Aviation packaging plate servo stacking device

A technology of stacking devices and pallets, which is applied in packaging, transportation and packaging, rigid containers, etc., can solve the problems of slow stacking speed of pallets, long time for boarding, and increased cost, and achieve convenient and fast unloading methods, Improve the stacking speed and increase the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

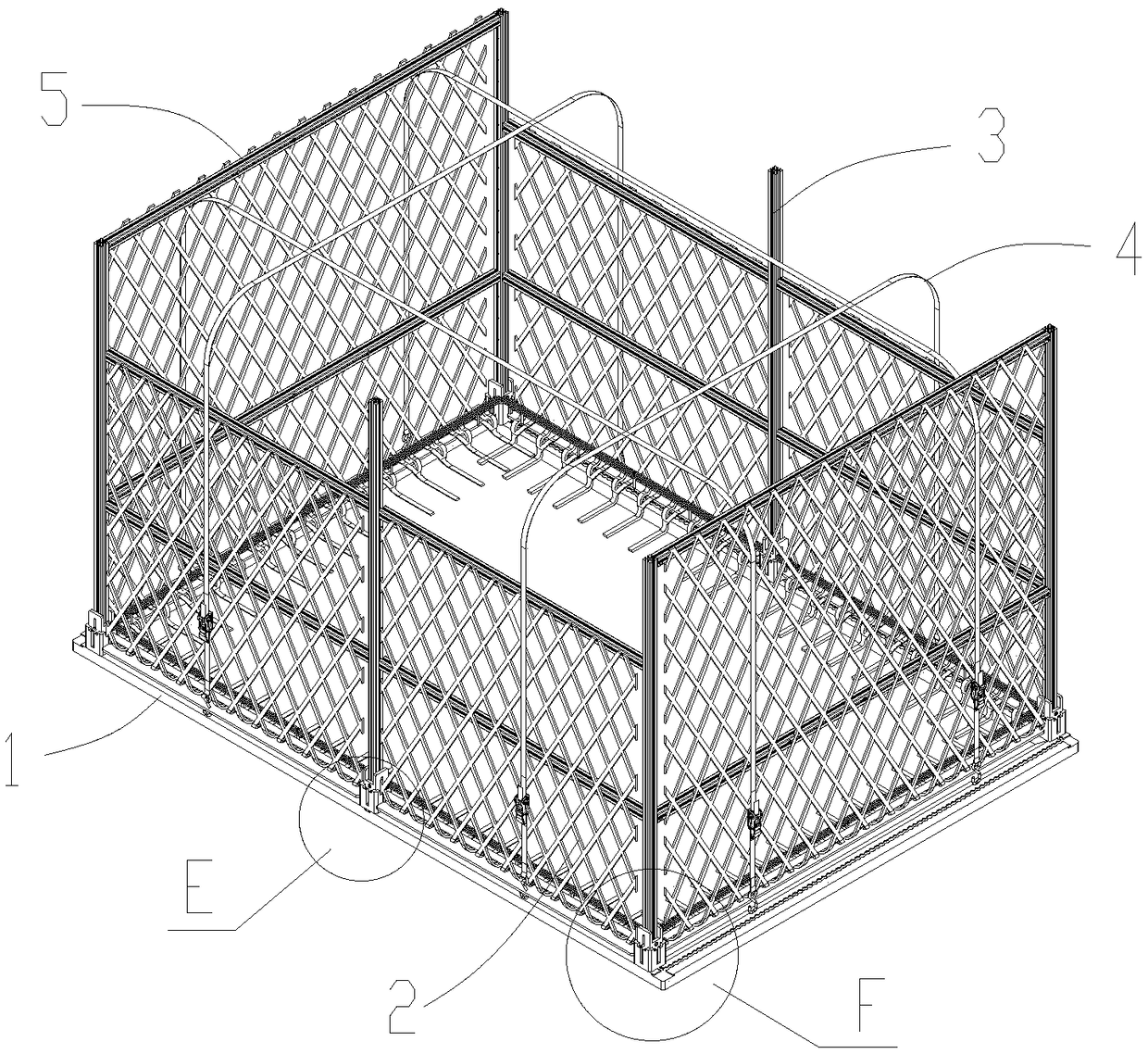

[0033] In this embodiment, a kind of follow-up stacking device for aviation pallets, see figure 1 , Figure 4 , based on a rectangular support base plate 1, six uprights 3 are set at the four corners of the support base plate 1 and the middle of the long side, and a liftable static rope net 2 is arranged between adjacent uprights 3; the static rope The bottom edge of the net 2 is connected on the winding mechanism, and the top edge of the static rope net 2 is arranged on the rigid fastening mechanism.

