Lens conforming to retinal resolution, dispensing prescription and manufacturing method thereof

A manufacturing method and technology of resolution, applied in glasses/goggles, optical components, instruments, etc., can solve the problems of large manufacturing and assembly work differences, information communication errors, and glasses failing to meet the requirements of retinal resolution, etc. The difference is small and the effect of highlighting the manufacturing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

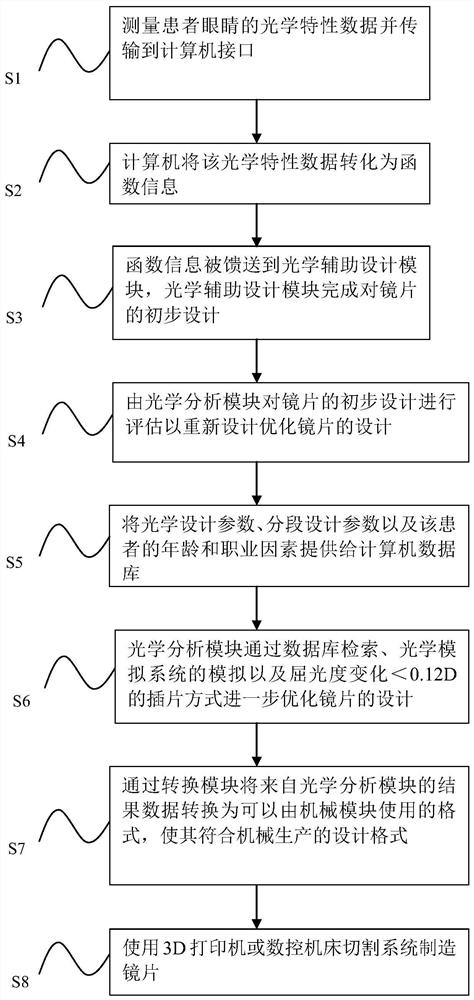

[0033] S1, Measure the optical properties of the patient's eye through a high-precision customized focal meter or wavefront sensor and generate a feature data set that is transmitted to a computer interface, including but not limited to wavefront aberration and corneal topography data for the creation of a computational model eye The basics. Among them, the measurement accuracy of aberration is expressed as focal difference <0.06D. The high-precision customized focal meter or wavefront sensor here refers to an optical instrument that can meet the above-mentioned measurement accuracy.

[0034] S2, the computer converts the optical characteristic data into function information.

[0035] S3, the function information is fed to the optical calculation aided (CAD) design module, and the optical aided design module completes the preliminary design of the lens through the optical design software, and the design includes but is not limited to the double-sided free-form surface design ...

Embodiment 2

[0045] Example 2 - Example 4 Example 1 is further illustrated by a real fitting and manufacturing example.

[0046] Example 2

[0047] Patient 1 (44 years old), optometry data: left eye: -2.65, right eye: -2.65.

[0048] Input the optometry data into the computer, and the computer corrects the initial data according to the fact that the patient works as a clerical worker and uses his eyes at close range, and the corrected parameters are obtained as left eye: -2.53 and right eye: -2.53. For the case where the value of the diopter is less than -5.00, a material with a refractive index of 1.597 is selected for the next step of the model design process. Through the optical simulation system, the correction effect after the patient wears it is simulated, and the combination of the actual wearing and correction of the optometry film in the 5-degree change interval is used to further confirm the comfort of use.

[0049] After obtaining the final 3D model, according to the design ch...

Embodiment 3

[0051] Using the technical solution of Example 1, the best correction solution for patient 2 was obtained: left eye: -2.55, right eye: -2.55.

[0052] Use the current national standard 25-degree optometry film for optometry and correction, which can only be selected between left eye: -2.50, right eye: -2.50 or left eye: -2.75, right eye: -2.75;

[0053] Optometry and correction are performed with a 10-degree interval optometry sheet, which can only be selected between left eye: -2.50, right eye: -2.50 or left eye: -2.60, right eye: -2.60;

[0054] Using the optometry film in the 5-degree interval for optometry and correction, the optometry data can be accurately obtained and corrected as follows: left eye: -2.55, right eye: -2.55.

[0055] Medical data proves that the minimum resolution of the human eye for vision correction is 0.0625D, so the optometry and correction will be carried out with a 5-degree interval to achieve the theoretically optimal correction plan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com