Closed-loop double-evaporator drying heat pump and volatile oil recovery method

A technology of double evaporators and evaporators, which is applied in drying, drying machines, drying solid materials, etc., can solve the problems that cannot satisfy the liquefaction and recovery of volatile oil, it is difficult to ensure continuous heating and dehumidification, closed-loop drying, etc., and achieve rapid heating and temperature Humidity control, guaranteed operating performance, and improved heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

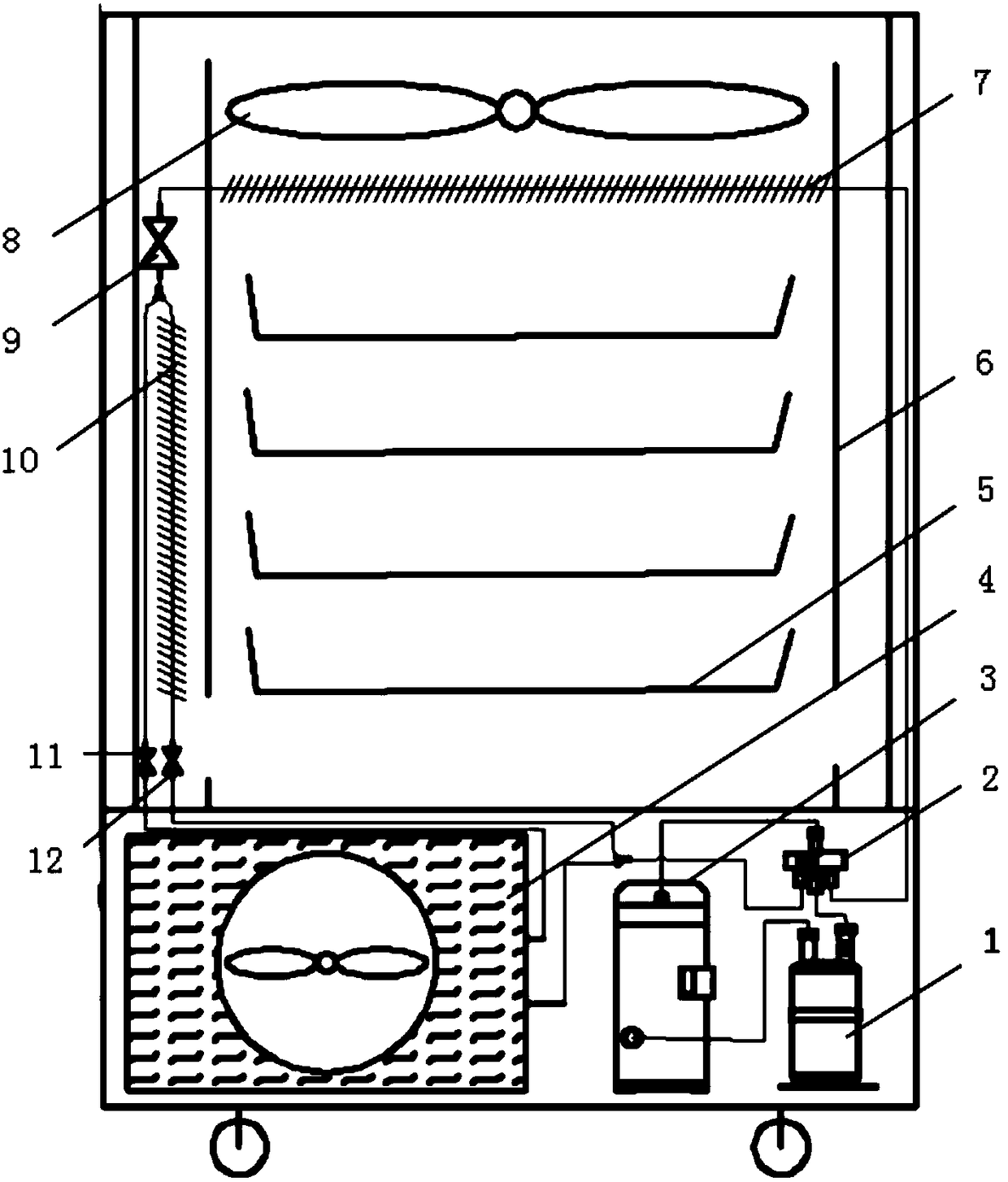

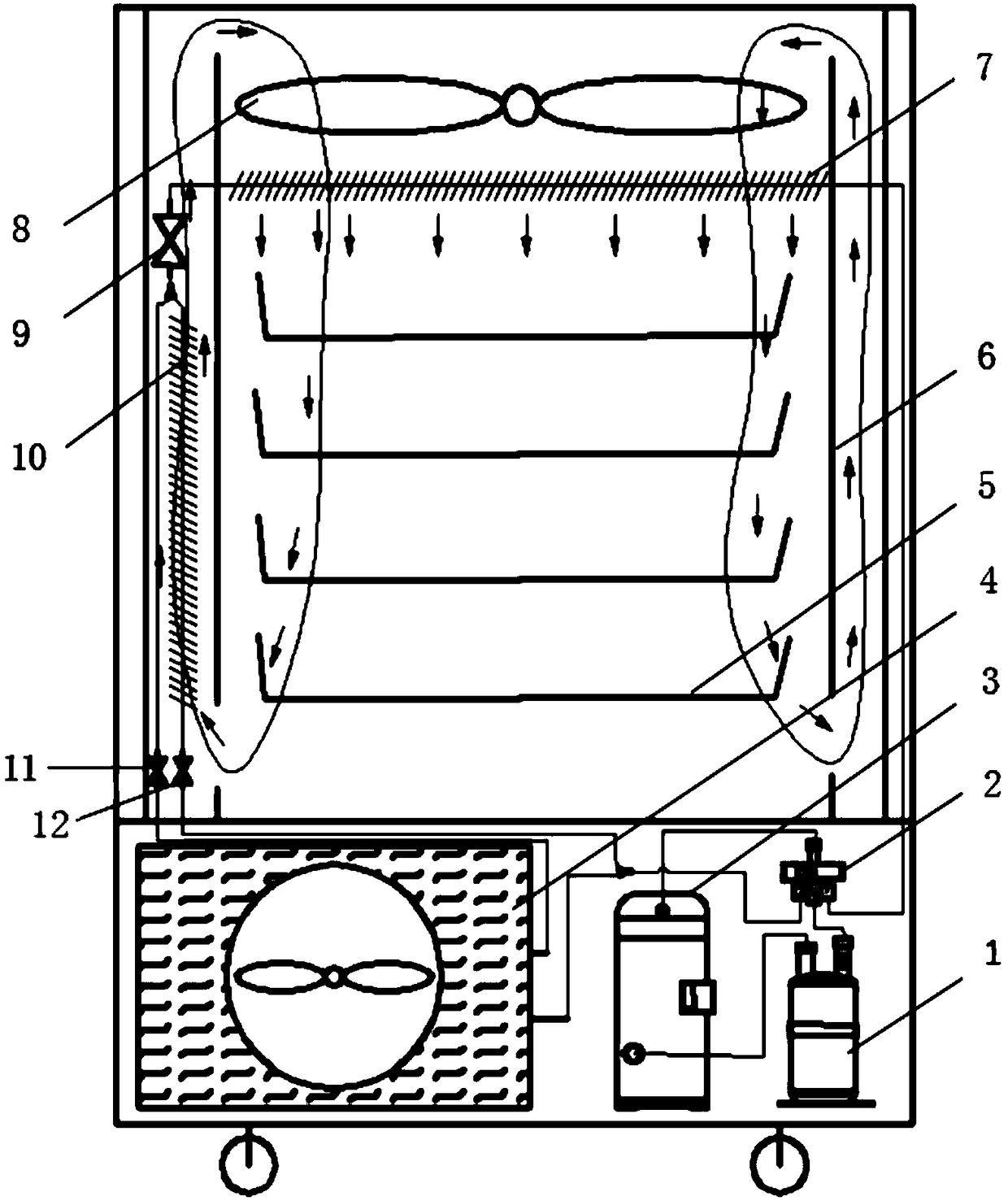

[0040] like figure 1 As shown, a closed-loop double evaporator drying heat pump is composed of a fluorine system and a dryer frame 6. The double evaporator drying heat pump can be an integrated machine, or a heat pump main unit composed of a fluorine system and a drying machine. room combination; the dryer frame 6 constitutes a closed drying chamber and an indoor medium circulation channel through a partition; the main evaporator 4 and the secondary evaporator 10 are connected in parallel to form the low-pressure area of the fluorine system; the main evaporator 4 is installed in Outside the drying room, the secondary evaporator 10 and the condenser 7 are installed in the drying room; the first outlet of the compressor 3 is connected to the condenser 7 through the four-way reversing valve 2, and the condenser 7 passes through the throttling device 9 and then has two A parallel branch, one way is connected to the secondary evaporator 10, and the other is connected to the main ...

Embodiment 2

