Hydraulic-magnetic driving borehole cleaning tool magnetic torque test apparatus and test method

A technology for cleaning tools and torque testing, applied in force/torque/power measuring instruments, measuring devices, force sensors related to bearings, etc., can solve the problems of lack of on-site experimental verification, etc., to facilitate the measurement of rotation angle and pressure values, The effect of improving accuracy and simplifying the torque measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing, the present invention will be further described:

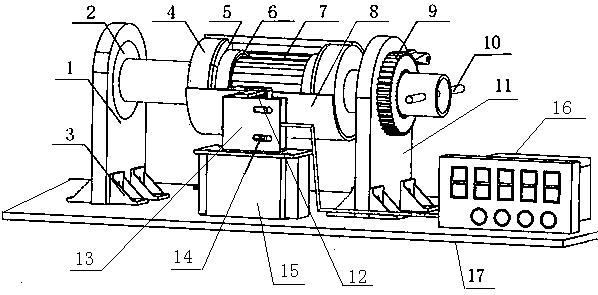

[0049] combine Figure 1-Figure 17 As shown, this hydraulic-magnetic drive wellbore cleaning tool magnetic torque testing device includes a magnetic drive assembly, a brake assembly, a pressure measurement assembly, a front support plate, a rear support plate 1, a test bench, a front support plate 11, and a rear support plate All are fixed on the test bench 17 through stainless steel corner fittings 3, and the magnetic drive assembly is installed between the front support plate 11 and the rear support plate 1 through its rotating shaft. The lower surfaces meet, and the pressure bearing plate 12 is in a horizontal state.

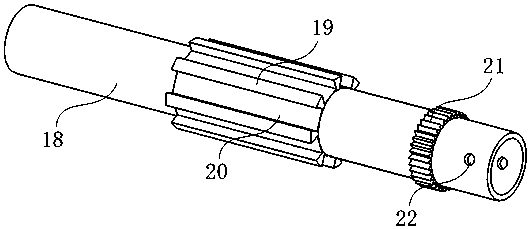

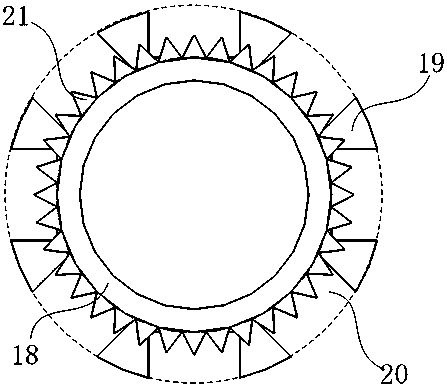

[0050] refer to figure 2 and image 3 , the magnetic transmission assembly includes an inner magnetic shaft 7 and an outer magnetic shaft 8, the inner magnetic shaft 7 is installed at the corresponding position in the cylinder body of the outer magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com