Method and device for controlling an engine oil pump

A control method and engine technology, applied in the direction of controlling lubricant pressure, pressure lubricating safety devices, etc., can solve problems such as turbocharger lubrication failure, slow oil pressure build-up time, abnormal wear of solenoid valves and oil pumps, etc. Achieve the effect of expanding lubrication failure, avoiding solenoid valve failure, and saving fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Corresponding to Embodiment 1 of the present invention, Embodiment 2 of the present invention provides an engine oil pump control device, including:

[0042] The acquisition unit is used to acquire the current engine water temperature signal and the altitude signal of the vehicle;

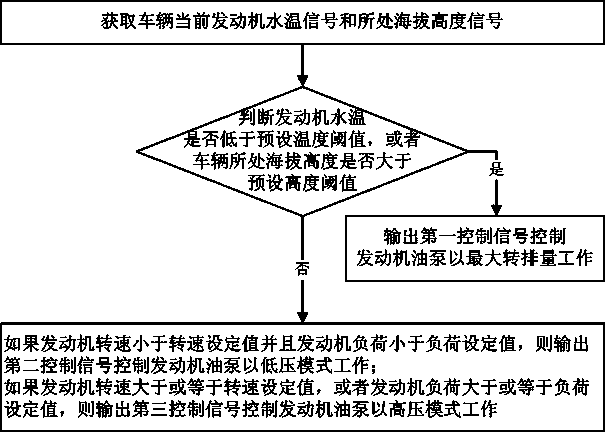

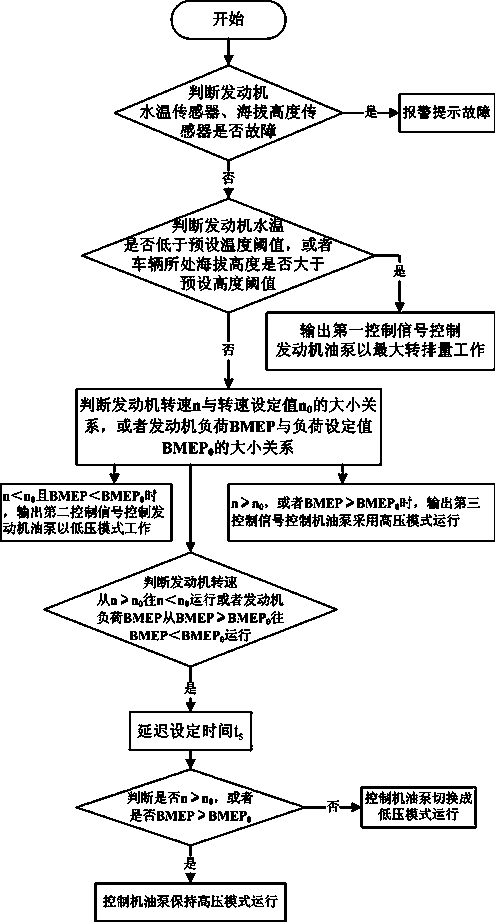

[0043] The control unit is used to output a first control signal to control the engine oil pump to work at the maximum rotation displacement when the engine water temperature is less than or equal to the preset temperature threshold, or the altitude of the vehicle is greater than or equal to the preset altitude threshold; and when the engine water temperature When the temperature is greater than the preset temperature threshold and the altitude of the vehicle is lower than the preset altitude threshold, if the engine speed is less than the speed setting value and the engine load is less than the load setting value, the second control signal is output to control the engine oil pump to work in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com