Numerical control spinning frame head transmission device

A transmission device and locomotive technology, applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problems of high labor intensity, gear damage, complex system mechanism, etc., and achieve simple and effective structure. The effect of prolonging the service life and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

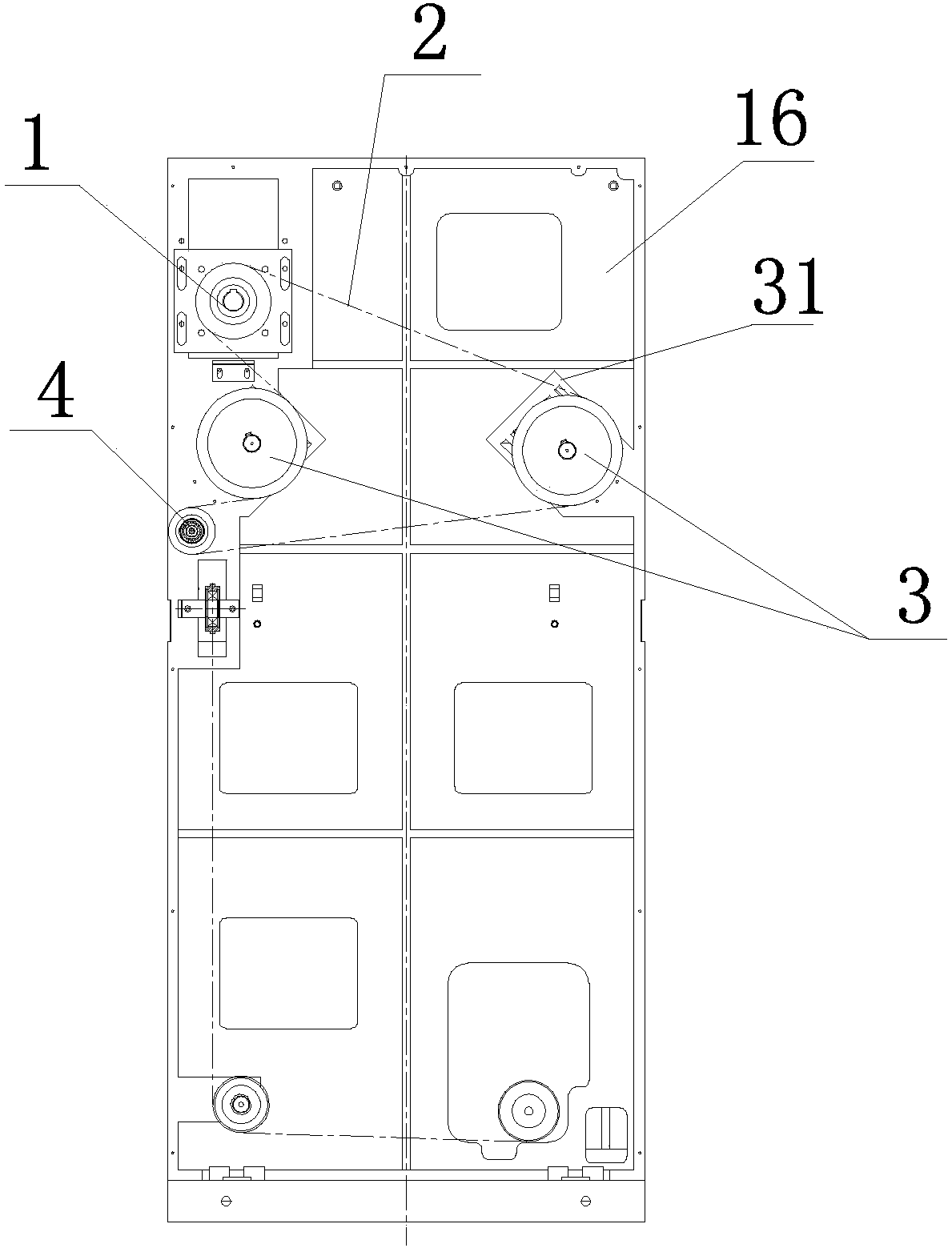

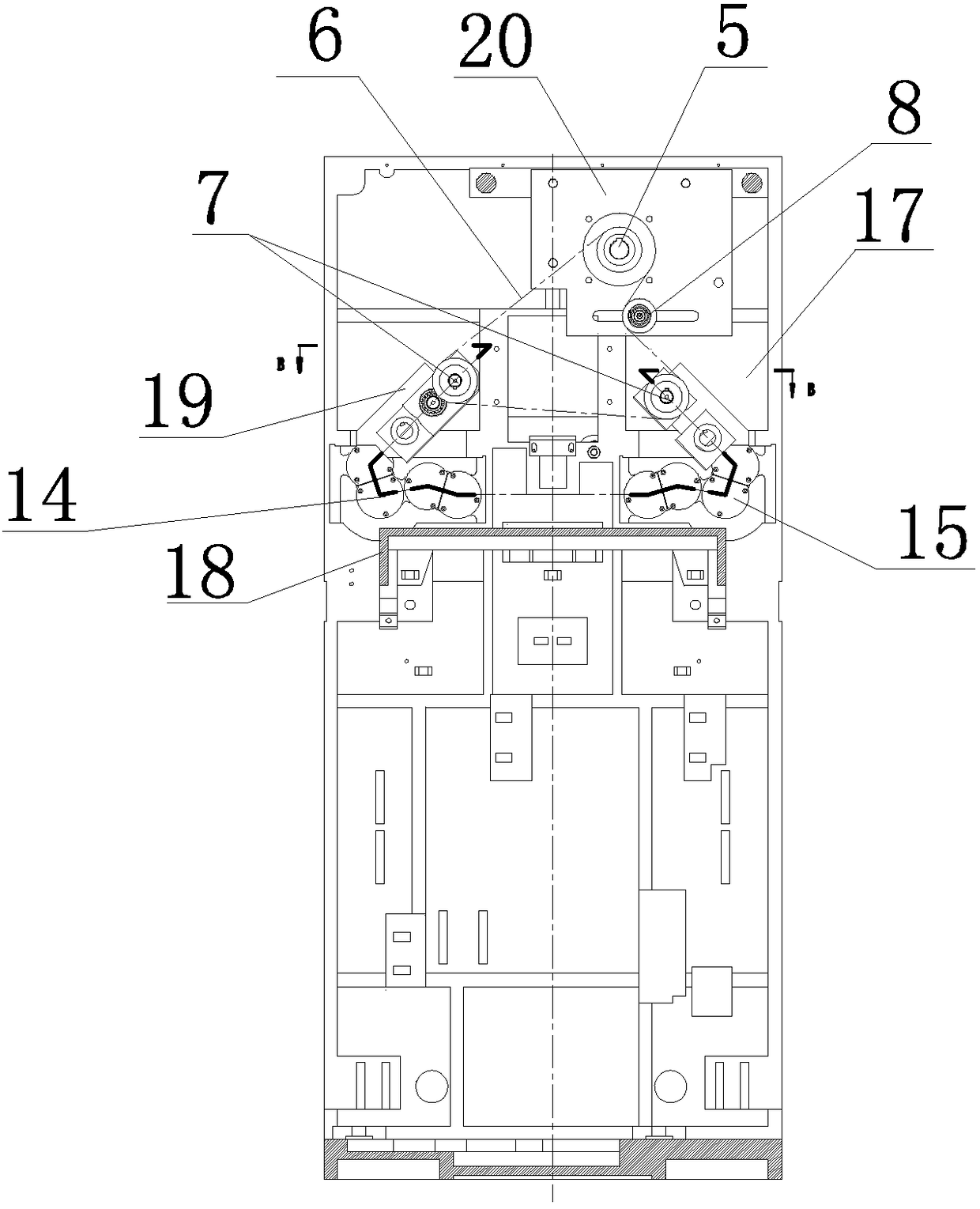

[0019] As shown in the accompanying drawings, the transmission device of the headstock of the CNC spinning machine has a structure including the front roller A, the middle roller B, the rear roller C, the outer vertical mounting plate 16 and the inner vertical mounting plate 17 on both sides, wherein the inner vertical mounting plate 17 and the inner vertical mounting plate 17 The outer vertical mounting plate 16 is arranged in parallel, the middle part between the outer vertical mounting plate 16 and the inner vertical mounting plate 17 is provided with a horizontal mounting plate 18, and the outer vertical mounting plate 16 is provided with a middle roller motor, a reduction box 1 and two middle roller synchronous pulleys 3. The synchronous belt pulley at the end of the output shaft of the middle roller motor and the reduction box 1 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com