Multi-groove pot used for tea making and tea making method thereof

A technology for multi-slot pots and tea, which is applied in tea treatment before extraction, etc. It can solve the problems of tea bending, affecting the service life of equipment, and poor tidying effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

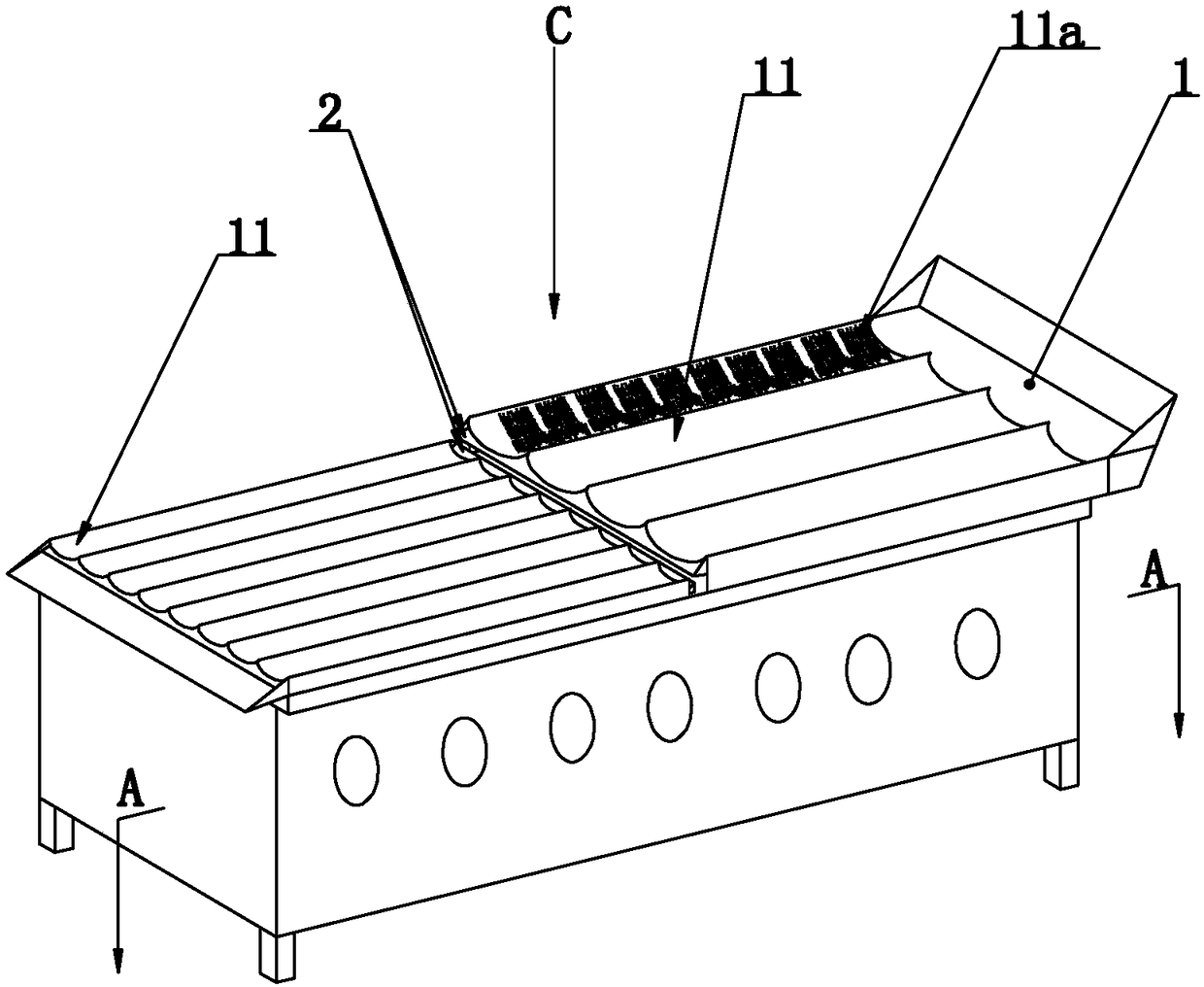

[0038] Such as Figure 1 ~ Figure 4 As shown, the present invention discloses a multi-slot pot for making tea. In a specific embodiment of the present invention, more than two independent U-shaped pot bodies 1 are arranged at intervals along the length direction; each independent U-shaped pot body 1 is arranged along the The length direction is arranged in a ladder shape, and a feeding assembly 2 for transporting tea from the front independent U-shaped pot 1 to the rear independent U-shaped pot 1 is provided between adjacent independent U-shaped pots 1 .

