Ultrasonic detection device used for automobile maintenance

A detection device, ultrasonic technology, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve the problems that it is inconvenient for maintenance personnel to observe the chassis and cannot support automobile chassis, etc. , to achieve the effect of protecting against deviation, saving manpower and material resources, and improving the speed of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

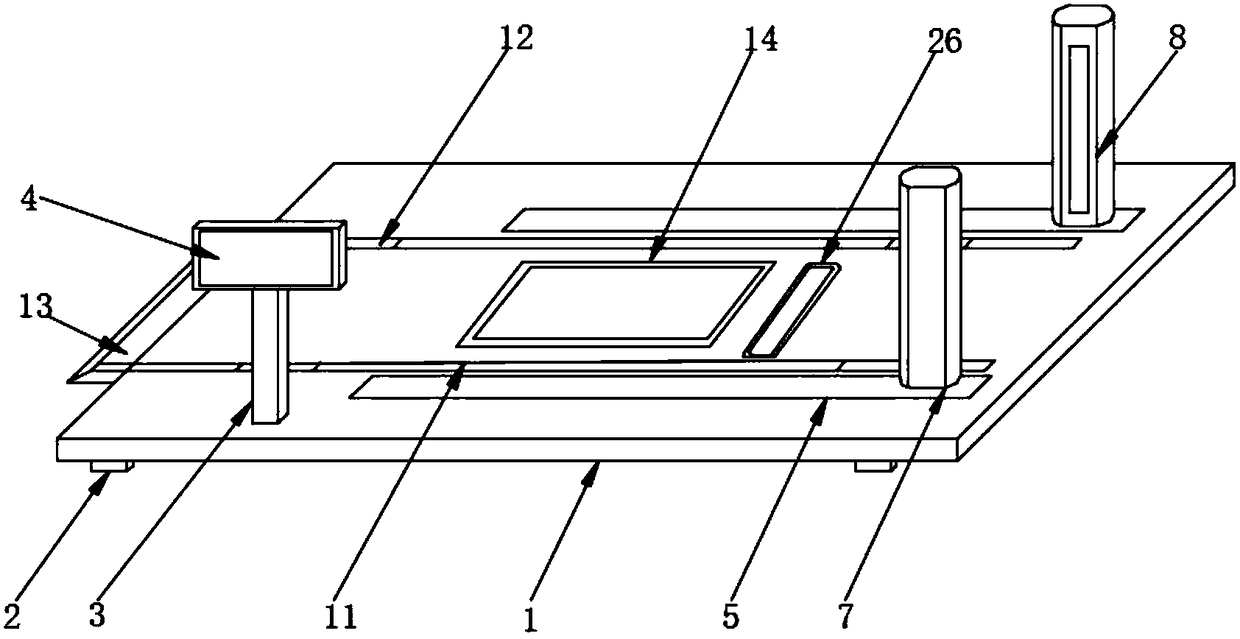

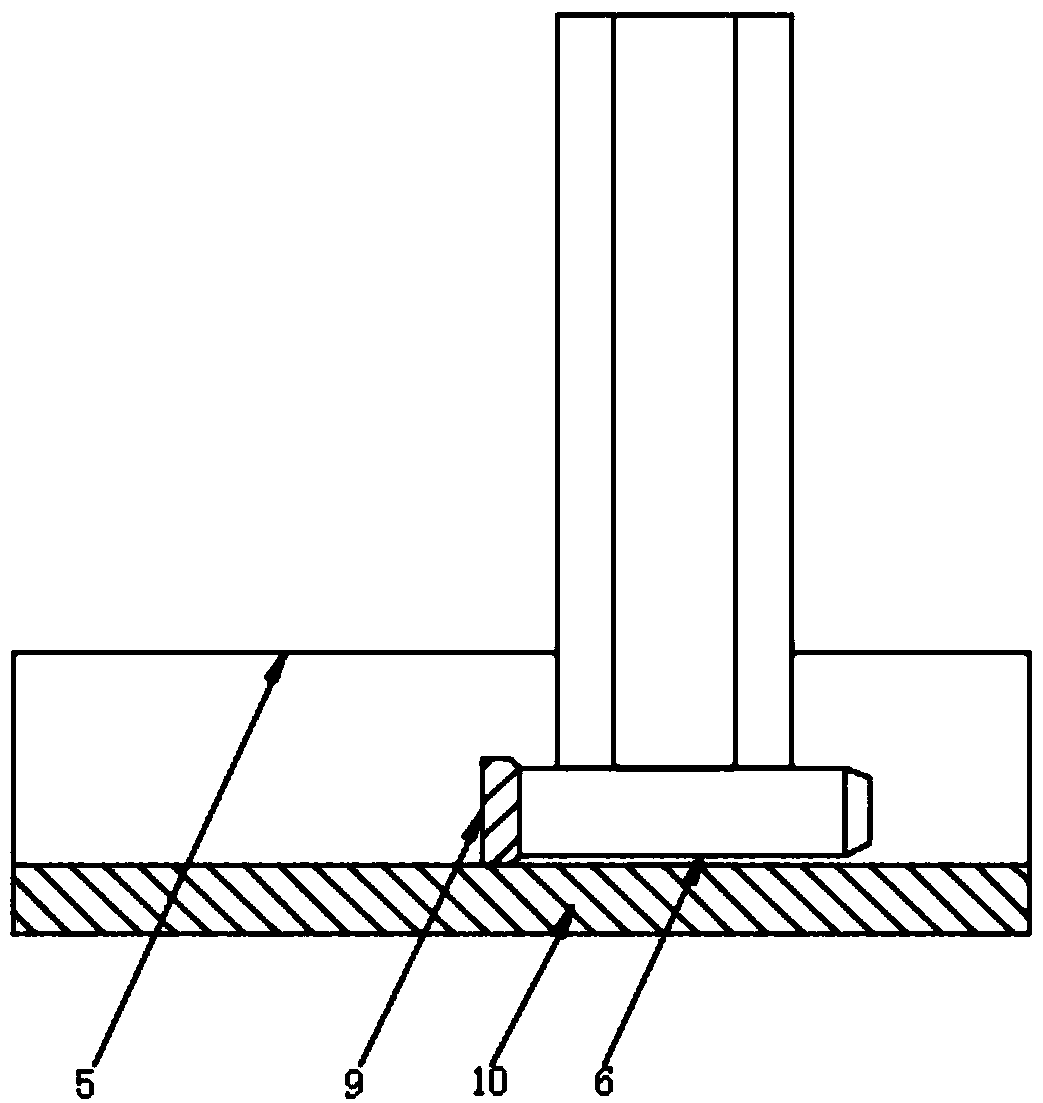

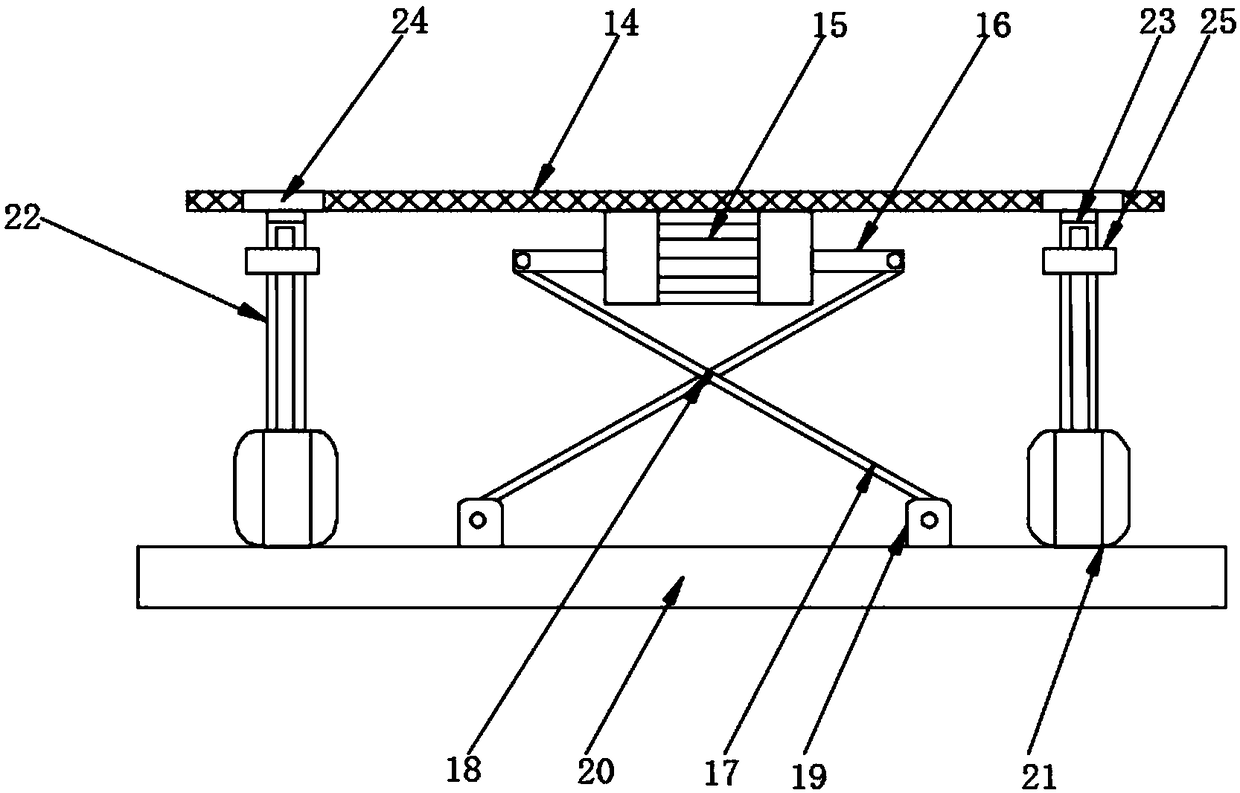

[0028] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, an ultrasonic detection device for automobile maintenance, including a grooved steel plate 1, a pressure measuring device 2, a telescopic rod 3, an operation panel 4, a groove 5, a motor 6, an ultrasonic detector 7, and an anti-interference protection Shell 8, gear 9, gear belt 10, anti-skid belt 11, limit block 12, backing plate 13, support plate 14, two-way hydraulic device 15, hydraulic rod 16, support rod 17, bearing 18, fixed base 19, bearing plate 20. Balance hydraulic device 21, balance hydraulic rod 22, I-beam 23, through hole 24, clamp block 25 and LED light strip 26, pressure measuring device 2 is installed at the four corners of the bottom end of channel steel plate 1, and pressure measuring device 2 includes Support base 201, pressure tester 202, support column 203 and rubber base 204, pressure tester 202 is installed at the bottom of support base 201, support column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com