Novel electric axle assembly

An electric vehicle and assembly technology, applied in axles, wheels, vehicle parts, etc., can solve the problem of not being able to maximize the space for lightweight battery layout of the electric vehicle powertrain, increase the energy consumption per unit load of electric vehicles, and reduce the vehicle load. Chassis space utilization and other issues to achieve the effect of increasing passenger capacity and cruising range, significant production practice significance, and shortening the length of the transmission chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

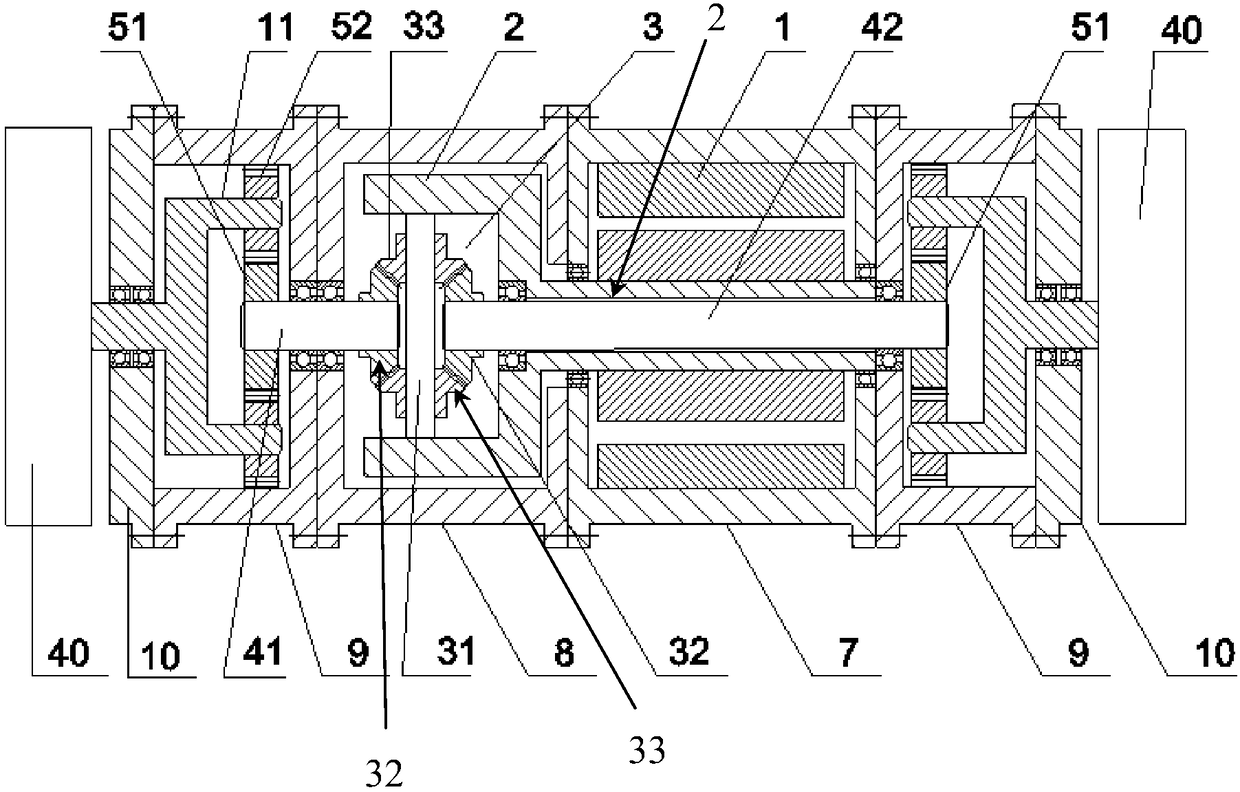

[0034] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

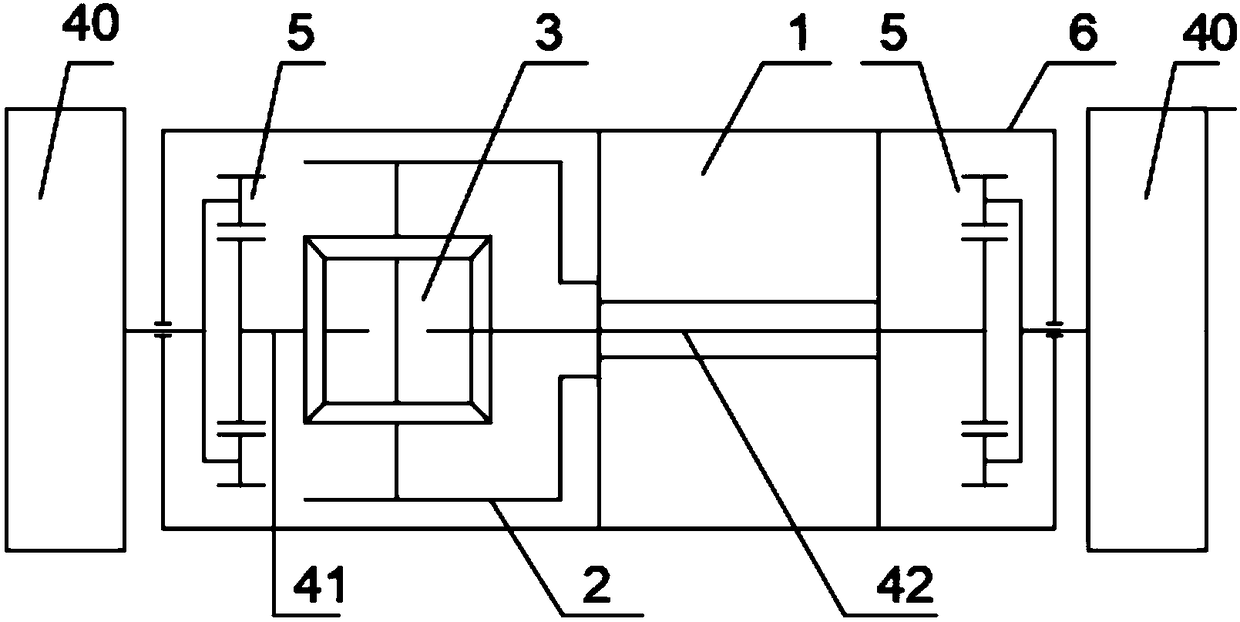

[0035] see figure 1 , figure 2 , the present invention provides a novel electric axle assembly, comprising a drive motor 1 placed horizontally and a hollow motor power output shaft 2;

[0036] The left end of the motor power output shaft 2 protrudes from the left side wall of the drive motor 1, and the right end of the motor power output shaft 2 is arranged inside the drive motor 1;

[0037] The inside of the left end of the motor power output shaft 2 is fixedly connected with the differential 3, specifically: the inside of the left end of the motor power output shaft 2 is fixedly connected with the power input shaft of the differential 3;

[0038] The power output ends on the left and right sides of the differential are respectively conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com