[0045] When the material is in the late stage of drying, the humidity of the material is low, and the temperature in the drying room is high, and constant temperature dehumidification is carried out to realize energy-saving drying. In the dehumidification mode, the refrigerant does not flow into the main evaporator 4. At this time, the refrigerant flow direction is: compressor 3 → four-way reversing valve 2 → condenser 7 → throttling device 9 → secondary evaporator 10 → second electromagnetic two-way valve 12 → Four-way reversing valve 2 → Gas-liquid separator 1 → Compressor 3.

Embodiment 3

[0047] Closed loop double evaporator drying heat pump for volatile oil recovery:

[0048] The frame 6 of the dryer constitutes a plurality of medium circulation channels. Driven by the axial flow fan 8, the medium flows through the surface of the condenser 7 to heat the medium, and the hot air transfers heat to the material on the tray 5, heating the material, and making the moisture in the material The volatile oil diffuses into the medium to form hot and humid oily air. The medium circulation channel is divided into a local low-temperature zone and a pure medium channel. The local low-temperature zone is formed by installing a secondary evaporator 10 in the medium circulation channel. The pure medium channel is only used as a circulation of the medium. Without liquefaction treatment, because of the secondary evaporator in the local low-temperature area, the wind resistance is greater than that of the pure medium channel, so the circulating medium in the drying chamber is main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com