Preparation for high-efficiency ultrafine TiO2 nanoparticle/graphite phase carbon nitride nanosheet composite photocatalyst

A graphite-phase carbon nitride and composite catalyst technology, which is applied in the field of photocatalytic materials, can solve the problems of not being able to fully utilize sunlight and achieve high-efficiency photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment 1

[0026] TiO 2 The preparation method of nanorod / graphitic carbon nitride nanosheet composite catalyst:

[0027] 1. Dissolve 2 ml of 15-20% TiCl 3 aqueous solution and 1 mL of 0.5M SnCl 4 The aqueous solution was added to 60 ml of ethanol, and 90 mg of carbon nitride nanosheets were added to the above solution, ultrasonically dispersed for 30 minutes, then the above solution was transferred to a 100 ml hydrothermal reaction kettle, and placed in a blast oven The temperature was raised to 100° C. and maintained at 100° C. for 4 hours, and then cooled naturally.

[0028] 2. Put the dispersion obtained in step 1 in a centrifuge tube, and remove the supernatant by centrifugation to obtain a solid.

[0029] 3. Add 10 ml of ethanol solution to the solid obtained in step 2, sonicate until completely dispersed, and unreacted TiCl 3 Removal, followed by centrifugation, yielded a solid.

[0030] 4. Dry the solid obtained in step 3 in an oven at 70°C, and dry in the oven to obtain TiO...

Embodiment 2

[0032] Example 2TiO 2 Preparation method of nanoparticle / graphite phase carbon nitride nanosheet composite catalyst:

[0033] 1. Add 2 ml of 15-20wt% TiCl 3 The aqueous solution was added to 60 mL of ethanol and stirred at room temperature for 30 minutes. Then the above solution was transferred to a 100 ml hydrothermal reaction kettle, which was placed in a blast oven and heated to 100° C. and kept at 100° C. for 6 hours, and cooled naturally.

[0034] 2. Put the dispersion obtained in step 1 in a centrifuge tube, and remove the supernatant by centrifugation to obtain a solid.

[0035] 3. Add 10 ml of ethanol solution to the solid obtained in step 2, sonicate until completely dispersed, and unreacted TiCl 3 Removal, followed by centrifugation, yielded a solid.

[0036] 4. Dry the solid obtained in step 3 in an oven at 70°C to obtain TiO 2 The nanoparticle / graphite phase carbon nitride nanosheet composite catalyst powder is about 200 mg.

