Snow making system for performance testing device of freezer

A technology for testing devices and refrigerators, which is applied in the testing and application of measuring devices, machines/structural components, etc., can solve the problems of water temperature affecting snowmaking effect, lack of temperature sensors, and large water tank volume, so as to avoid heat loss and ensure The effect of temperature and full contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

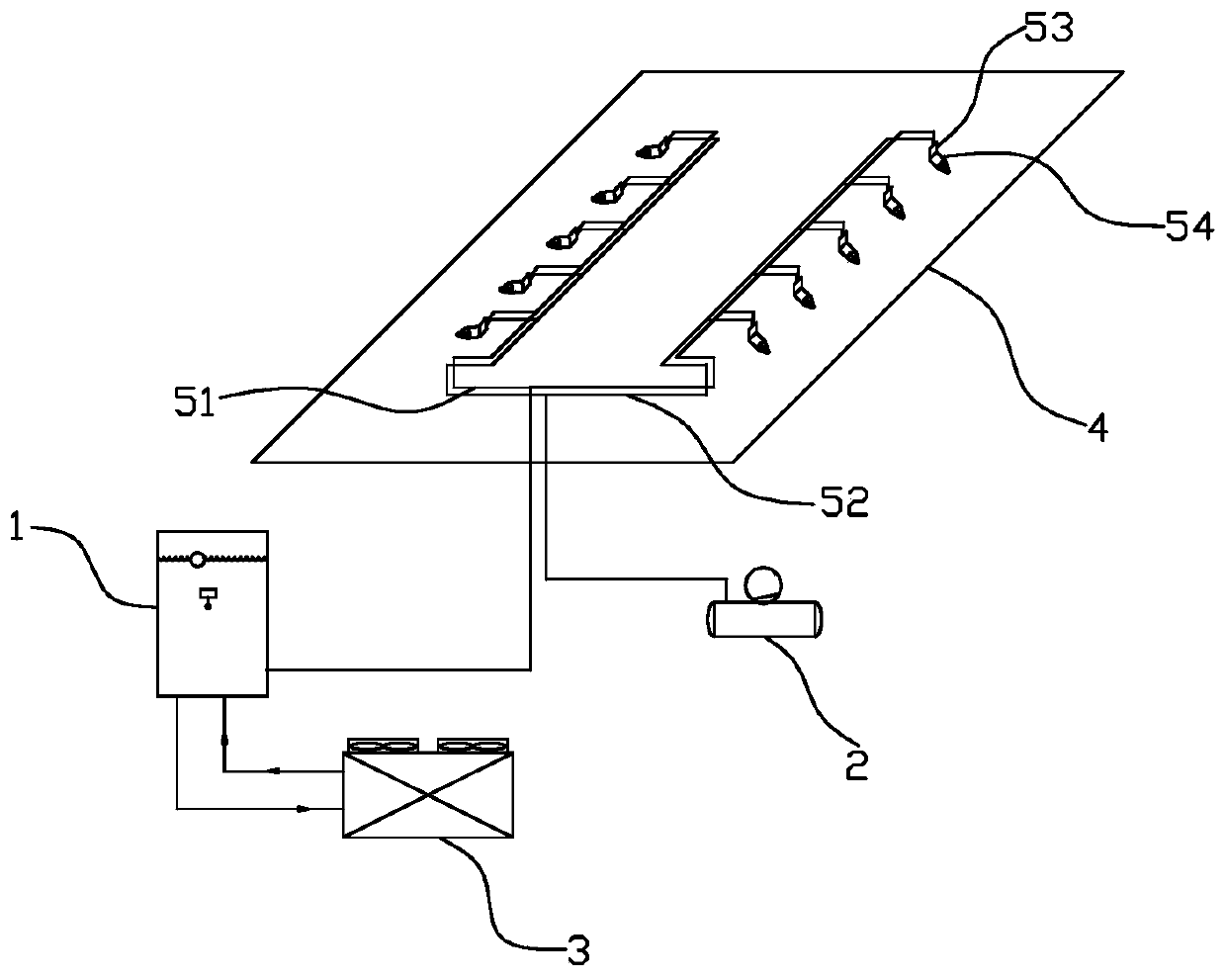

