Flow guiding and flow whirling integrated blade grid type device and combustion chamber

A technology of swirling blades and swirling flow, which is applied in the field of engines to achieve the effects of simple structure, improved circumferential distribution, and avoiding total pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

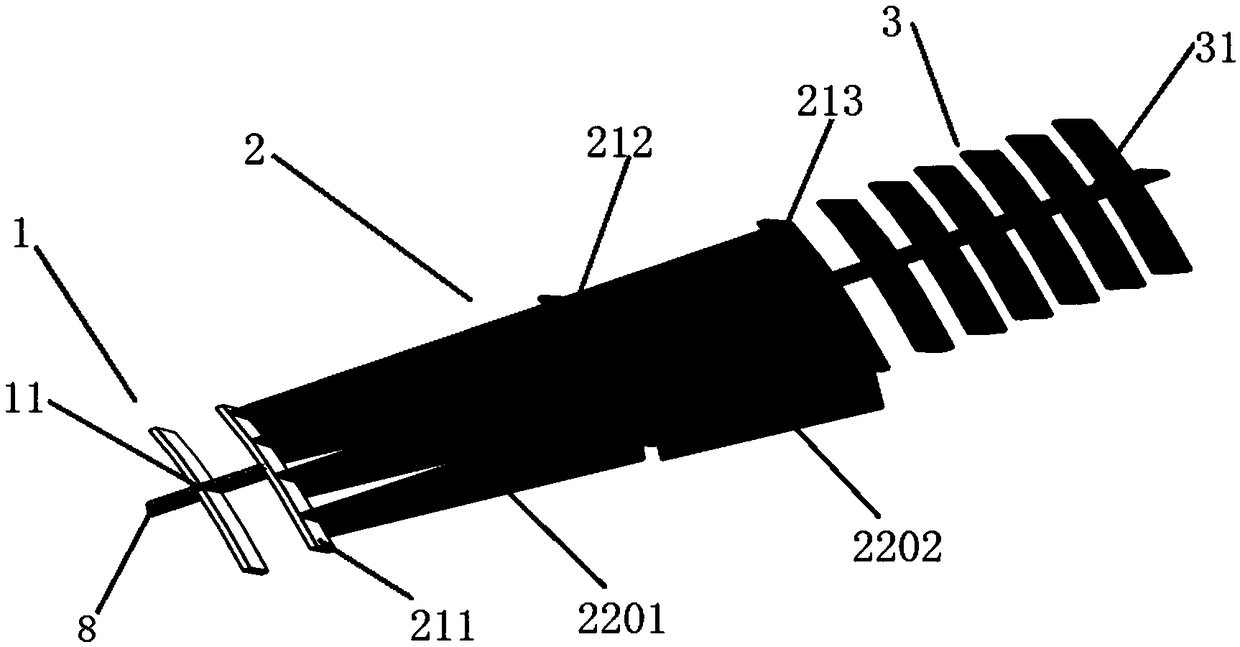

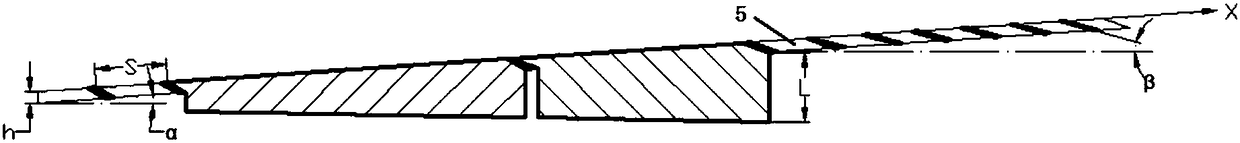

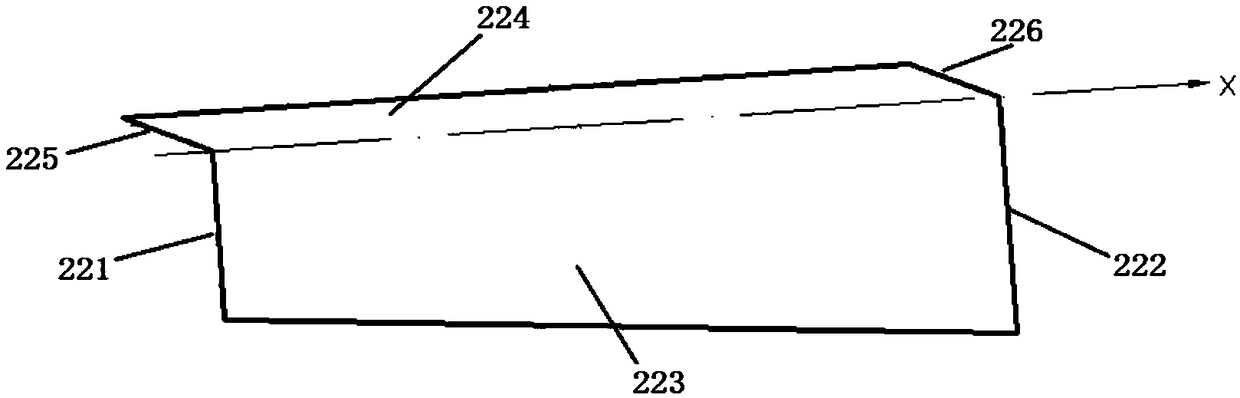

[0026] Such as figure 1 As shown, the integrated cascade device of the present invention, which integrates flow guide and swirl flow, includes a front cascade section 1 connected in sequence, a swirl section 2 for changing the flow direction of the airflow and generating a partial tangential direction, and a rear cascade section 2 The cascade section 3; the front cascade section 1 includes a first conical deflector 11; the rear cascade section 3 includes 6 second conical deflectors 31 coaxially arranged front and rear, the present invention the longitudinal index figure 2 in the X direction. The spacing S between the frustum-shaped deflectors gradually decreases from the first frustum-shaped deflector to the second frustum-shaped deflector, in order to generate different flow resistances to the airflow in the longitudinal direction. In this embodiment , the ratio of the spacing between the frustum-shaped deflectors to the length of the cascade device is reduced from 7% to 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com