Printing paper tape lateral vibration testing device and testing method

A technology of lateral vibration and testing device, applied in the field of lateral vibration testing of paper tape and lateral vibration testing device of printed paper tape, can solve the problem that the testing device cannot work normally, single edge detection, center detection, line detection, detection lag, etc. problems, achieve flexible clock module configuration and interrupt function, realize human-computer interaction, and improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

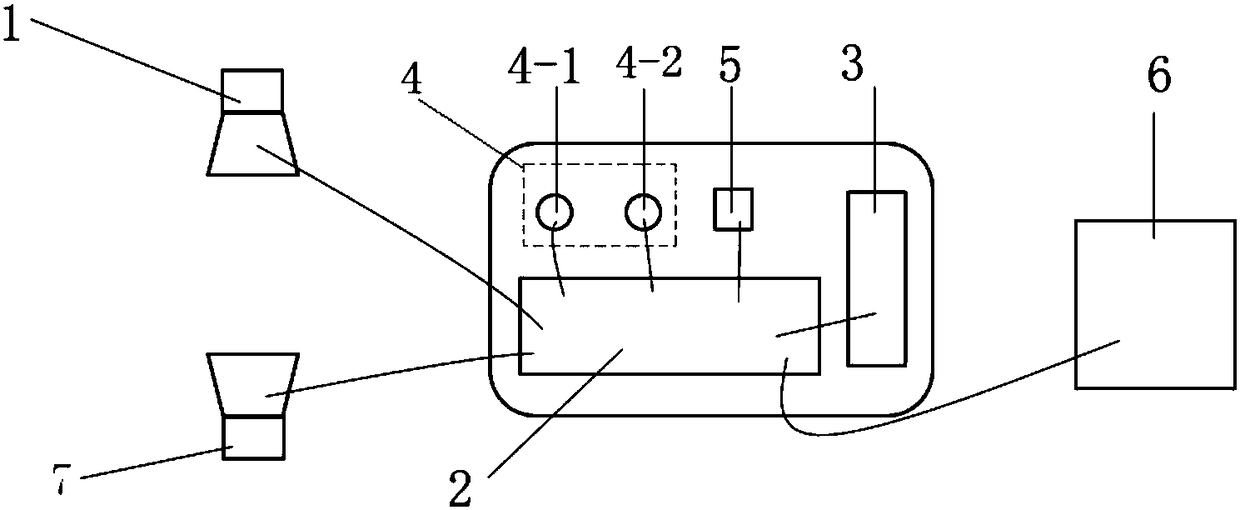

[0047] The invention provides a printing paper strip transverse vibration testing device, such as figure 1 As shown, it includes an upper ultrasonic sensor 1, a controller 2 and a centralized controller 6 connected in sequence, the controller 2 is also connected with a lower ultrasonic sensor 7, and the controller 2 is provided with a liquid crystal display 3, an indicator light unit 4, and an alarm 5 .

[0048] The models of the upper ultrasonic sensor 1 and the lower ultrasonic sensor 7 are the same, both

[0049] UNAR 18U6903 / S14G ultrasonic sensor.

[0050] Controller 2 is MSP430F149 single-chip microcomputer.

[0051] The liquid crystal display 3 is a 3.2-inch LCD1602 liquid crystal display.

[0052] The indicator light unit 4 includes a first indicator light 4-1 and a second indicator light 4-2. The model of the first indicator light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com