Diagonal fan having an optimized housing

A diagonal flow fan and diagonal flow technology, which is applied to liquid fuel engines, components of pumping devices for elastic fluids, axial flow pumps, etc., to achieve the effect of reducing torque and small torque requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

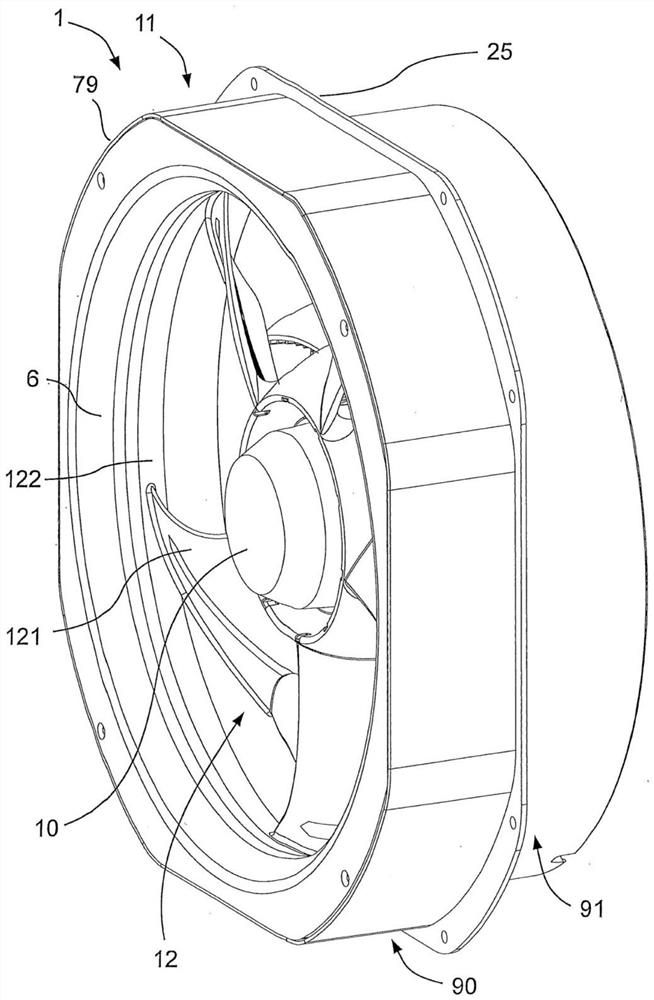

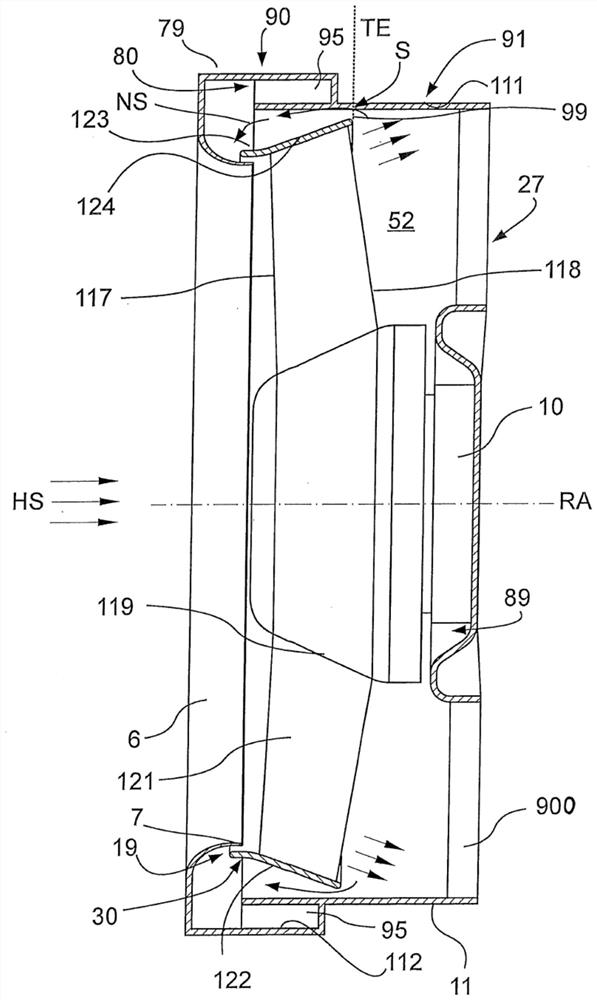

[0028] according to figure 1 with figure 2 The diagonal flow fan 1 comprises a housing 11 in which an electric motor 10 configured as an outer rotor motor is accommodated and is connected to a diagonal flow impeller 12 in order to rotate the latter about an axis of rotation RA during operation. Diagonal flow impeller 12 is fixed on electric motor 10 with its hub 119 . A plurality of rotor blades 121 distributed in the circumferential direction extend radially outward from the hub 119 , and the rotor blades are closed at their radially outer ends by an oil flinger 122 . The impeller blade 121 has a blade front edge 117 and a blade rear edge 118, viewed from the radially inner side to the radially outer side, their distribution is inclined towards the inlet side of the diagonal flow fan 1 relative to the vertical line of the rotation axis , wherein the angle at the rear edge 118 of the blade is greater than the angle at the front edge 117 of the blade.

[0029] On the suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com