Lanthanum carbonate-nerchinskite composite material as well as preparation method and application thereof

A technology of lanthanum oxycarbonate and composite materials, applied in the field of environmental pollution treatment, can solve problems such as phosphate adsorption that has not been reported, and achieve the effects of facilitating diffusion and mass transfer, optimization of loadability, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Mix 10g of halloysite with 10g of lanthanum nitrate hexahydrate and 2g of glycine, add 50ml of deionized water, and sonicate for 10min.

[0028] 2) Put the suspension obtained in step 1) in a 500mL suction filter bottle to vacuumize for 10min, repeat 3 times, then place the suspension in an oven and bake at 80°C for 2 hours to obtain a dry sample.

[0029] 3) The dried sample obtained in step 2) was placed in a tube furnace, purged with nitrogen gas at a flow rate of 100ml / min for 30min, and then kept at a constant temperature of 300°C for 2h to obtain a lanthanum oxycarbonate-halloysite composite material.

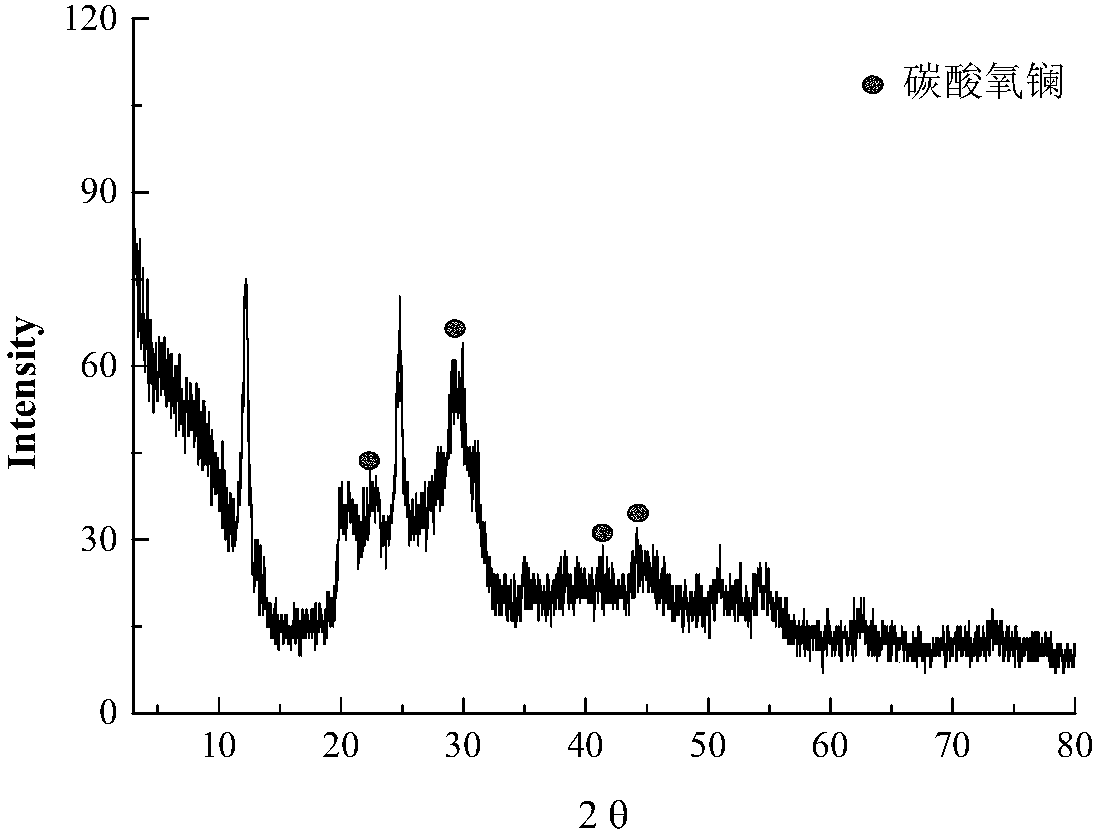

[0030] Utilize X-ray diffraction (XRD) to measure the structure of gained lanthanum oxycarbonate-halloysite composite material, the result shows that its X-ray diffraction pattern ( figure 1 ) appeared a characteristic diffraction peak attributed to lanthanum oxycarbonate.

[0031] Batch adsorption experiments were used to test the phosphorus adsorption capacit...

Embodiment 2

[0033] 1) Mix 20g of halloysite with 15g of lanthanum nitrate hexahydrate and 15g of glycine, add 50ml of deionized water, and sonicate for 20min.

[0034] 2) Put the suspension obtained in step 1) into a 500mL suction filter bottle and vacuumize for 15min, repeat 3 times, then place the suspension in an oven and bake at 120°C for 5 hours to obtain a dry sample.

[0035] 3) The dried sample obtained in step 2) was placed in a tube furnace, purged with nitrogen gas at a flow rate of 150ml / min for 30min, and then kept at a constant temperature of 400°C for 2h to obtain a lanthanum oxycarbonate-halloysite composite material.

