Three-degree-of-freedom spherical stator base body of ultrasonic motor stator and excitation method of stator base body

A spherical stator and motor stator technology, which is applied in the directions of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc. and other problems, to achieve the effect of simple and compact structure, easy miniaturization, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

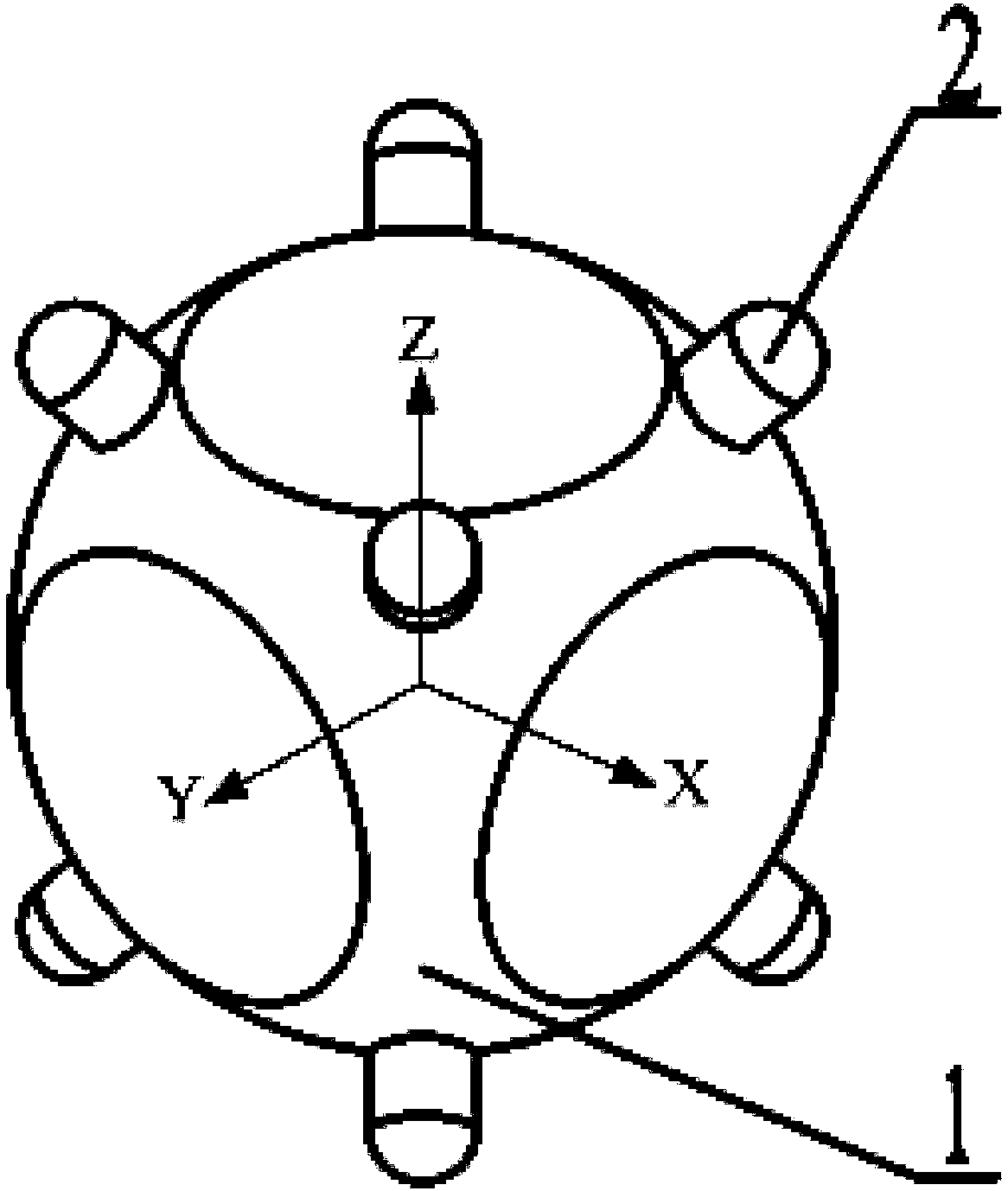

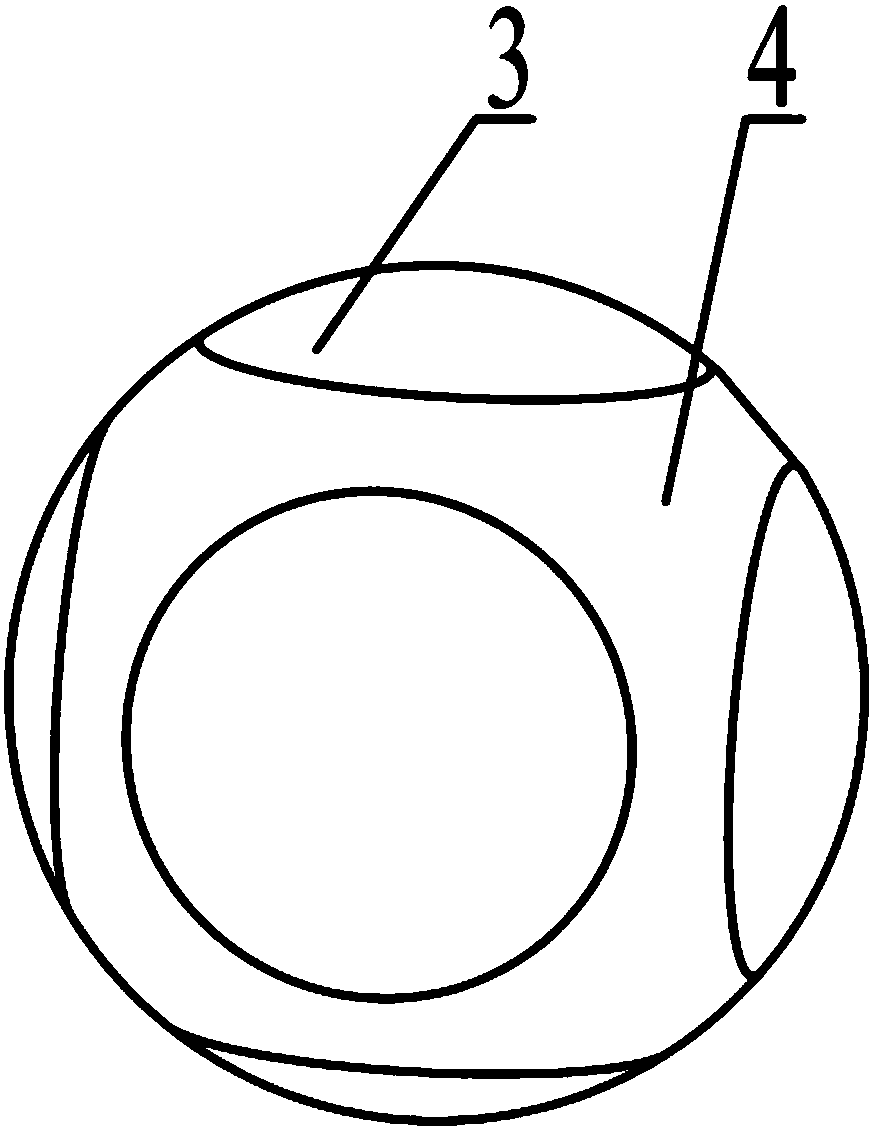

[0019] Specific implementation mode one: refer to Figure 1 to Figure 3 Describe this embodiment in detail, the three-degree-of-freedom spherical stator ultrasonic motor stator base described in this embodiment includes a piezoelectric ceramic spherical shell 1 and eight driving feet 2,

