Fuse carrying device

A technology of bearing devices and fuses, applied in emergency protection devices, electrical components, circuits, etc., can solve the problems of unsatisfactory contact conduction effect, high material cost and processing cost, complex structure and process, etc., to save production costs , good electrical conductivity and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

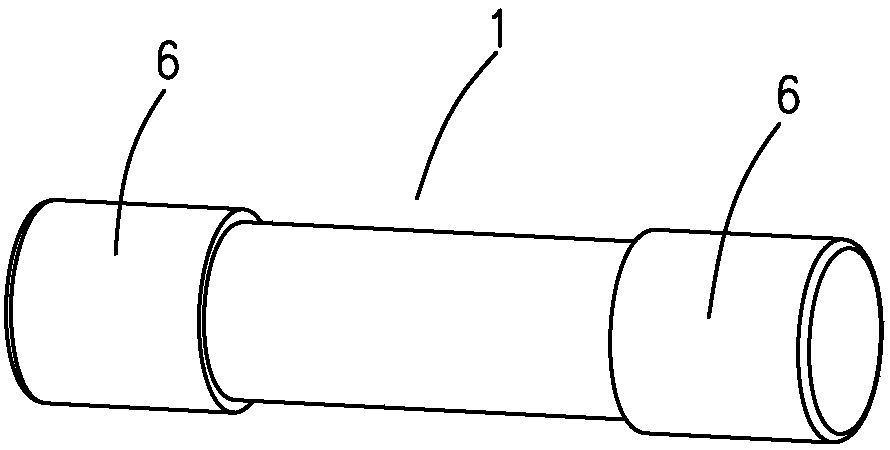

[0030] as follows Figure 1 to Figure 10 The preferred embodiment of the fuse carrying device of the present invention is shown as an example to illustrate the specific implementation of the present invention.

[0031] The fuse carrying device of the present invention such as Figure 2 to Figure 4 shown, including the figure 1 The carrier (2) of the cylindrical standard fuse (1) shown is for the carrier (2) to be inserted into the fixed seat (3) that is pulled out, and the carrier (2) and the fixed seat (3) are both Made of insulating material; the carrier (2) includes a cover (4) and a carrier (5) extending downward from the cover (4); the fuse carrying device also includes two pieces arranged at intervals The contact piece (7) made of conductive metal is used to clamp the columnar conductive metal contact caps (6) at both ends of the fuse (1), and the contact piece (7) is in contact with the fuse (1) to be contacted. The axes are set perpendicular to each other. Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com