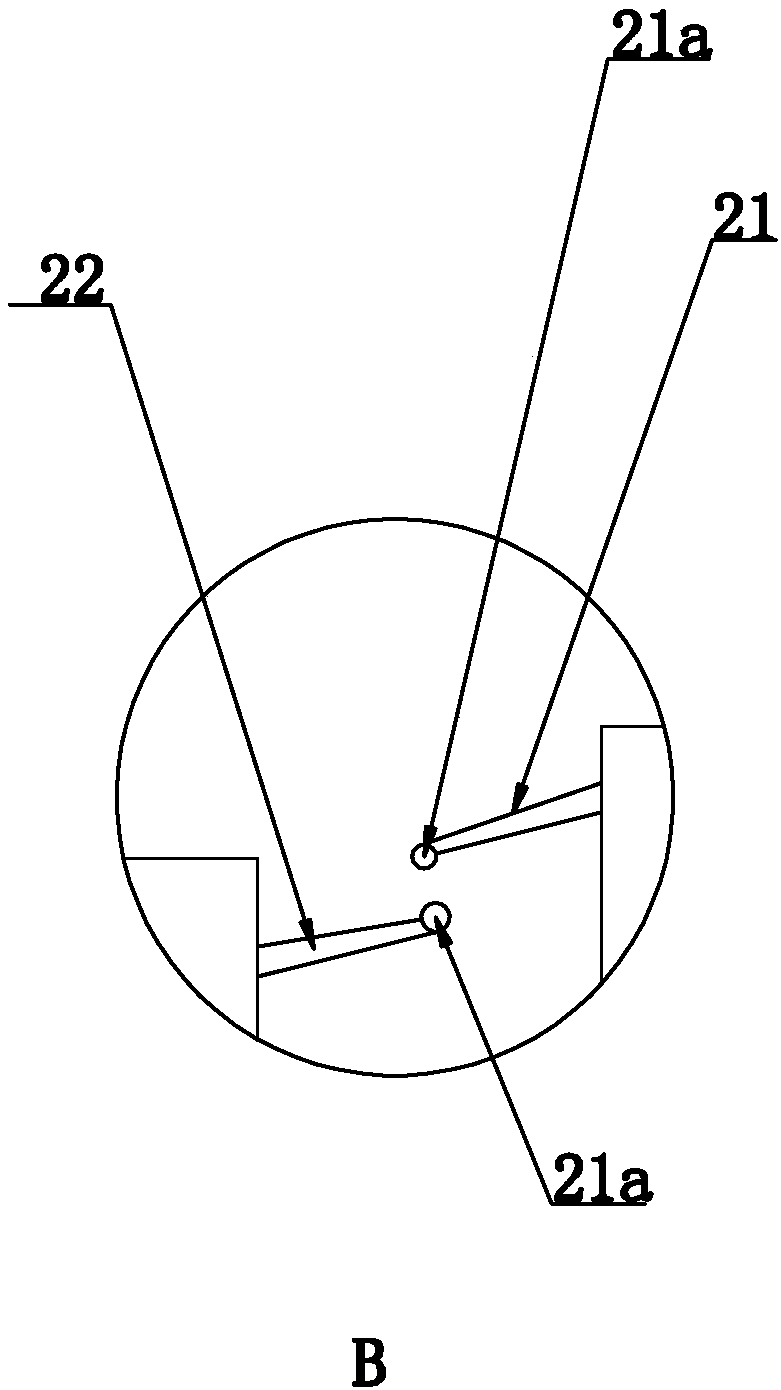

[0039] In a specific embodiment of the present invention, the material transfer assembly 2 includes a transfer plate 21 fixed at the discharge port of the front independent U-shaped pot 1 and a receiving plate 22 fixed at the feed port of the rear independent U-shaped pot 1 , the transfer plate 21 is located above the feed inlet of the receiving plate 22, and the transfer plate 21 and the receiving plate 22 partially overlap...

Embodiment 2

[0051] Embodiment 2, the difference with embodiment 1 is

[0052] Such as Figure 5 As shown, in a specific embodiment of the present invention, the groove width L1 of the U-shaped groove plate 11 constituting the front U-shaped pot body 1 may be smaller than the groove width L2 of the U-shaped groove plate 11 constituting the rear U-shaped pot body 1 .

[0053] By adopting the above-mentioned technical scheme: since there are many kinds of tea leaves, this technical means can be adopted when dealing with some tea leaves with large leaf area, that is, the groove width of the U-shaped groove plate of the front U-shaped pot body is smaller than that of the rear U-shaped pot. The setting of the groove width of the U-shaped groove plate of the shaped pot body; the beneficial effect of this setting is: when the tea leaves enter the U-shaped groove plate with a wider groove width from the U-shaped groove plate with a narrower groove width, it can effectively Improve the air permeab...

