Water inlet mechanism of water-saving industrial washing machine

A technology of water inlet mechanism and washing machine, which can be applied to other washing machines, washing devices, textiles and papermaking, etc. It can solve the problems of excessive water consumption and waste of water resources, and achieve the effects of clear principle, waste reduction and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

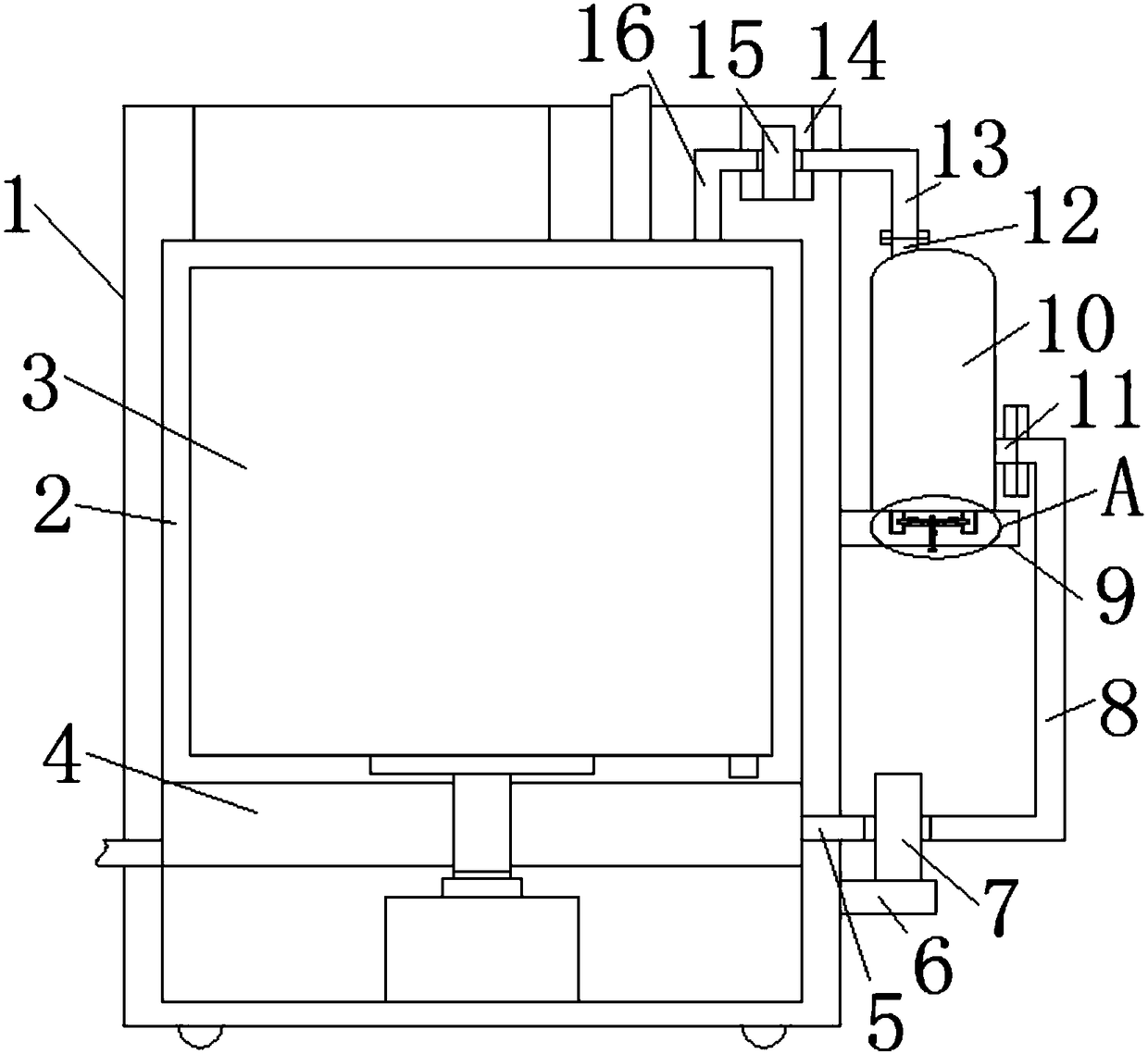

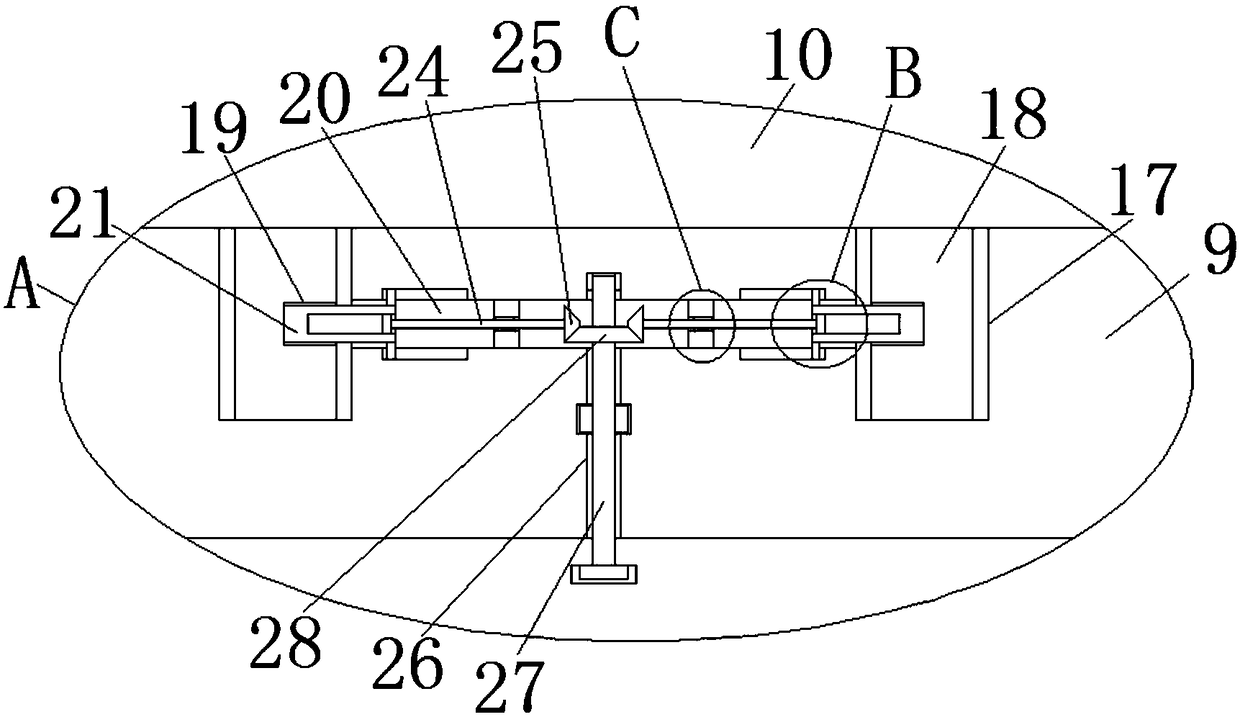

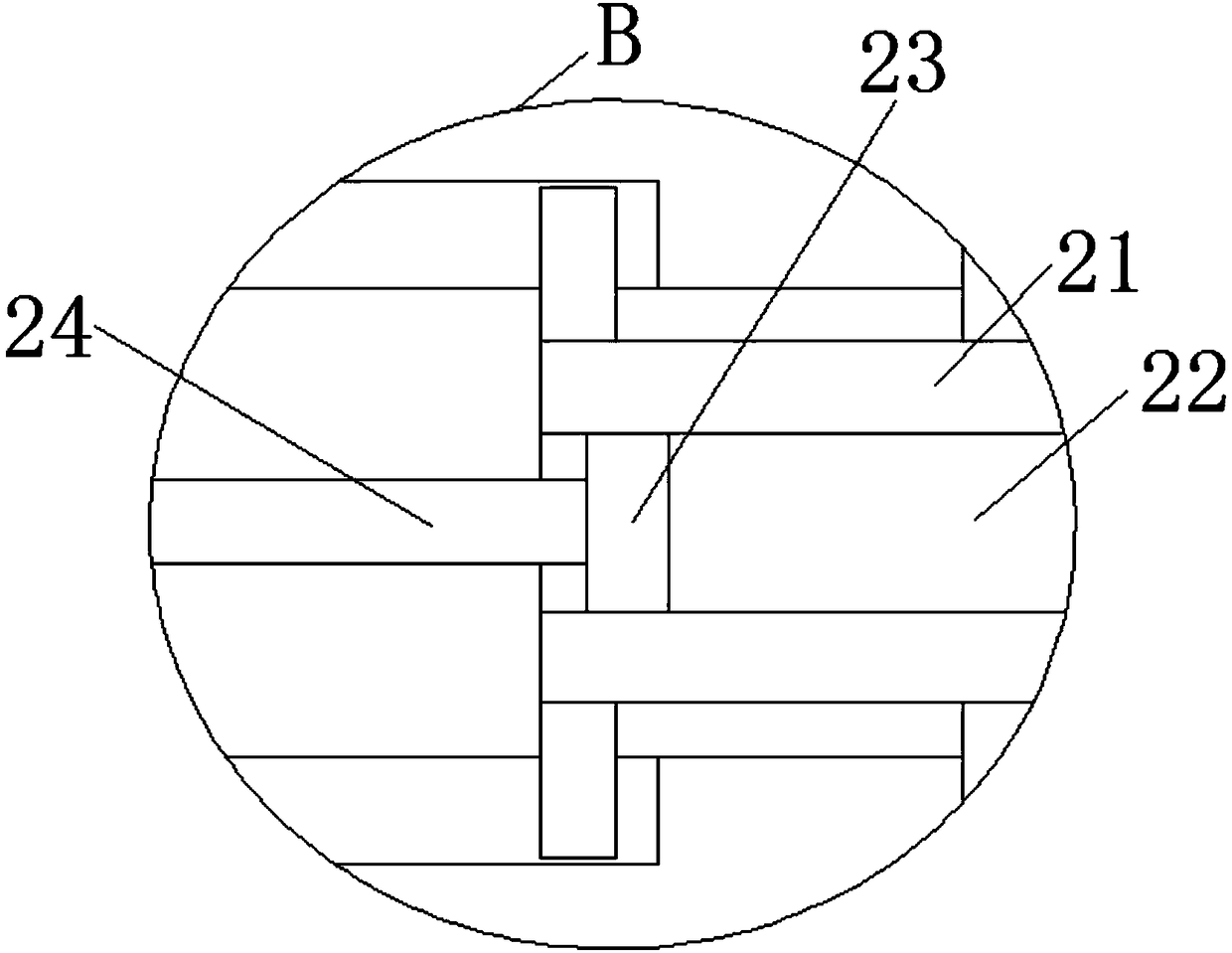

[0025] refer to Figure 1-5In this embodiment, a water inlet mechanism for a water-saving industrial washing machine is proposed, including a washing machine body 1, a fixed chamber 2 is provided on the washing machine body 1, a drum 3 is installed in the fixed chamber 2 for rotation, and a drum 3 is fixedly installed in the fixed chamber 2. There is a waste water tank 4 located below the drum 3, a fixing plate 6 is welded on one side of the washing machine body 1, a first circulating pump 7 is fixedly installed on the top of the fixing plate 6, and a first circulating pump 7 is fixedly connected to the suction port end of the first circulating pump 7. The hose 5, the first hose 5 communicates with the waste water tank 4, the drain end of the first circulating pump 7 is fixedly connected with the second hose 8, and one side of the washing machine body 1 is welded with a mounting seat located above the fixing plate 6 9. A filter 10 is provided on the top of the mounting base 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com