Preparation method of high-performance, low-halogen, environment-friendly and flame-retardant steel wire rope core conveyer belt

A steel cord core and high-performance technology, which is applied in the field of rubber conveyor belts, can solve problems such as unevenness, rough appearance, and uneven thickness of cover rubber, and achieve the effects of less time consumption, reduced personnel demand, and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preparation method of a high-performance low-halogen environment-friendly flame-retardant steel cord conveyor belt of the present invention will be specifically described below in conjunction with specific examples.

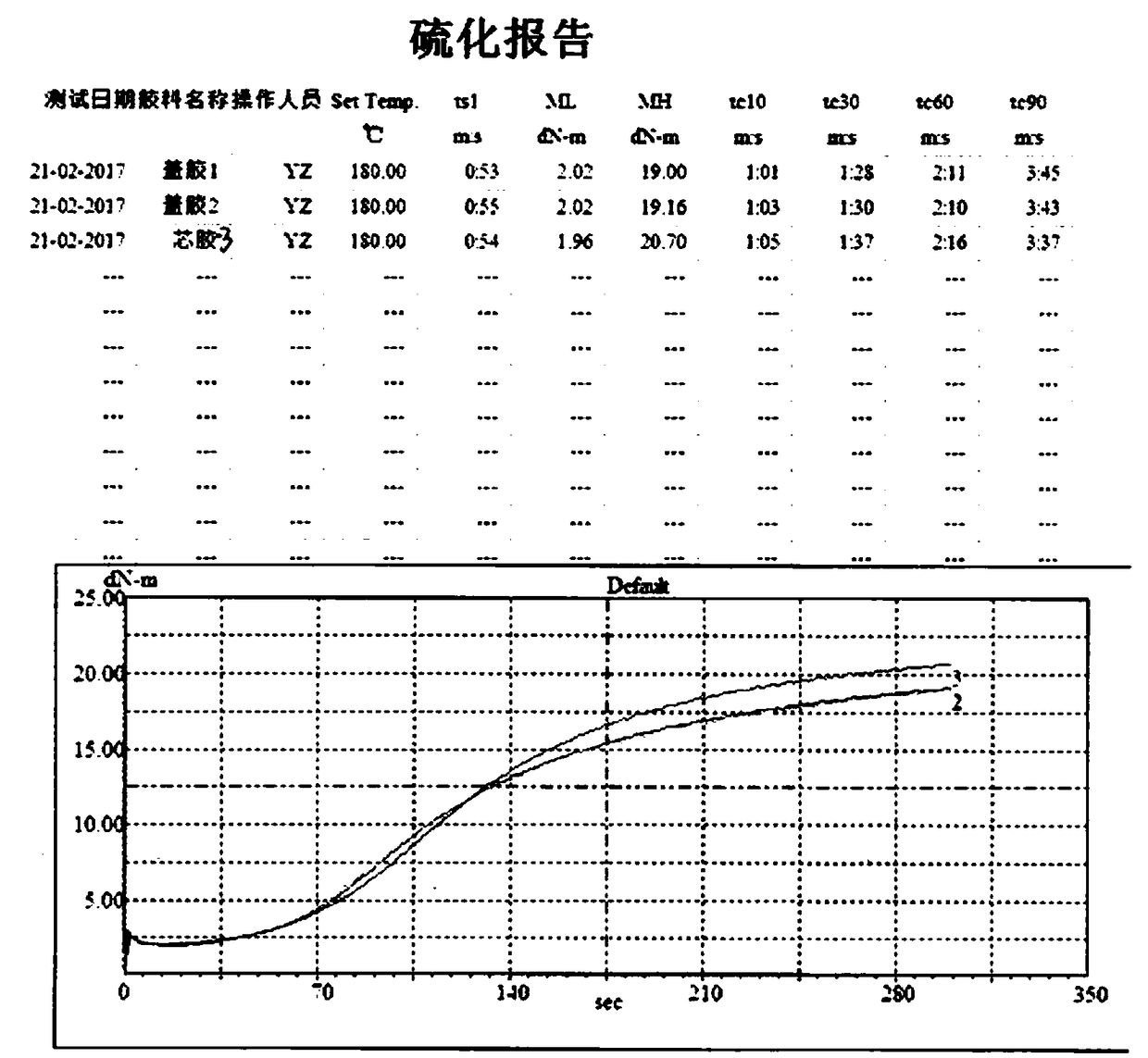

[0020] The formula of the preparation method of the high-performance low-halogen environment-friendly flame-retardant steel cord conveyor belt consists of the following raw materials in parts by weight: 60.0 parts of styrene-butadiene rubber, 20.0 parts of butadiene rubber, 20.0 parts of standard rubber, 6.0 parts of indirect zinc oxide, 0.8 parts of anti-aging agent RD, 1.5 parts of anti-aging agent 4010NA, 1.5 parts of paraffin, 18.0 parts of 70# chlorinated paraffin, 7.0 parts of antimony trioxide (grade 0), 8.0 parts of ammonium polyphosphate, 30.0 parts of flame retardant WX-01, 12.0 parts of flame retardant WX-02, 15.0 parts of flame retardant WX-03, 1.2 parts of accelerator CZ, 0.6 parts of accelerator DM, 45.0 parts of carbon black N234, 3.0 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com