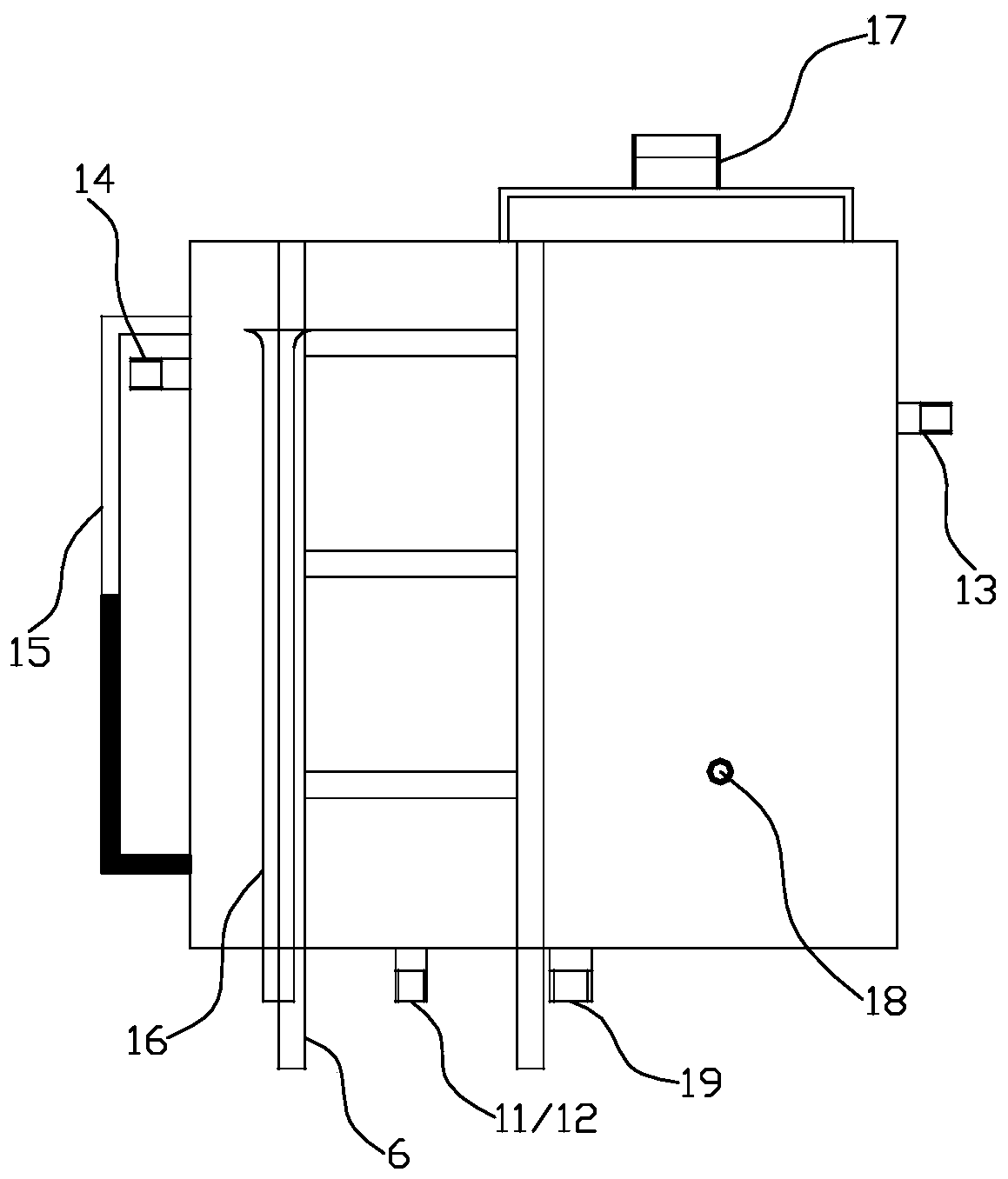

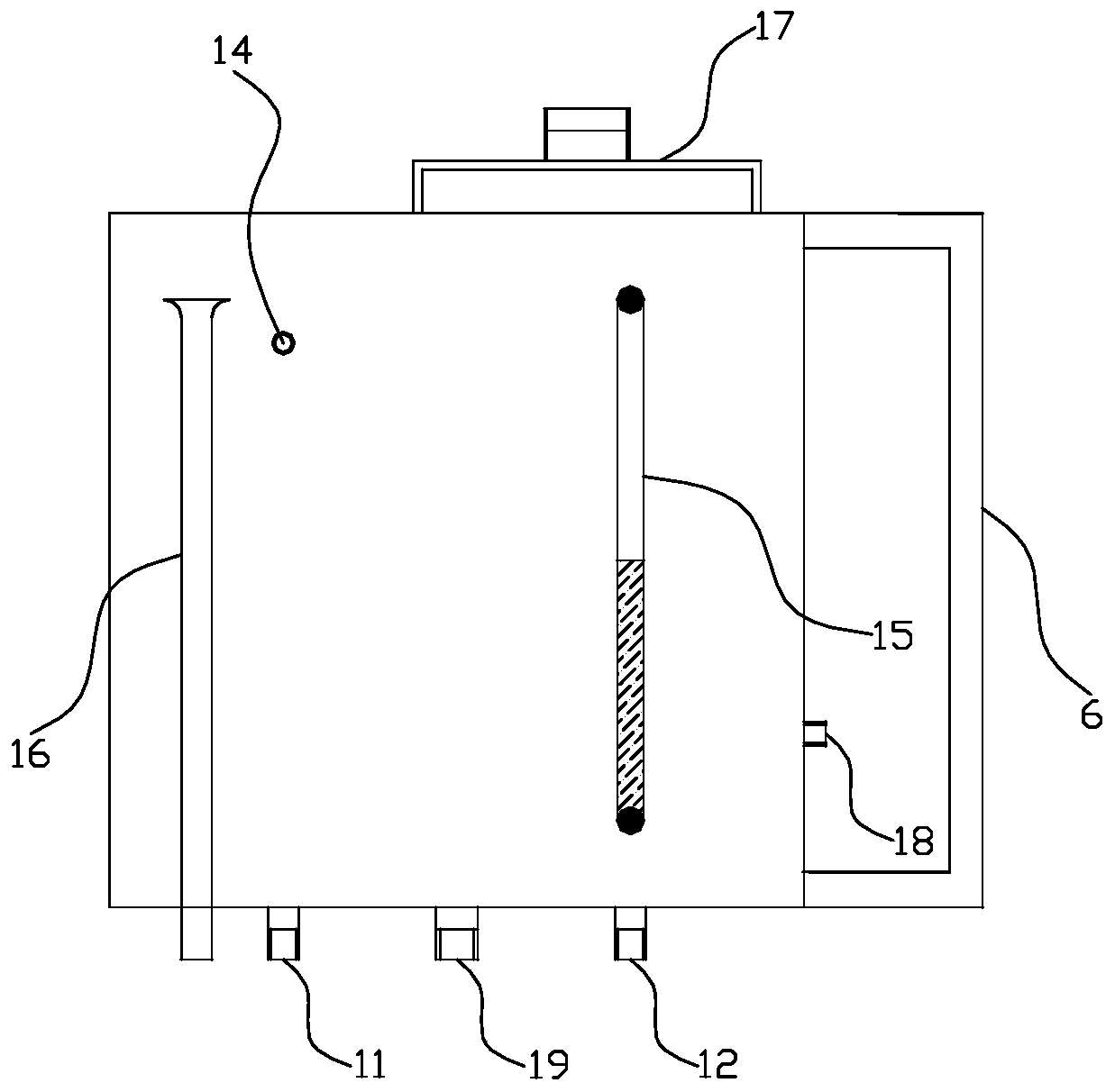

[0034] Such as figure 1As shown, the present invention includes a water vapor mixing ejection unit, a water tank 1 and an air compressor 2 that provides compressed air to the water vapor mixing ejection unit, and is characterized in that: the bottom surface of the water tank 1 is provided with a water outlet 11 and a snowmaking water supply 12, the water tank 1 is provided with a water inlet 13 on the side away from the water outlet 11 and the snowmaking water supply port 12, and the water tank 1 communicates with the air-cooled chiller 3 through the water outlet 11 and the water inlet 13. A water-cooling circulation loop is formed, and the snowmaking water supply port 12 communicates with the water-steam mixing and ejecting unit.

[0035] When the present invention is used for snowmaking in the test room 4: the water tank 1 forms a water cooling cycle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com