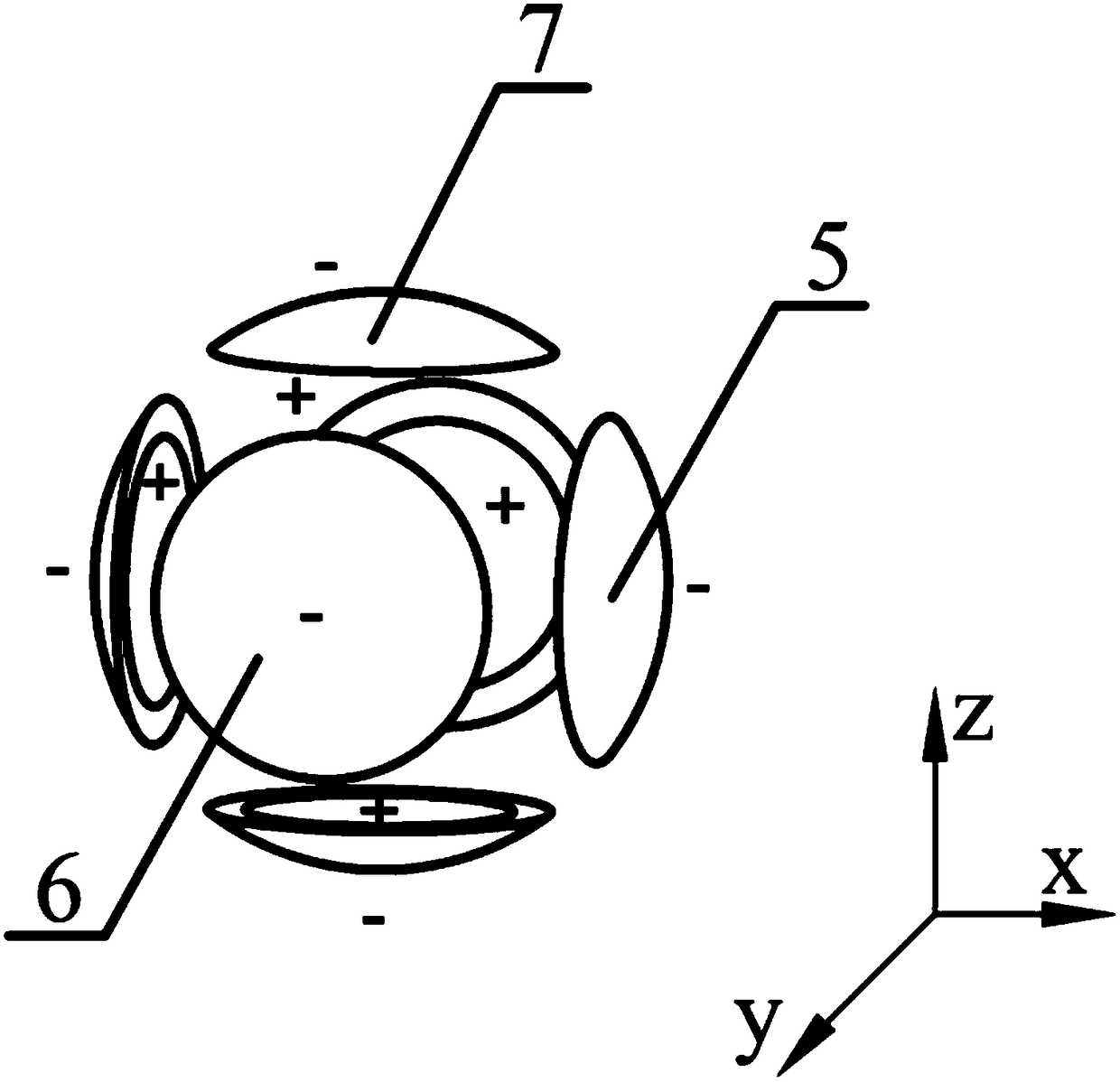

[0020] A pair of electrode partitions 5 in the direction of the x-axis, a pair of electrode partitions 6 in the direction of the y-axis, and a pair of z-axis direction of electrode partition 7,

[0021] The blank area between all the electrode partitions is the non-electrode area 4,

[0022] The polarization direction of each pair of electrode partitions is the same, and all electrode partitions are polarized along the thickness direction of the ball diameter,

[0023] The eight driving feet 2 are evenly arranged on the non-electrode area 4, and the spatial phase differences between the eight driving feet 2 and the electrode partition 5 in the x-axis direction, the electrode partition 6 in ...

specific Embodiment approach 2

[0026] Embodiment 2: The excitation method of the stator base of the three-degree-of-freedom spherical stator ultrasonic motor described in this embodiment is based on the three-degree-of-freedom spherical stator stator base of the ultrasonic motor described in Embodiment 1. The excitation method can Excite the three-degree-of-freedom spherical stator ultrasonic motor stator base to realize three-degree-of-freedom movement, and the three degrees of freedom include elliptical rotation around the x, y and z axes;

[0027] The excitation method of the three-degree-of-freedom spherical stator ultrasonic motor stator base driving the motor rotor to rotate around the x-axis:

[0028] A phase excitation voltage is applied to the electrode partition 6 in the y-axis direction and the electrode partition 7 in the z-axis direction, so that the piezoelectric ceramic spherical shell 1 produces a yaw-like vibration mode along the y-axis and z-axis directions, so that along the y-axis and z-a...

specific Embodiment approach 3

[0038] Specific implementation mode three: refer to Figure 4 Describe this embodiment in detail. This embodiment is to further explain the excitation method of the stator base of the three-degree-of-freedom spherical stator ultrasonic motor described in the second embodiment. In this embodiment, the electrode partitions 6 and z in the y-axis direction The excitation voltage with an amplitude of 60V is applied to the electrode partitions 7 in the axial direction, and the positive and negative poles of the anti-phase voltage with a phase amplitude of 60V are respectively connected to a pair of electrode partitions 6 in the y-axis direction, and the opposite phase voltage with an amplitude of 60V is respectively connected to a pair of electrode partitions 6 in the y-axis direction. The positive and negative poles of the phase voltage are respectively connected to a pair of electrode partitions 7 in the z-axis direction.

[0039] In this embodiment, if Figure 4 As shown, the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com