Linkage multi-level telescopic blank receiving device

A receiving device and telescopic technology, which is applied in the field of linkage multi-stage telescopic embryo body receiving device, can solve the problems of succession, complex structure, etc., simplify the process action, improve the green body yield, shorten the The effect of transport time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

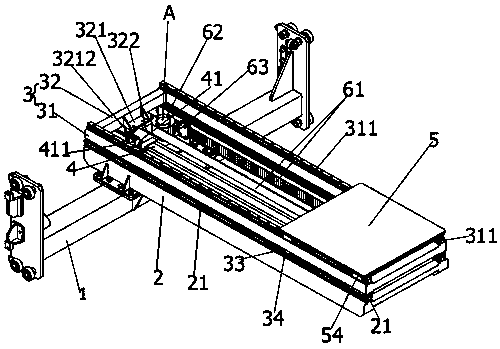

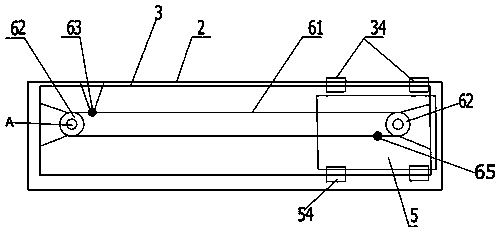

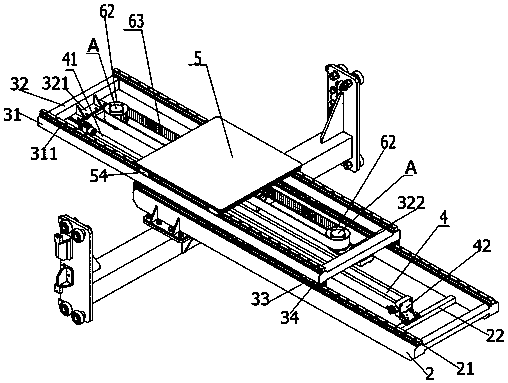

[0037] combine figure 1 , image 3 and Figure 5 As shown, it is a linkage multi-stage retractable embryo body receiving device in a preferred embodiment of the present invention, which includes a lifting beam frame 1, a bottom frame 2, a sliding frame 3, a cylinder 4 (driving device), and a stripped embryo receiving device. Tackle 5, linkage mechanism 6. The structure of each part and the overall working principle are introduced in detail below.

[0038] The lifting beam frame 1 can be vertically lifted and lowered by a chain drive, and stops at an appropriate position and height according to the process requirements, and is used for supporting and installing the bottom frame 2 .

[0039]A sliding frame 3 is slidably combined above the bottom frame 2 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com