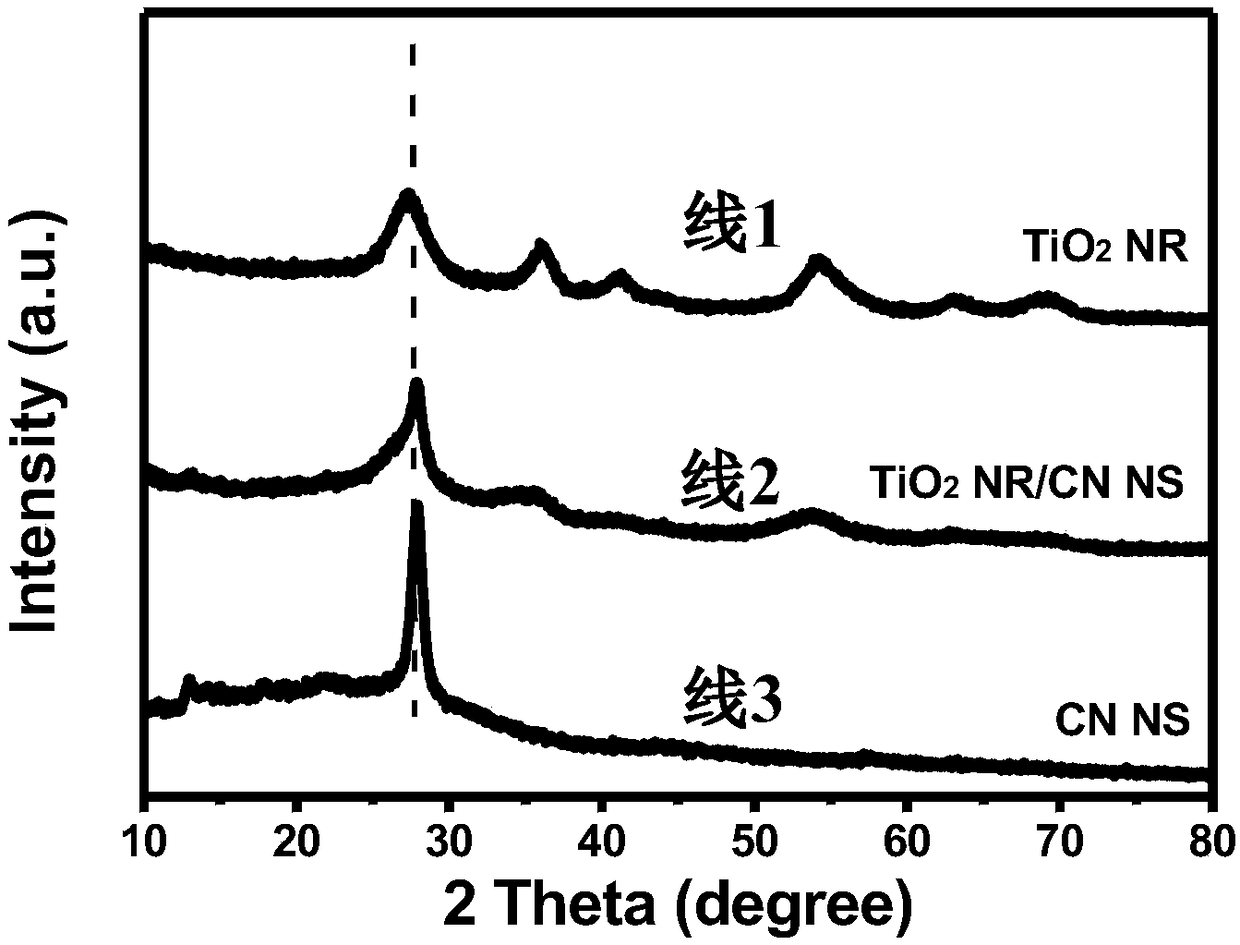

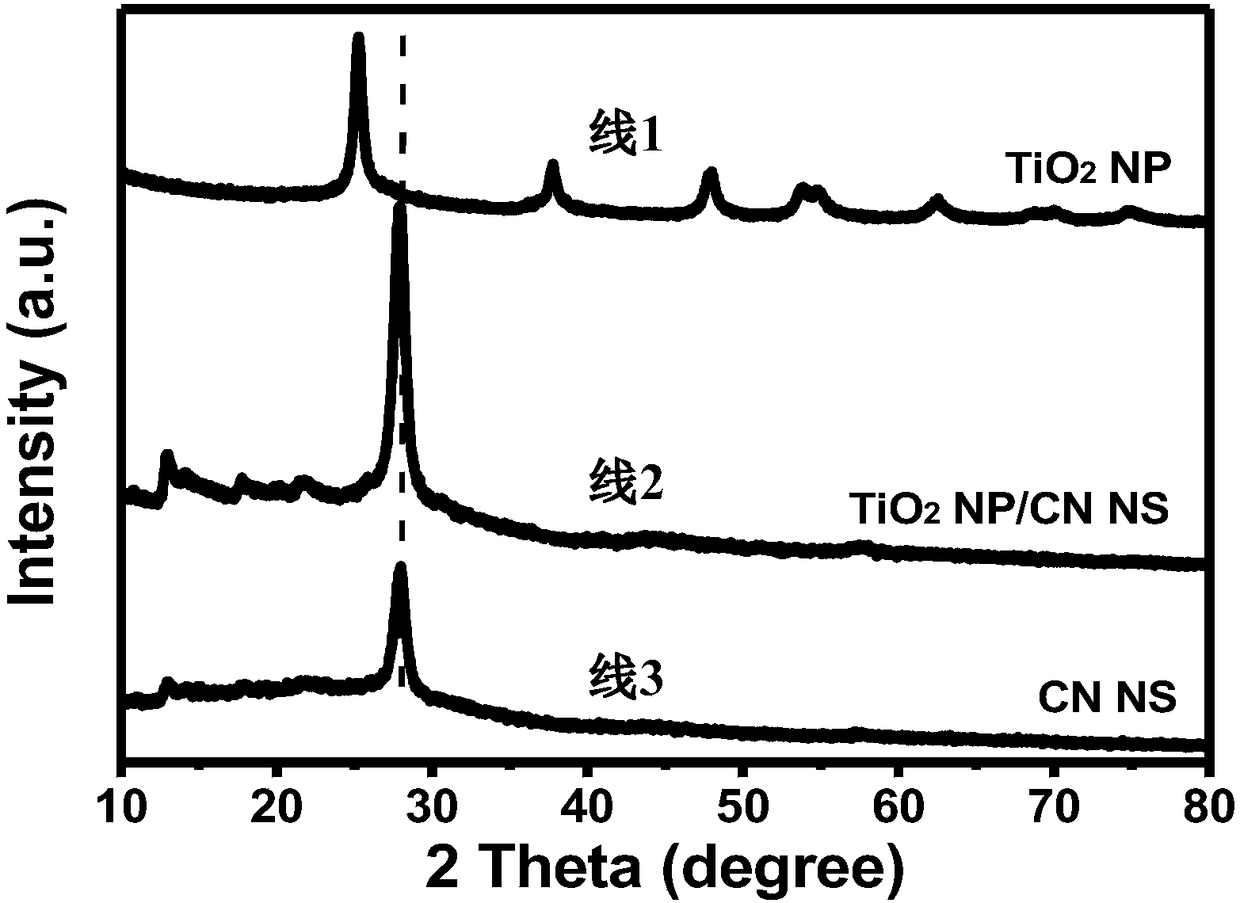

[0037] image 3 Line 1 in is to...

Embodiment 3

[0039] TiO 2 Preparation method of nanorod / graphite phase carbon nitride nanosheet composite catalyst

[0040] 1. Add 4 ml of 15-20% TiCl 3 aqueous solution and 2 ml of 0.5M SnCl 4 The aqueous solution was added to 60 ml of ethanol, and 120 mg of carbon nitride nanosheets were added to the above solution, ultrasonically dispersed for 30 minutes, then the above solution was transferred to a 100 ml hydrothermal reaction kettle, and placed in a blast oven The temperature was raised to 100° C. and maintained at 100° C. for 4 hours, and then cooled naturally. .

[0041] 2. Put the dispersion obtained in step 1 in a centrifuge tube, and remove the supernatant by centrifugation to obtain a solid.

[0042] 3. Add 10 ml of ethanol solution to the solid obtained in step 2, sonicate until completely dispersed, and unreacted TiCl 3 Removal, followed by centrifugation, yielded a solid.

[0043] 4. Dry the solid obtained in step 3 in an oven at 70°C, and dry in the oven to obtain TiO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com