Coal mine fully mechanized mining face control robot, system and operation method

A fully-mechanized mining face and robot system technology, applied in the field of coal mine fully-mechanized mining face control robots, can solve the problems of being unable to adapt to the limited space of fully-mechanized mining faces, and achieve improved inspection efficiency and accuracy, safe operating positions, and functional perfect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

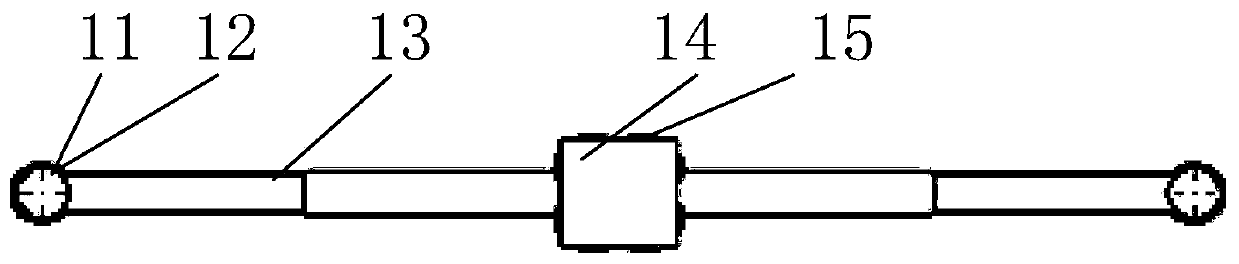

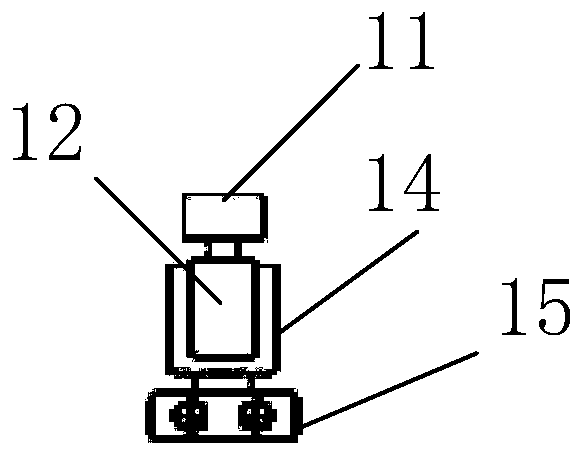

[0031] Such as Figure 1~3 Shown is a schematic structural view of a fully mechanized coal mining face control robot of the present invention, including: a centralized control unit 14, two self-adaptive telescopic arms 13 respectively arranged on both sides of the centralized control unit 14, each of the self-adaptive The front end of the telescopic arm 13 is connected to the centralized control unit 14, the end of each self-adaptive telescopic arm 13 is provided with a swivel joint arm 12, and each swivel joint arm 12 is provided with an adaptive suction device 11;

[0032] The self-adaptive suction device 11 can suck in or disengage from the docking and fixing device arranged on the fully mechanized mining face of the coal mine;

[0033] The end of the self-adaptive telescopic arm 13 is provided with a vertical rotation axis perpen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com