance the overall performance. Effect of increasing sealing performance and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

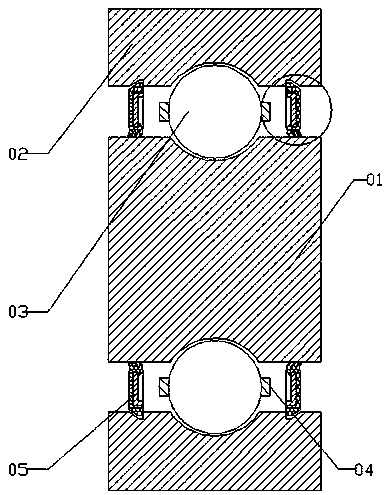

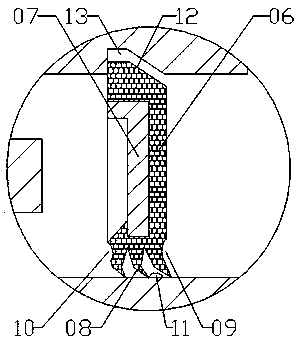

[0016] like Figure 1-2 , a self-relieving multi-lip seal bearing, which includes an inner ring 01, an outer ring 02, a steel ball 03 between the inner ring 01 and the outer ring 02, a cage 04 for installing the steel ball 03, and A sealing ring 05 is provided between the inner ring 01 and the outer ring 02 on both sides of the steel ball 03. The sealing ring 05 includes a sealing member 06 and an L-shaped skeleton 07. The L-shaped skeleton 07 is arranged inside the sealing member 06. The outer edge of the sealing member 06 is provided with a chuck 12, and the inner edge of the sealing member 06 is provided with a number of sealing lips 08 inclined outward, and the chuck 12 is installed in the groove arranged on the inner peripheral surface of the outer ring 02. In 13, the sealing lip 08 is in interference contact with the outer peripheral surface of the inner ring 01, and the sealing lip 08 is evenly distributed from the inside to the outside. The sealing lip 08 and the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com