A red light responsive shape memory polymer material and preparation method thereof

A technology of polymer materials and memory materials, applied in the field of functional materials, can solve the problems of poor biocompatibility and biodegradability, and achieve the effect of shape recovery and strong penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1. Preparation and use of shape memory polymer with infrared light responsiveness

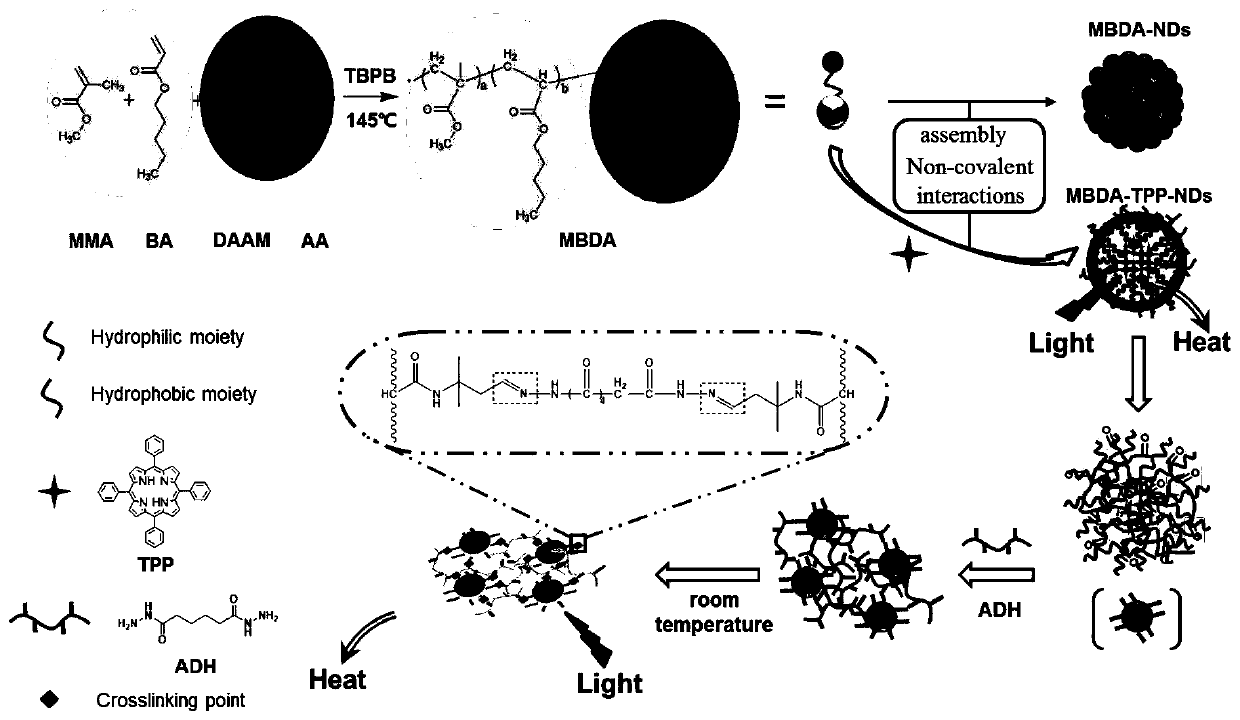

[0049] Such as figure 1 Shown is a schematic diagram of preparing a shape memory polymer containing infrared light-responsive porphyrin.

