Fresh air system for industrial control room

A technology of fresh air system and industrial control, applied in the application, home heating, home heating and other directions, can solve the problems of complicated pipe connection operation, poor adaptability, and inability to connect indoor pipes, and achieve good adaptability and simple structure. , the effect of convenient connection and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

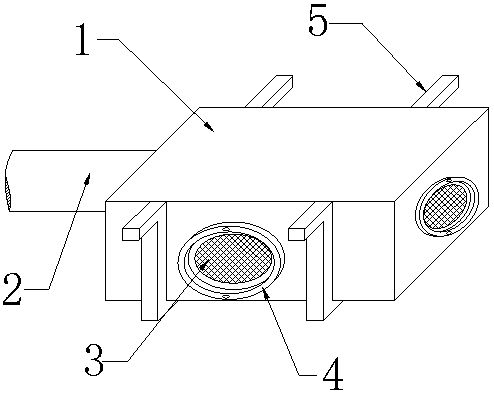

Image

Examples

specific Embodiment approach

[0020] Specific implementation method: when the user installs the device, the upper side of the installation frame 5 is fitted to the ceiling, and then the installation frame 5 is fixed on the ceiling by expansion bolts to realize the installation of the fresh air blower body 1, and the control in a small space When used inside the room, the air is delivered directly through the vent 3. When used inside the control room with a large space, the user connects the indoor pipe 43. When connecting, the user puts the compression ring 47 on the connecting ring 42, the annular side of the indoor pipe 43 on the right side, and then assemble the connecting ring 42 to the inside of the fixed cylinder 41, and make the left side of the connecting ring 42 fit the surface of the fresh air machine body 1, and the user moves the pressing ring 47 to press it tightly. The movement of the ring 47 drives the connecting ear 45 to move, so that the connecting ear 45 is assembled to the annular side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com