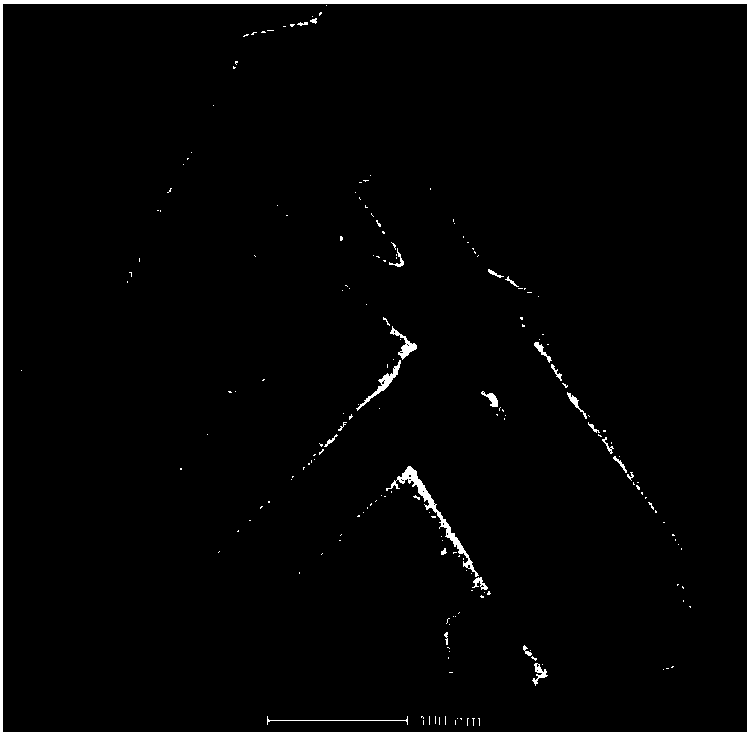

[0036] Through transmission electron microscopy (TEM) analysis, it was found that lanthanum oxycarbonate was uniformly loaded in the inner and outer tubes of halloysite ( figure 2 ). Batch adsorption experiments were used to test the phosphorus adsorption capacity of the lanthanum oxycarbonate-halloysite composite material, and the adsorption capacity for...

Embodiment 3

[0038] 1) Mix 30g of halloysite with 18g of lanthanum nitrate hexahydrate and 9g of glycine, add 30ml of deionized water, and sonicate for 30min.

[0039] 2) Put the suspension obtained in step 1) in a 250mL suction filter bottle and vacuumize for 30min, repeat 3 times, then place the suspension in an oven, and bake at 130°C for 4 hours to obtain a dry sample.

[0040] 3) Place the solid obtained in step 2) in a tube furnace with a nitrogen flow rate of 160ml / min. After nitrogen protection for 30 minutes, keep the temperature at 450°C for 2 hours. After the tube furnace cools down, take out the sample to obtain lanthanum oxycarbonate - Halloysite composite.

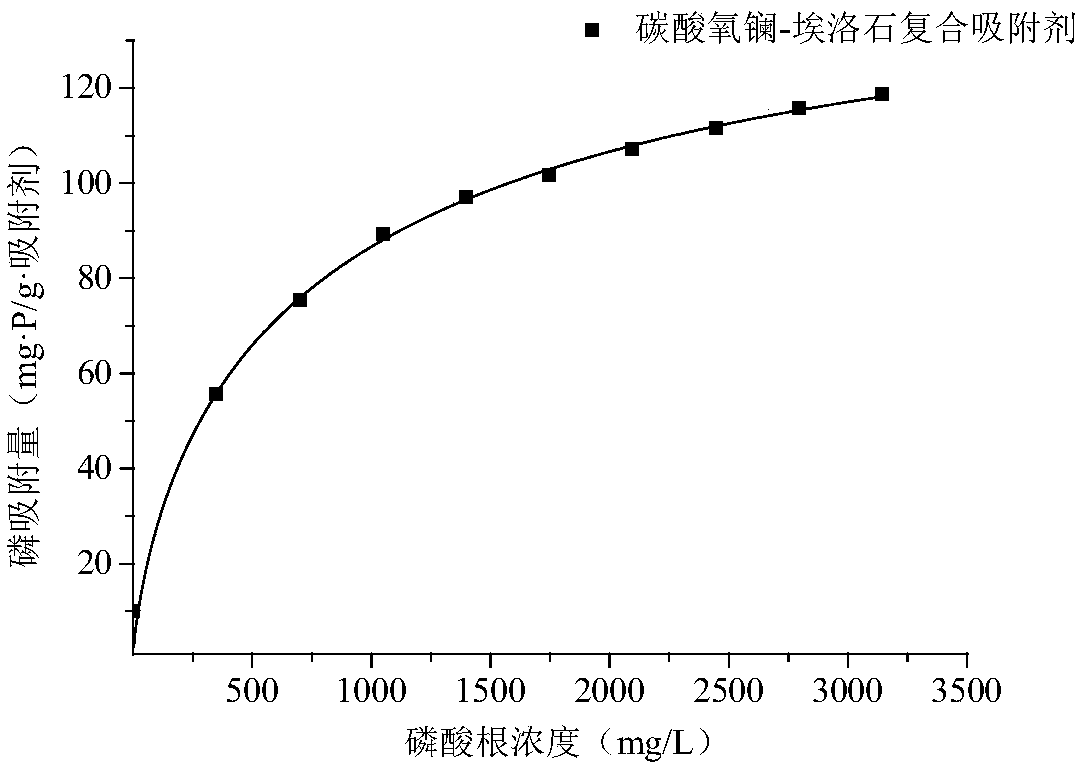

[0041] The phosphorus adsorption capacity of this lanthanum oxycarbonate-halloysite composite material is tested by batch adsorption experiment, and its adsorption capacity for phosphate is 120mg·P / g·adsorbent ( image 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com