Method for predicting deformation of additive manufacturing part

A technology for additive manufacturing and parts, applied in the field of predicting the deformation of additive manufacturing parts, it can solve the problems of large-scale calculation and low efficiency of large and medium-sized parts in additive manufacturing, which can reduce the calculation time, simplify the calculation process, and improve the The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The method for predicting deformation of additively manufactured parts according to the present invention will be described in detail below with reference to the accompanying drawings.

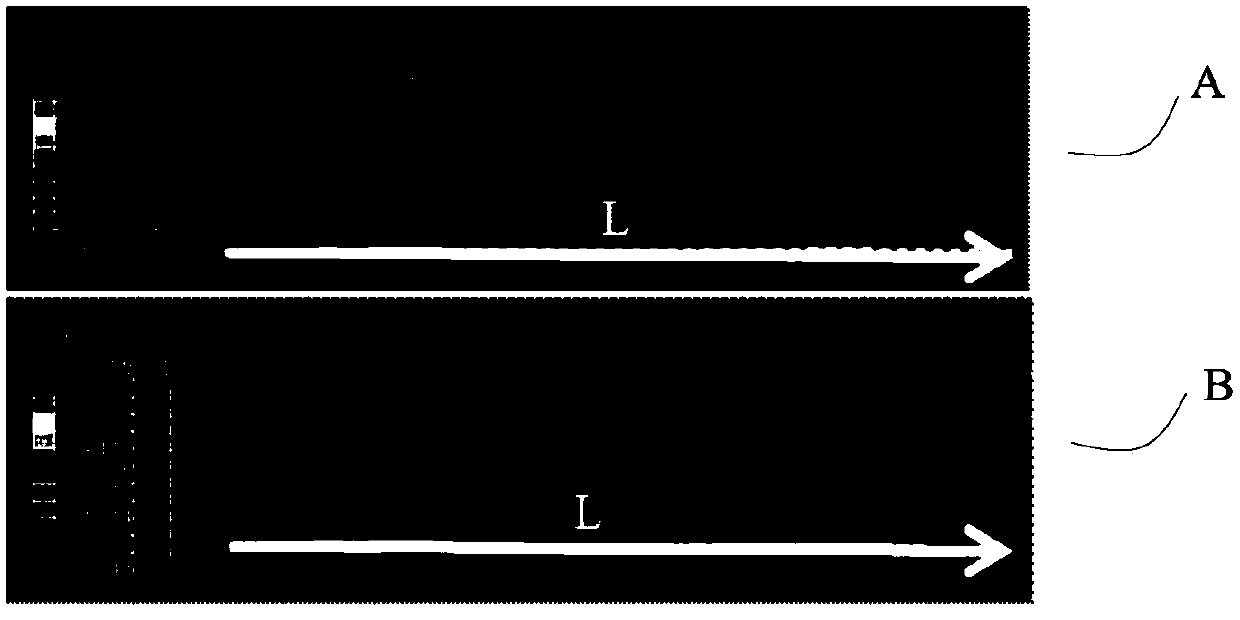

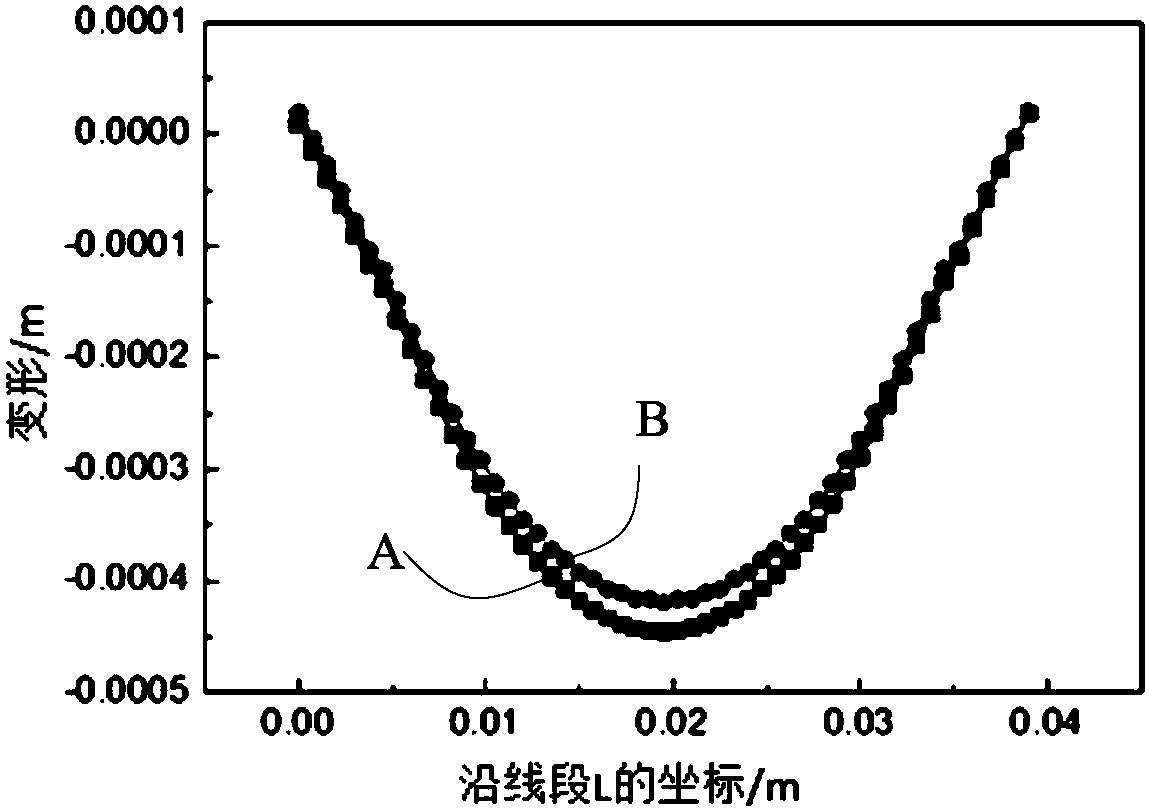