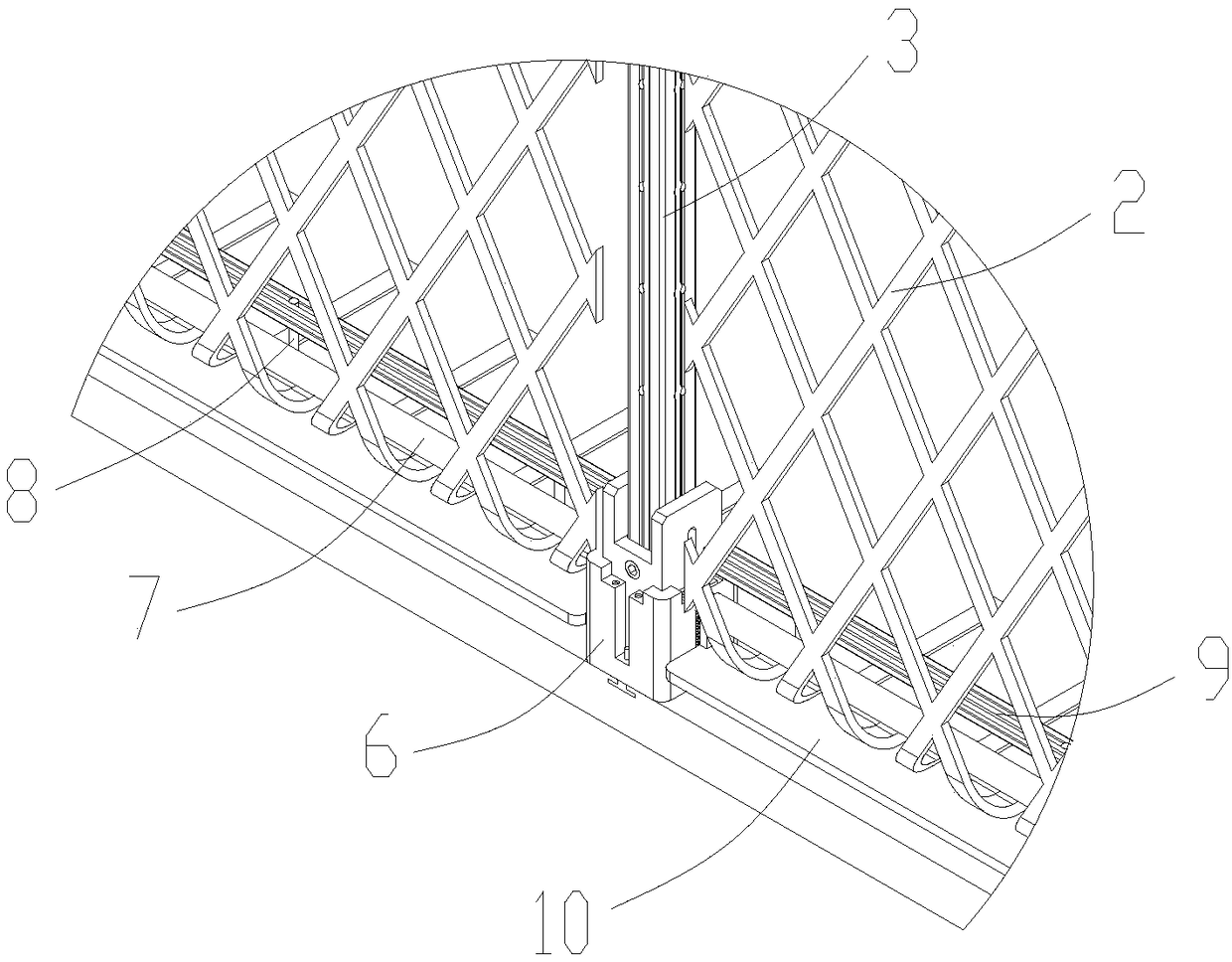

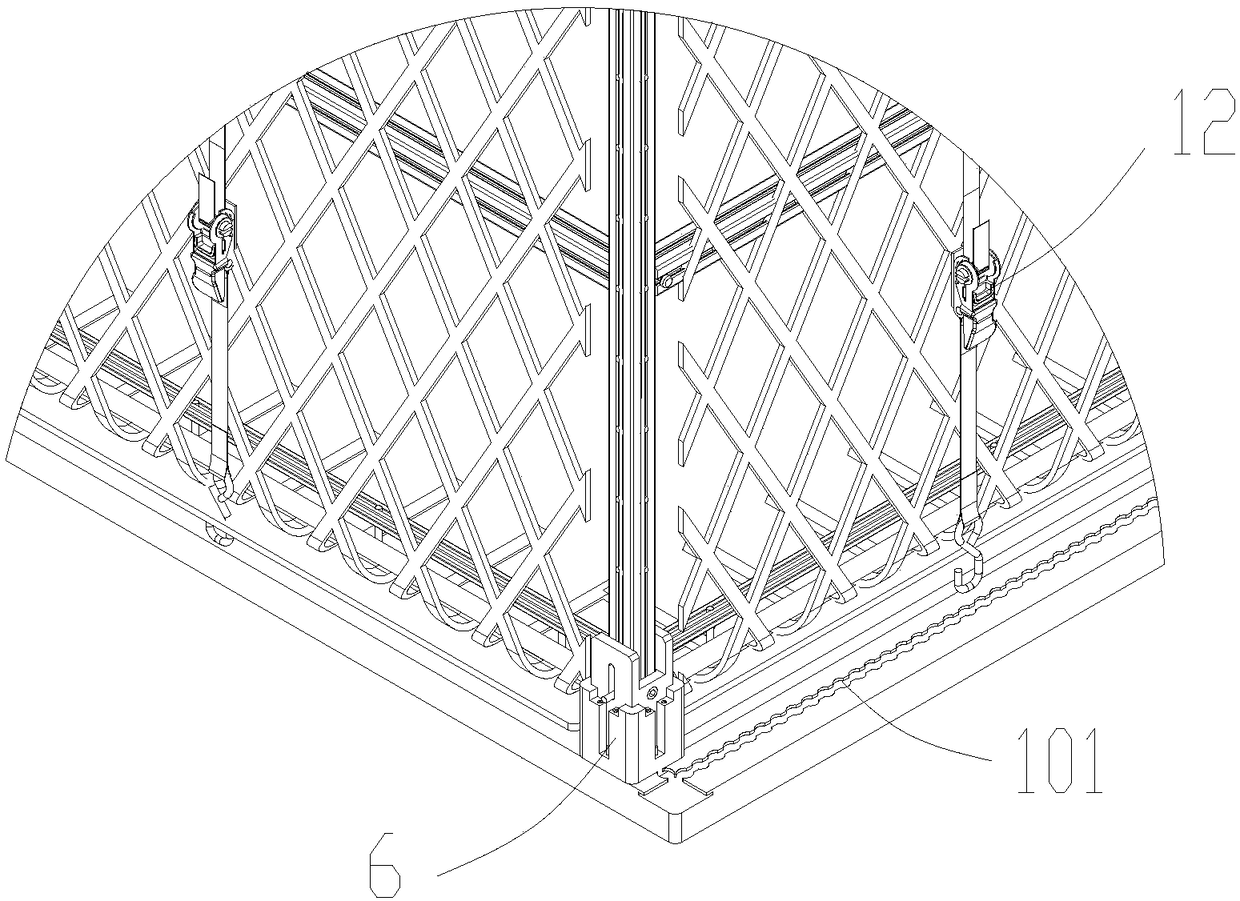

[0034] In the following, it will be specifically described. In the surrounding plane of the support base plate 1, an inverted T-shaped corrugated guide groove 101 is provided along its edge, such as image 3 , Figure 5 As shown, the column base 6 is installed through the corrugated guide groove 101 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com