Multiphase pump impeller structure for fish farming industry

A mixed-transport pump and impeller technology, which is applied to components, pumps, and pump components of pumping devices for elastic fluids, can solve the problems of inability to realize gas-liquid-solid or gas-liquid mixed transportation, flow and head that cannot meet the needs, Unable to transport solids and other problems, to achieve the effect of reducing fish farming costs, improving fish farming efficiency, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is specifically described below through the examples, the examples are only used to further illustrate the present invention, and cannot be interpreted as limiting the protection scope of the present invention, some non-essential improvements made by those skilled in the art according to the contents of the present invention And adjustments also belong to the protection scope of the present invention.

[0032] In conjunction with the accompanying drawings.

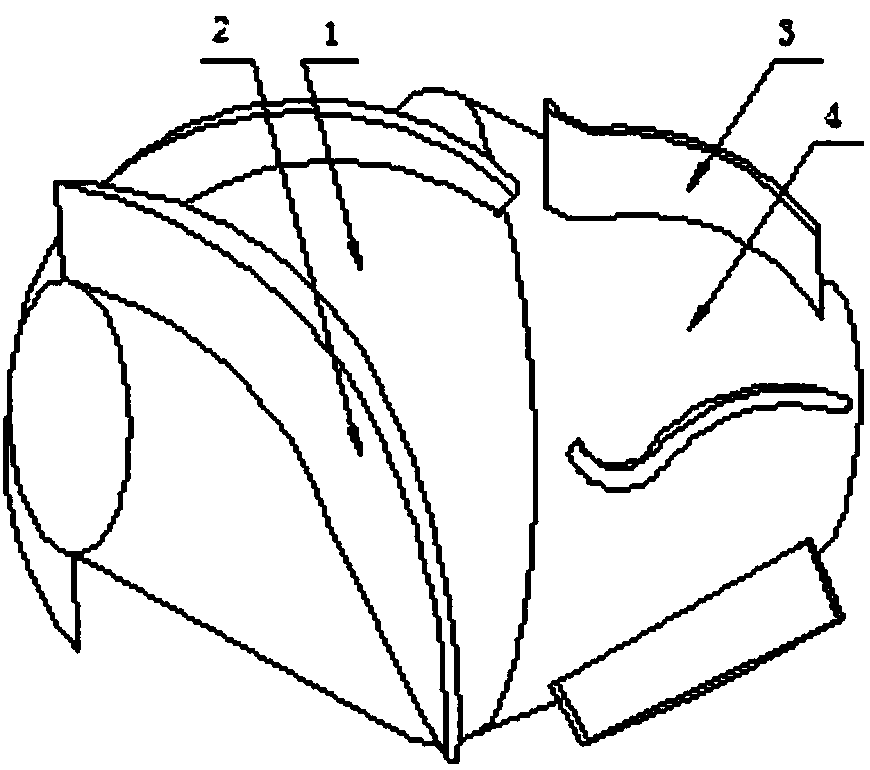

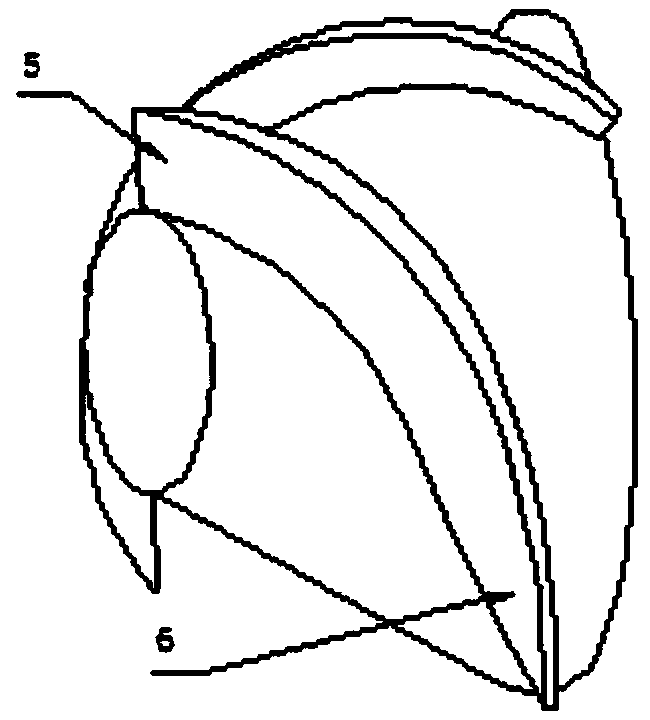

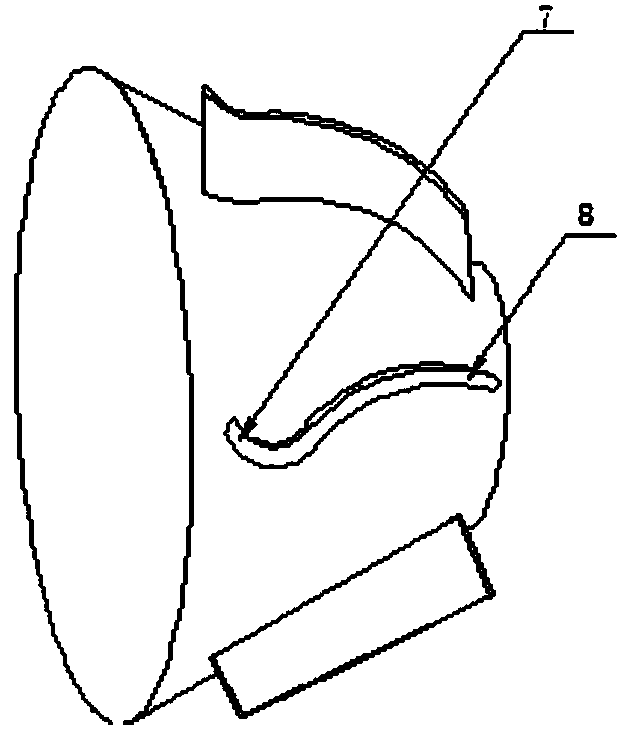

[0033] As shown in the figure, the mixed pump impeller structure used in fish farming, the mixed pump includes at least one set of compression stages composed of a moving impeller and a stationary impeller, each moving impeller consists of a moving impeller hub 1 and a moving impeller blade 2. Each stationary impeller is composed of the stationary impeller hub 4 and the stationary impeller blade 3. The diameter at both ends of each compression stage in the axial direction is smaller than the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com