Turning operation guide device for mine hoisting steel wire rope

A technology of guiding device and steel wire rope, which is applied to lifting equipment, transportation and packaging in mines. It can solve the problems of narrow space in the width direction of the lifting container and the inability to effectively play the guiding role of changing ropes, so as to achieve the effect of facilitating the work of changing ropes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

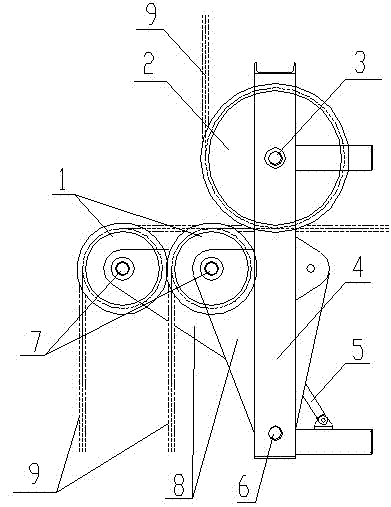

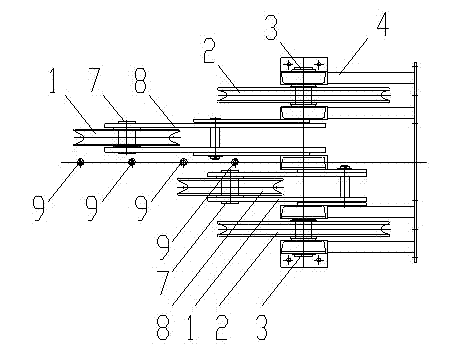

[0010] Such as figure 1 and figure 2 Shown: the present invention comprises movable wheel 1, fixed wheel 2, fixed wheel pin 3, frame 4, hydraulic cylinder 5, movable arm pin 6, movable wheel pin 7 and movable arm 8, and two fixed wheels 2 are fixed by The wheel pin shaft 3 is installed on both sides of the upper part of the frame 4, and the two movable wheels 1 are installed on the front ends of the two movable arms 8 through the movable wheel pin shaft 7, and the movable arm 8 is installed on the bottom of the frame 4 through the movable arm pin shaft 6, and the hydraulic cylinder 5 is connected to movable arm 8.

[0011] The fixed wheel 2 rotates around the fixed wheel pin shaft 3 installed on the frame 4 to guide the hoisting rope 9 with a long moving distance to ensure that the included angle of the rope is small; the movable wheel 1 surrounds the movable wheel insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com