Integrated fish ball division multi-station weighing machine and utilization method thereof

A multi-station and fish ball technology, applied in packaging, packaging fish, solid materials, etc., can solve the problems of large space occupation and low efficiency, and achieve the effects of saving space, improving shunting efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

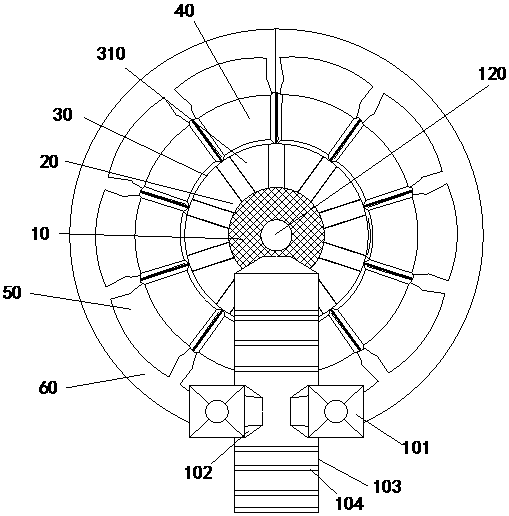

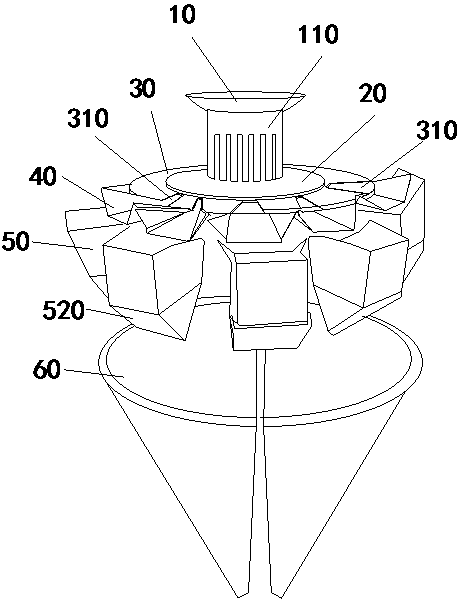

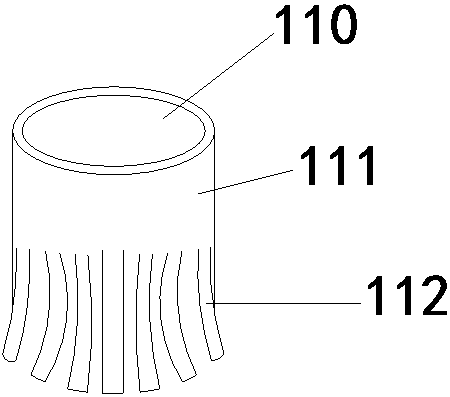

[0028] Such as Figure 1-8 As shown, a protective mechanism for preventing fish balls from rolling off during the dropping process includes a funnel-shaped fish ball dropping hopper 101 for introducing fish balls, and a discharge hopper 102 is arranged below the fish ball dropping hopper 101, and the outlet The discharge end of the hopper is provided with a lifter 103, and the discharge end of the lifter is provided with a first diverter plate 10 for fish balls to be exported, and the middle part of the first diverter plate 10 is provided with a diverter port 120, the A second diverter plate 20 is arranged below the first diverter plate, and a diverter pipe 110 fixed below the diverter port for leading out fish balls is arranged between the second diverter plate 20 and the first diverter plate 10. The disc 20 is a disc body with an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com