Balance calibration loading sleeve

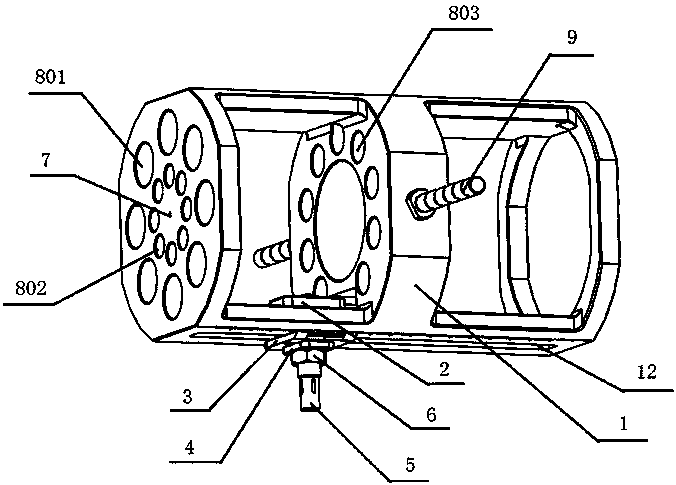

A technology for balance calibration and loading sleeves, which is applied in the direction of measuring devices, instruments, aerodynamic tests, etc., can solve problems such as pitching moment interference, and achieve accurate and firm positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

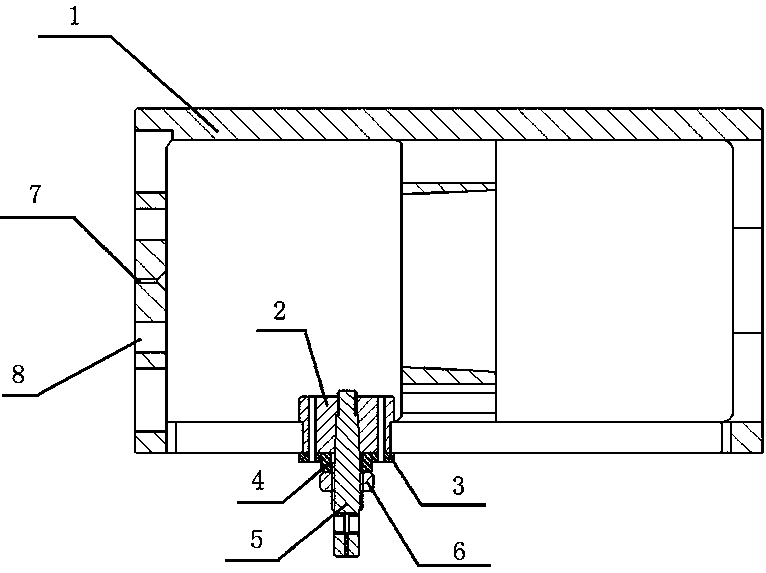

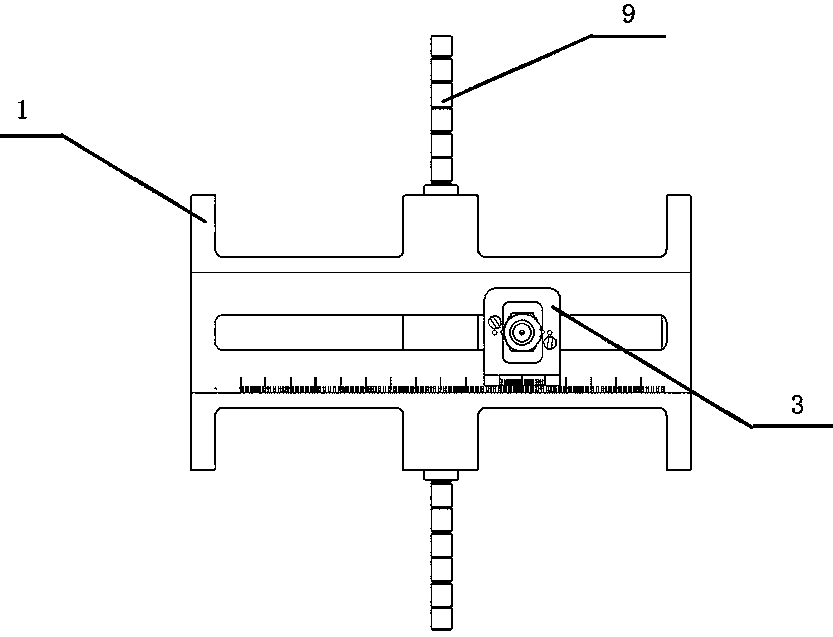

Method used

Image

Examples

Embodiment 1

[0031] When calibrating the piezoelectric balance, first install the piezoelectric balance horizontally on the calibration frame, then install the main body 1 of the loading sleeve on the bearing cone at the front end of the piezoelectric balance through the connecting cone section in the middle, and pass the upper beam of the main body 1 of the loading sleeve The reference plane 11 on the top measures the deflection angle of the installation of the balance calibration loading sleeve, and the loading sleeve main body 1 is fixed after the deflection angle is adjusted to an allowable angle. According to the loading point position determined by the loading table, loosen the compression nut 6, adjust the slider 3 to the corresponding position on the main body 1 of the loading sleeve, and tighten the compression nut 6 to determine the first loading position, the loading line Hang the weights through the holes on the loading pegs 5. Through the cooperative use of the scale on the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com