[0027] refer to Figure 1 to Figure 3 , the method for predicting the deformation of additively manufactured parts according to the present invention includes steps: S1, S2, S3 and S4.

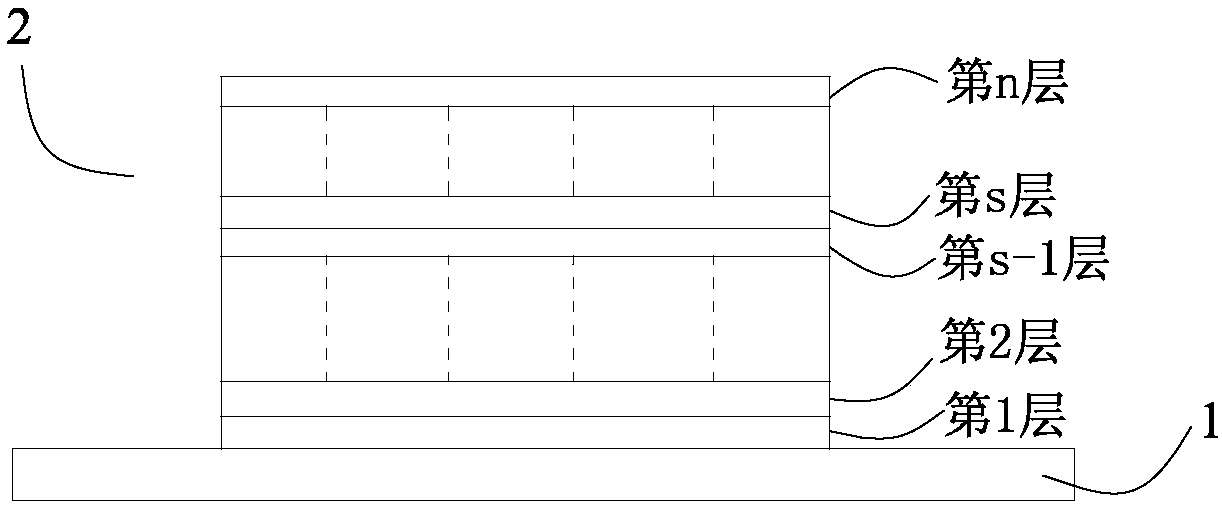

[0028] S1, establish a three-dimensional solid model 1 of a pre-printed part formed by stacking n-layer metal units on the substrate 2 (such as figure 1 shown), wherein the first layer metal unit is the lowermost metal unit of the three-dimensional solid model 1 of the pre-printed part, the n-th layer metal unit is the uppermost metal unit of the three-dimensional solid model 1 of the pre-printed part, and the pre-printed The length direction of the three-dimensional solid model 1 of the part is the x direction, the width direction is the y direction, the height direction is the z direction, and the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com