Welding tool of boiler eccentric furnace pipe

A technology of welding tooling and eccentric furnace, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems such as difficulty in realizing synchronous rotation of front tube sheet 1 and rear tube sheet 2, and difficulty in guaranteeing welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

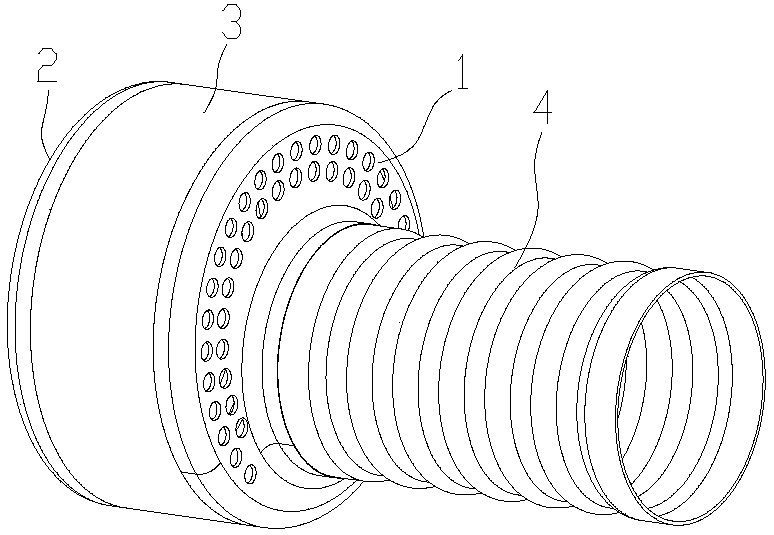

[0013] like figure 1 , 2 As shown, during the welding process of the boiler, it is usually necessary to weld the front tube sheet 1 with an eccentric opening relative to the center of the circular tube sheet and one end of the furnace 4 by welding, and then connect the front and rear tube sheets 1 and 2 with The re-combustion chamber barrel 3 is welded to form the first-stage assembly of the re-combustion chamber furnace. The present invention is to ensure the quality of the welding seam between the front and rear tube sheets 1 and 2 and the cylinder body 3 of the combustion chamber.

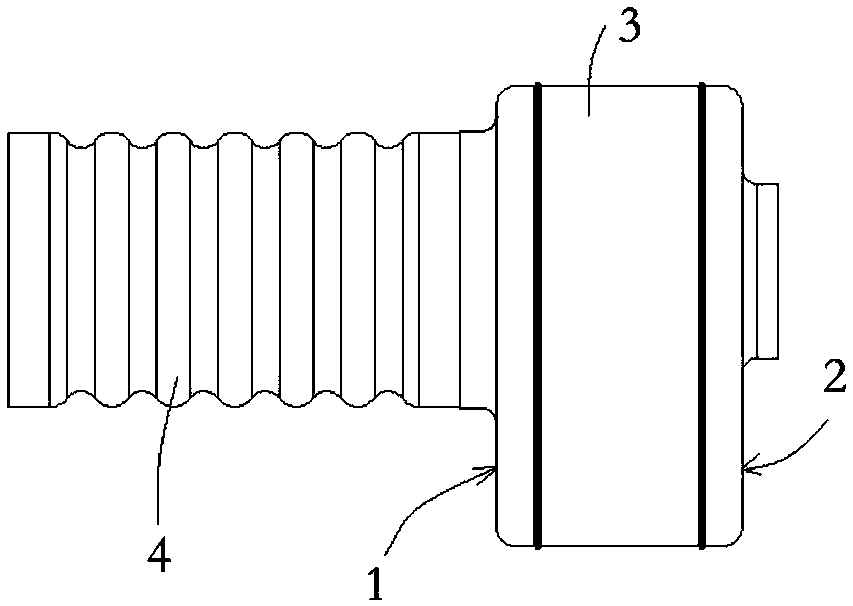

[0014] like image 3 , 4 As shown, the welding tool of the boiler eccentric furnace includes a sleeve 10 sleeved on the furnace 4, the sleeve 10 is provided with a bracket 20 extending to the inside of the tube cavity, and the suspended end of the bracket 20 is connected with the furnace 4, The furnace 4 and the sleeve 10 are eccentrically arranged, and the sleeve 10 is arranged in the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com