Devices and systems for producing silicon

A technology of silicon dioxide, fused silicon, in the field of devices and systems for purifying silicon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

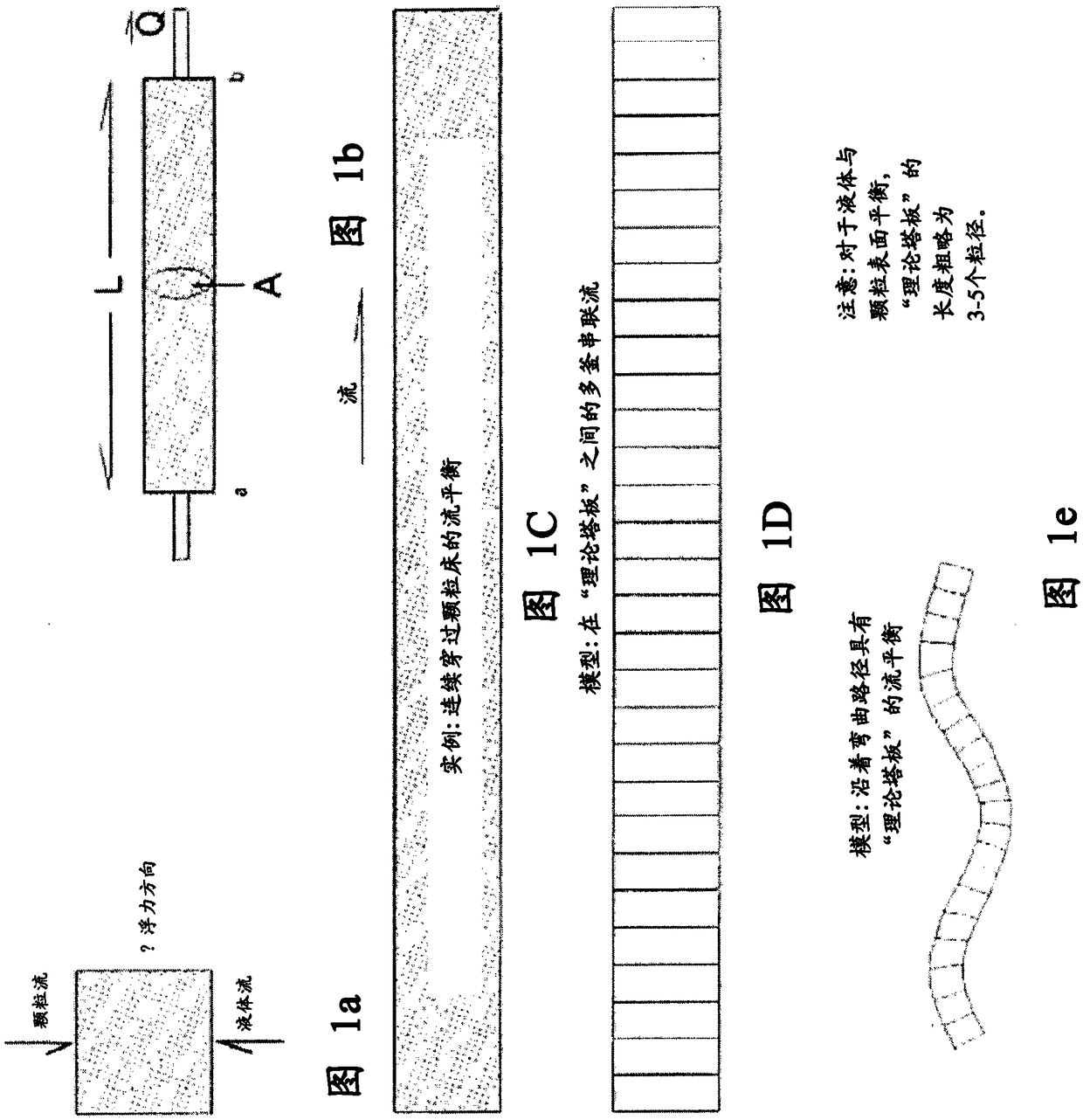

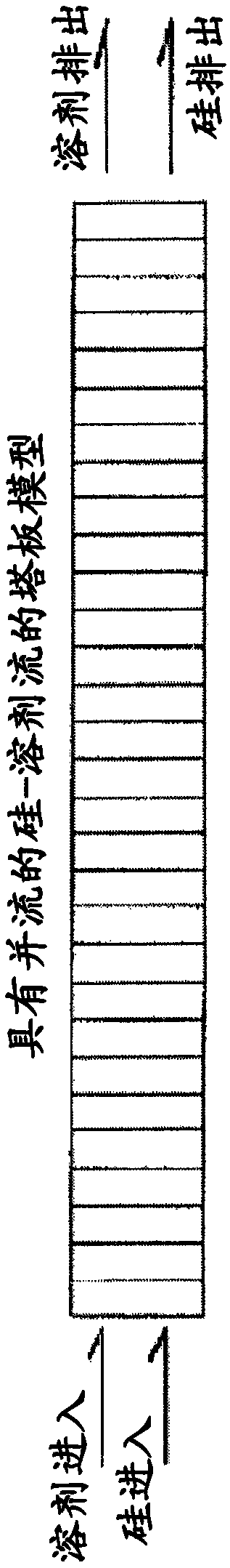

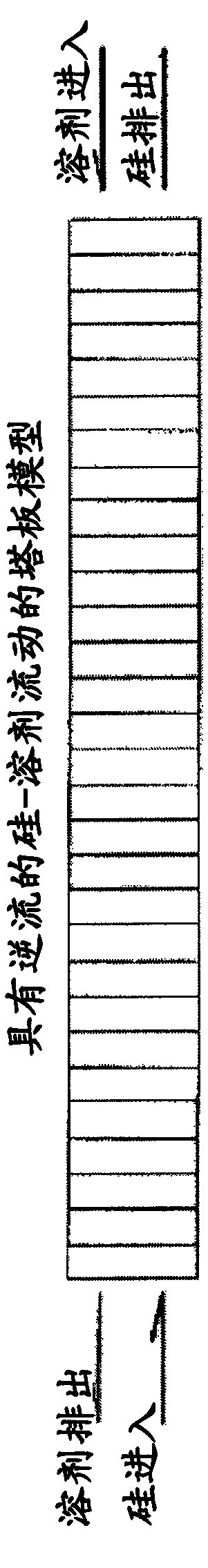

[0059] The present disclosure provides silica purification by a series of co-current and counter-current selective oxidative solvent exchanges over 1414°C. Some embodiments utilize Darcy flow structures similar to those used in packed bed and expanded bed column chromatography. Once the total silicon impurity concentration is low enough, complete purification for most or all impurity elements can be performed with an ordered expanded bed countercurrent purifier using thin-walled silica spheres formed in situ by oxygen bubbling as solvent particles, followed by argon This is accomplished by bubbling to remove dissolved oxygen (and possibly dissolved sulfur) from the molten silicon. The early stages of silica purification can be accomplished in a number of ways. Flowing molten silicon through a packed or expanded bed of silica particles effectively removes most of the impurity species. Selective oxidation of silicide and rapid diffusion of impurity elements through a packed or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com