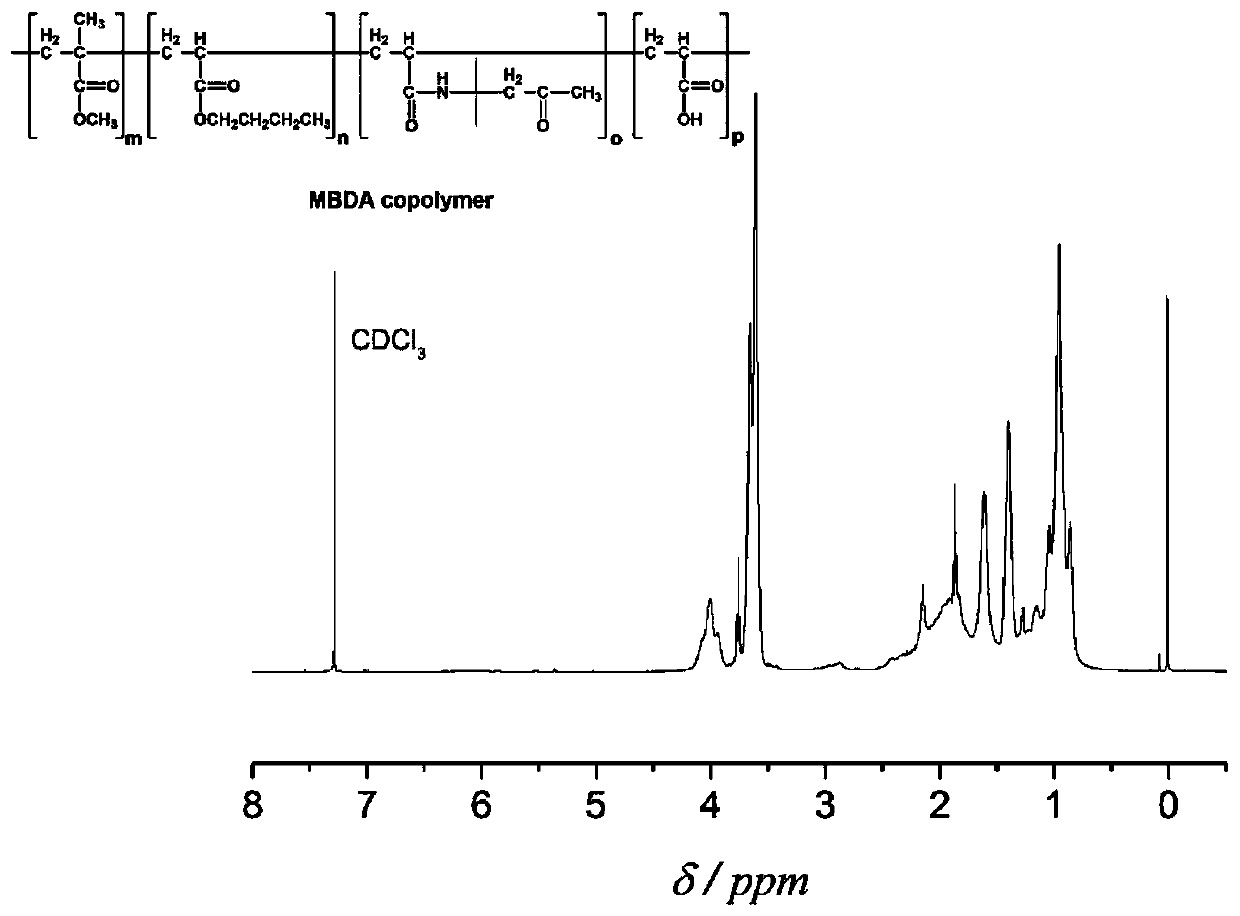

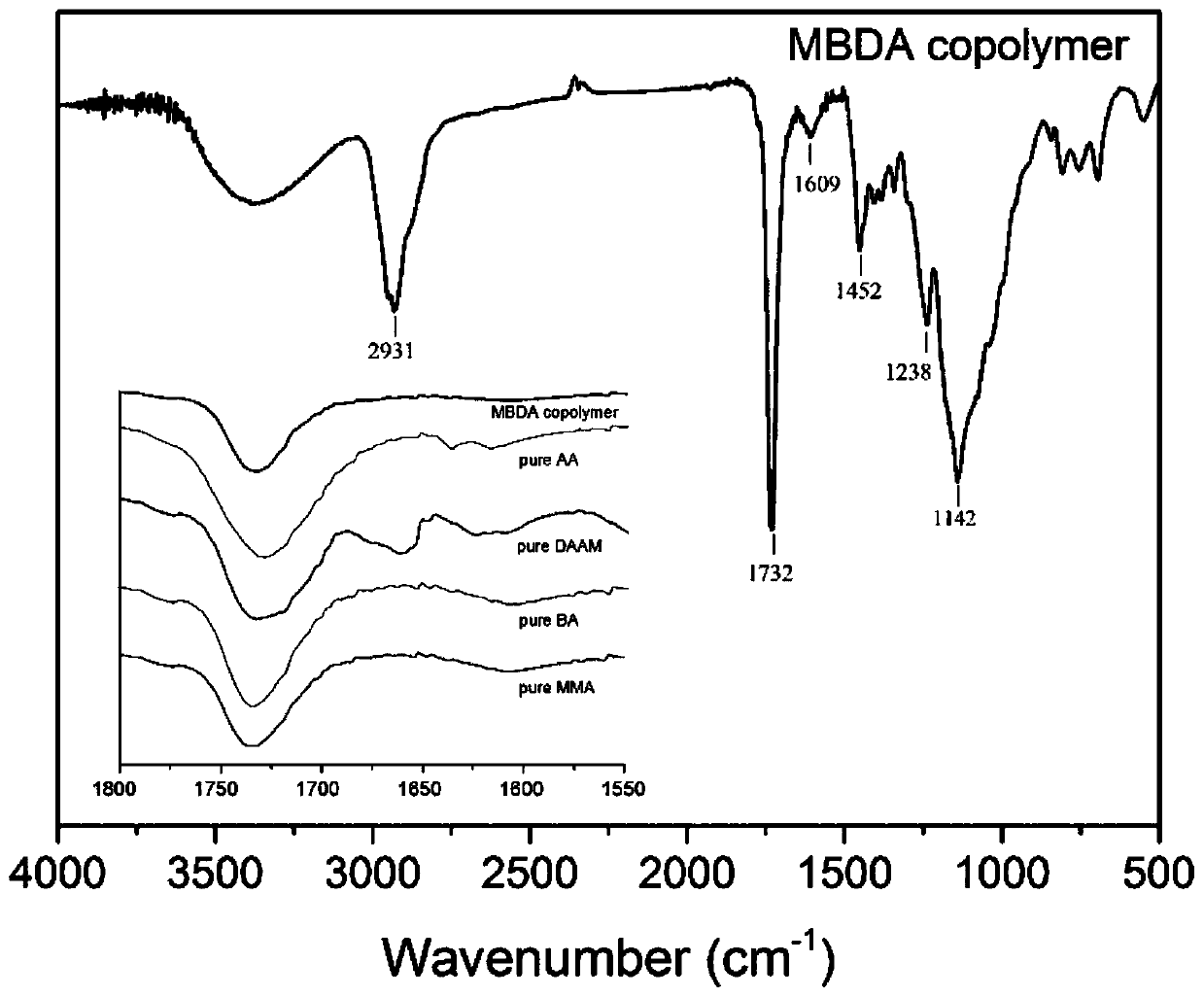

[0050] (1) Solvent ethylene glycol butyl ether 10mL; 30.06g of vinyl monomers containing hydrophobic groups include: 20.77g of methyl methacrylate (MMA) and 9.29g of butyl acrylate (BA); containing hydrophobic groups A total of 1.05g of vinyl monomers include: acrylic acid (AA) 1.05g; a total of 2g of vinyl monomers containing reactive groups include: diacetone acrylamide (DAAM) 2g; free radical initiator tertiary benzoic acid Butyl ester (TBPB) 0.84g. After reacting at 140°C for 3 hours, adding 20 mL of solvent to dilute, the product was purified by ether precipitation three times, and vacuum dried to obtain the amphiphilic polymer MBDA.

[0051] (2) Take 1.6858g of amphiphilic polymer MBDA and a certain amount (0, 0.5mg, 1.5mg, 5mg) of porphyrin (TPP), a...

Embodiment 2

[0070] Solvent dimethyl sulfoxide 10mL, monomer methyl acrylate 0.32mol, ethyl methacrylate 0.08mol, N-vinylpyrrolidone 0.016mol, methacrylic acid 0.016mol, initiator tert-butyl peroxybenzoate 0.08mol, After reacting at 140°C for 3 hours, adding 20 mL of solvent to dilute, the product was purified by ether precipitation three times, and dried under vacuum to obtain an amphiphilic polymer. Take 4g of amphiphilic polymer and 3mg of porphyrin, add 10mL of THF to disperse and dissolve completely, add alcoholamine dropwise to adjust the pH to alkalescence, then slowly add dropwise 10mL of deionized water, after the completion of the addition, evaporate THF at a constant temperature of 50℃ to prepare Encapsulate porphyrin micelles. The micellar solution is added with the crosslinking agent glutaraldehyde with a molar ratio of 1:1 to the N-vinylpyrrolidone, and dried and cured at room temperature to form a film.

[0071] The prepared membrane material is deformed in an environment of 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com