Water permeable brick prepared from basalt tailings and preparation method of water permeable brick

A basalt and permeable brick technology, which is applied in the direction of paving, ceramic products and clay products paved with prefabricated blocks to achieve the effect of good molding, reducing site resources and realizing resource recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment relates to a permeable brick prepared from basalt tailings,

[0029] The total weight of the surface layer raw materials is 300g, including 270g of basalt tailings powder with a particle size of 20-40 mesh, 15g of molecular sieve waste, and 15g of clay.

[0030] The total weight of raw materials for the bottom layer is 2000g, including 1500g of basalt tailings powder with a particle size of 5-20 mesh, 300g of basalt tailings powder with a particle size of 20-40 mesh, 100g of molecular sieve waste, and 100g of clay.

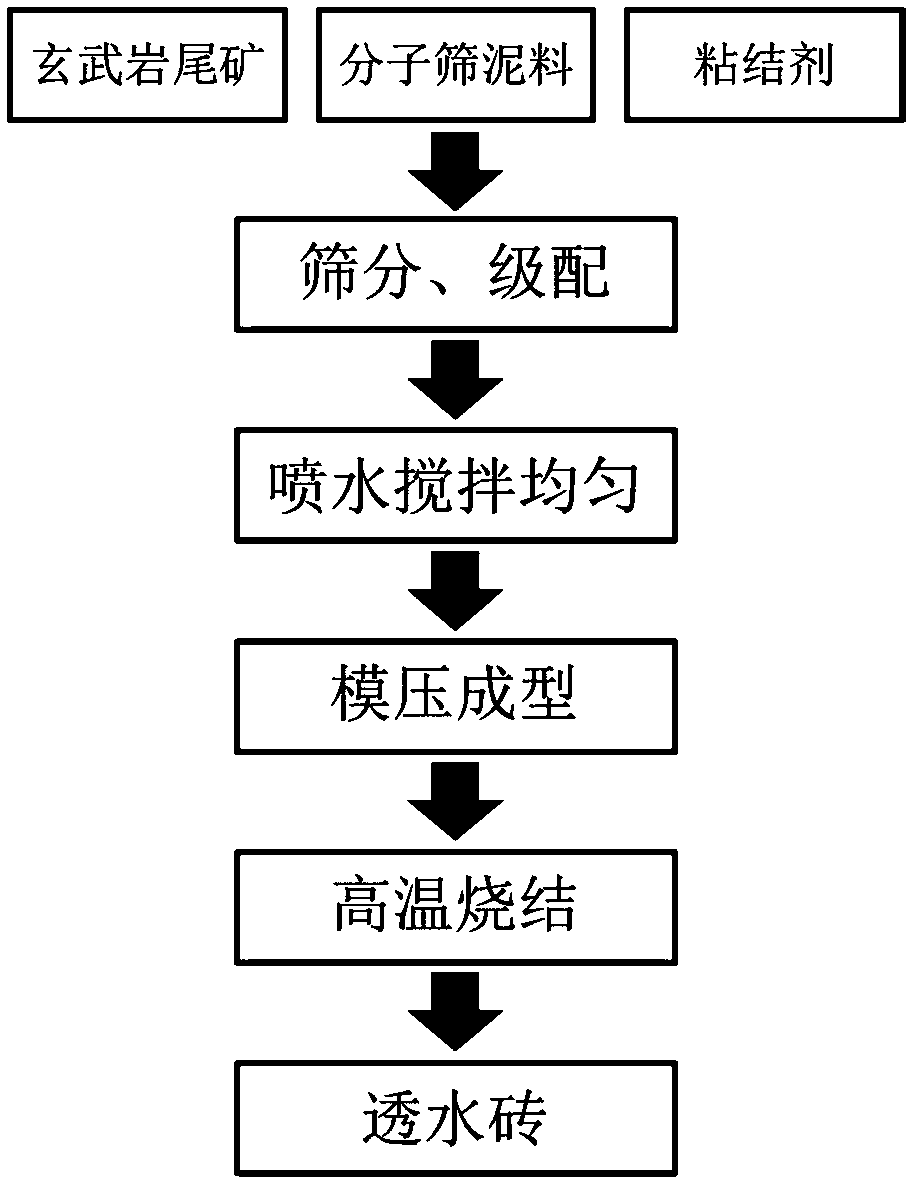

[0031] This embodiment also relates to the preparation method of the above-mentioned permeable brick (see figure 1 ), including the following steps:

[0032] 1) Mix the surface layer raw materials and the bottom layer raw materials separately, spray water and stir them evenly; put the two layers of raw materials that have been mixed separately into the mold in order, and mold them for 40 seconds under the pressure of 800KN, and form them to...

Embodiment 2

[0036] This embodiment relates to a permeable brick prepared from basalt tailings,

[0037] The total weight of the surface layer raw materials is 300g, including 270g of basalt tailings powder with a particle size of 20-40 meshes, 9g of molecular sieve waste, and 21g of clay.

[0038] The total weight of raw materials for the bottom layer is 2000g, including 1400g of basalt tailings powder with a particle size of 5-20 mesh, 400g of basalt tailings powder with a particle size of 20-40 mesh, 60g of molecular sieve waste, and 140g of clay.

[0039] This embodiment also relates to the preparation method of the above-mentioned permeable brick, comprising the following steps:

[0040] 1) Mix the surface layer raw materials and the bottom layer raw materials respectively, spray water and stir them evenly; put the mixed two layers of raw materials into the mold respectively, and mold them for 40 seconds under the pressure of 800KN, and form them to obtain a green body;

[0041] 2) P...

Embodiment 3

[0044] This embodiment relates to a permeable brick prepared from basalt tailings,

[0045] The total weight of the surface layer raw materials is 300g, including 270g of basalt tailings powder with a particle size of 20-40 mesh, 21g of molecular sieve waste, and 9g of clay.

[0046] The total weight of raw materials for the bottom layer is 2000g, including 1600g of basalt tailings powder with a particle size of 5-20 mesh, 200g of basalt tailings powder with a particle size of 20-40 mesh, 140g of molecular sieve waste, and 60g of clay.

[0047] This embodiment also relates to the preparation method of the above-mentioned permeable brick, comprising the following steps:

[0048] 1) Mix the surface layer raw materials and the bottom layer raw materials respectively, spray water and stir them evenly; put the mixed two layers of raw materials into the mold respectively, and mold them for 40 seconds under the pressure of 800KN, and form them to obtain a green body;

[0049] 2) Put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com