Wheel, rim rotary rolling process and rotary rolling device

A rim and rolling technology, applied in the direction of rims, forming tools, manufacturing tools, etc., can solve the problems of rim thickness and weight, rim material hardness and low structural strength, and achieve the effect of reducing weight, light weight and improving surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

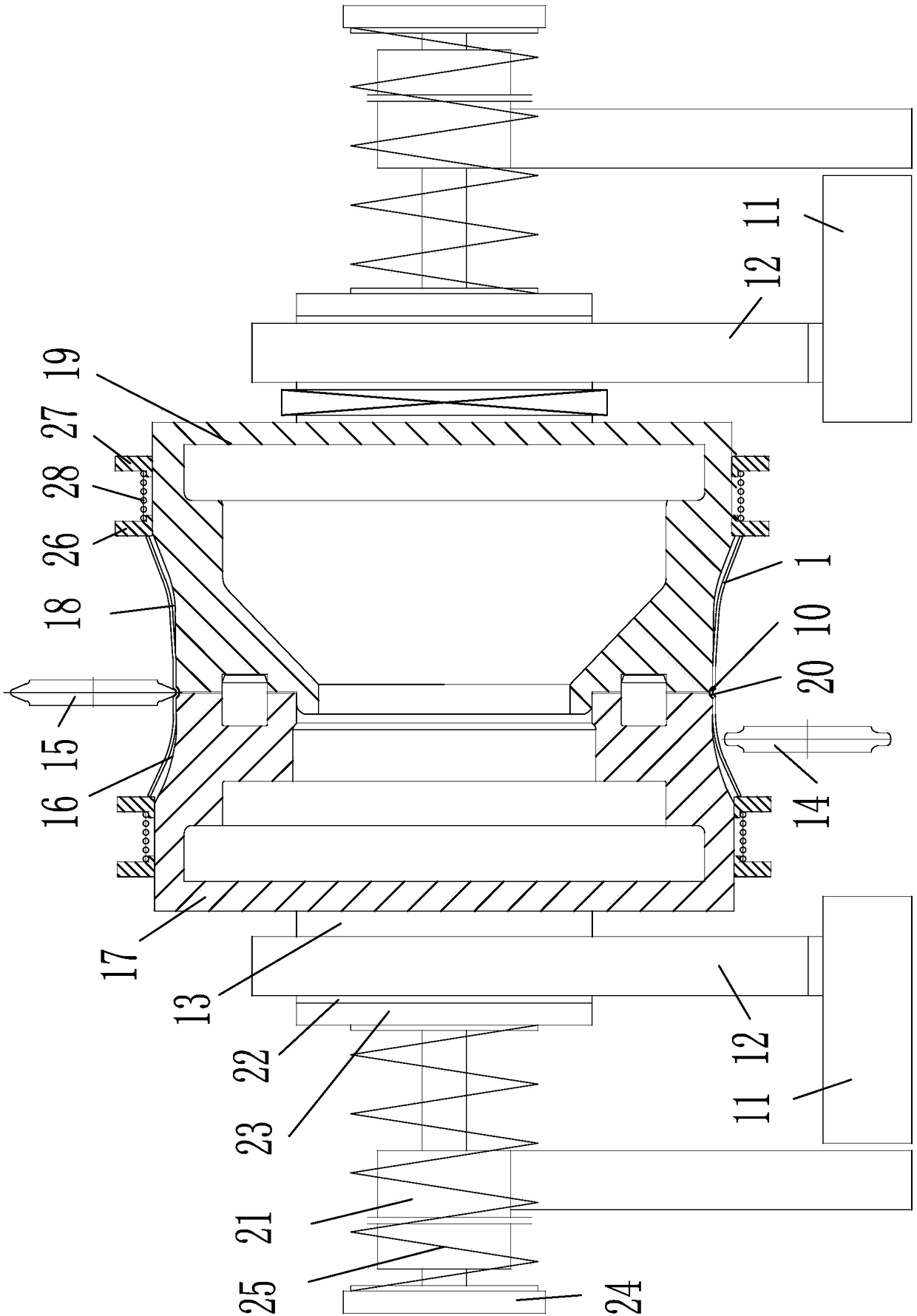

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

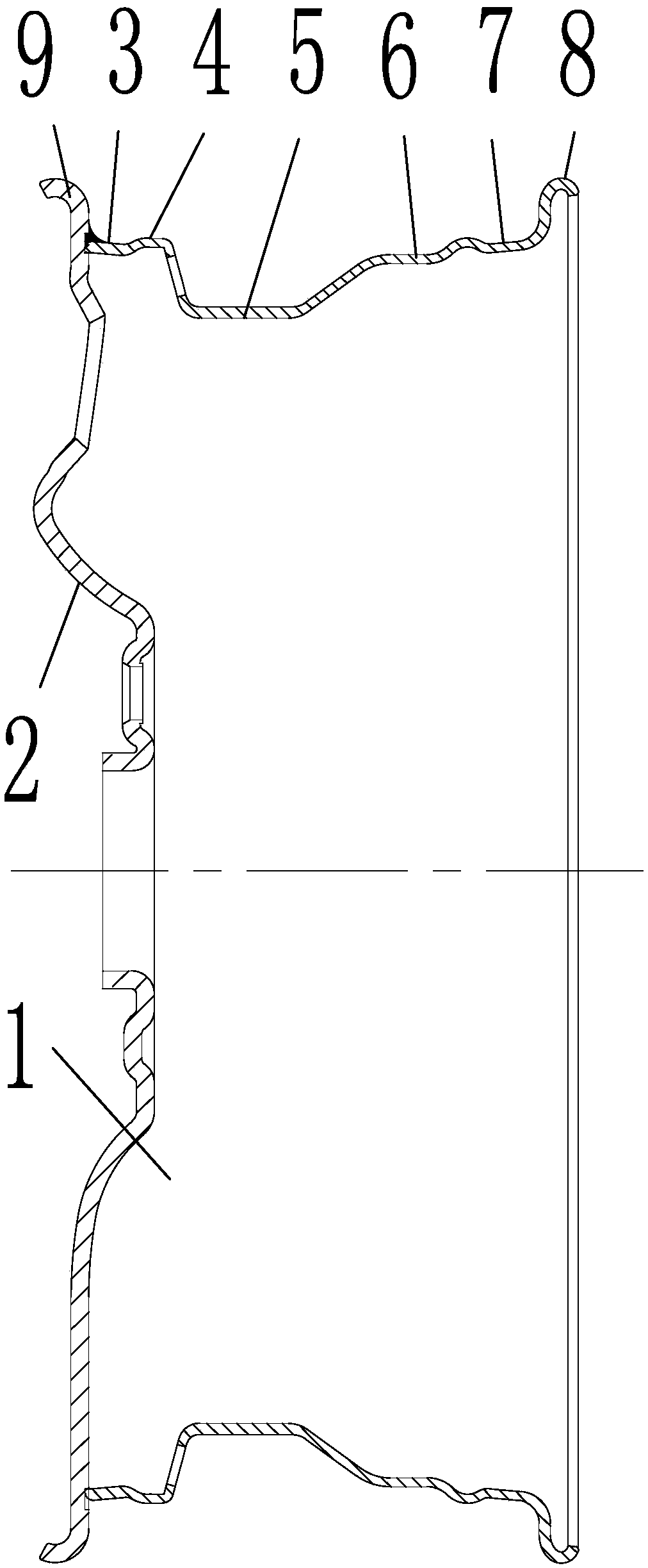

[0016] as attached figure 1 Shown: a wheel, including: a rim 1 and a spoke 2; the rim 1 includes: an outer bead seat 3, a first spinning section 4, a bottom groove 5, a second spinning section 6 and The inner rim 8; the second spinning section 6 is provided with an inner bead seat 7 connected to the inner rim 8; the thicknesses of the first spinning section 4 and the second spinning section 6 are respectively smaller than the outer bead seat 3 and the bottom groove 5 and the thickness of the inner rim 8; the connecting end of the outer bead seat 3 and the first spinning segment 4, the connecting end of the bottom groove 5 and the first spinning segment 4, the connecting end of the bottom groove 5 and the second spinning segment 6 1. The connection ends between the inner rim 8 and the inner bead seat 7 are provided with fillet transitions with gradually thinning thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com