Embodiment 3

[0054] Embodiment 3, the difference with embodiment 1 is

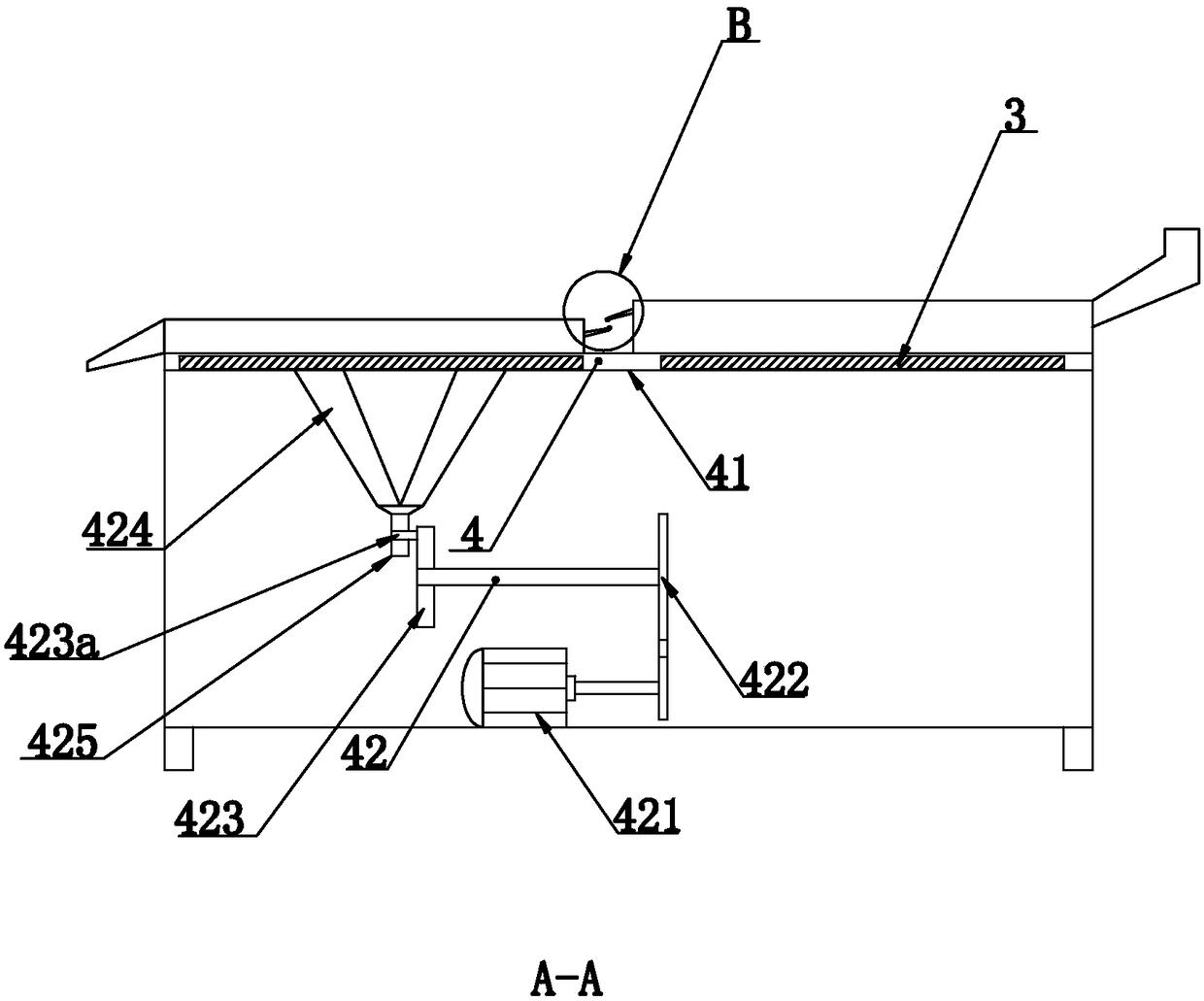

[0055] Such as Figure 6 As shown, in the specific embodiment of the present invention, the bottom of each independent U-shaped pot body 1 is provided with a driving assembly 4 that respectively drives each independent U-shaped pot body 1 to reciprocate and swing.

[0056] By adopting the above technical scheme, different driving components drive different independent U-shaped pots to move, which can increase the rolling range of tea leaves, improve the efficiency of tea drying, make tea leaves easier to shape, and further improve the quality of the tea leaves. Effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com