Short-line prefabrication assembly method for variable section segmental beam

A technology of prefabricated assembly and segmental beams, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of wasting time and achieve the effects of easy formwork adjustment, shortening the assembly period, and reducing the difficulty of construction coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

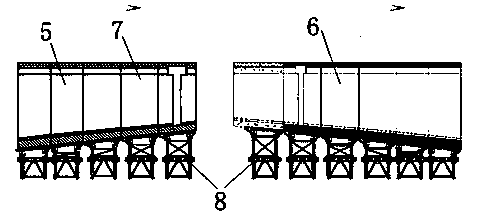

[0022] Such as Figure 1 to Figure 4 As shown, the present invention relates to a short-line prefabricated assembly method of segmental beams with variable cross-section, which is characterized in that it comprises the following steps:

[0023] Step 1, formwork partition design: Divide the overall formwork 1 into forward formwork 2 and reverse formwork 3 connected together, and divide the forward formwork 2 and reverse formwork 3 into 3 respectively according to the inclination and straightness of the main girder web A formwork prefabrication system 4, the formwork prefabrication system 4 is set according to the height difference of the segmental beam 5.

[0024] Step 2, fabrication of forward prefabricated beams: in the forward formwork 2, according to the transverse slope under the overall coordinates of the whole bridge, prefabricate the segmental b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com