Fast clamping device for cylinder head and cylinder sleeve

A technology of clamping device and cylinder liner, which is applied in the field of quick clamping device of cylinder head and cylinder liner, can solve problems such as inaccurate positioning of cylinder liner, easy swing of cylinder liner, poor coaxiality of products, etc., and achieve good coaxiality , Avoid shaking and displacement, and the effect of high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

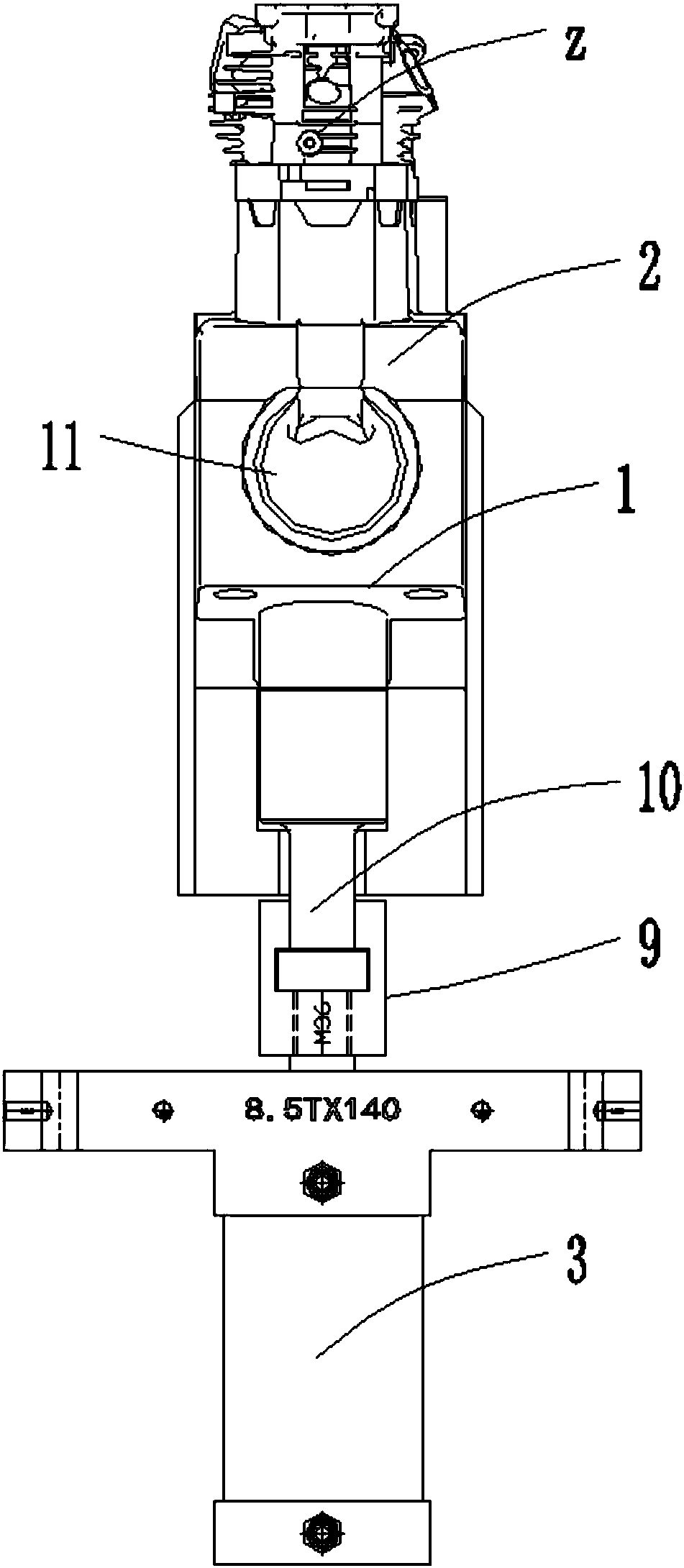

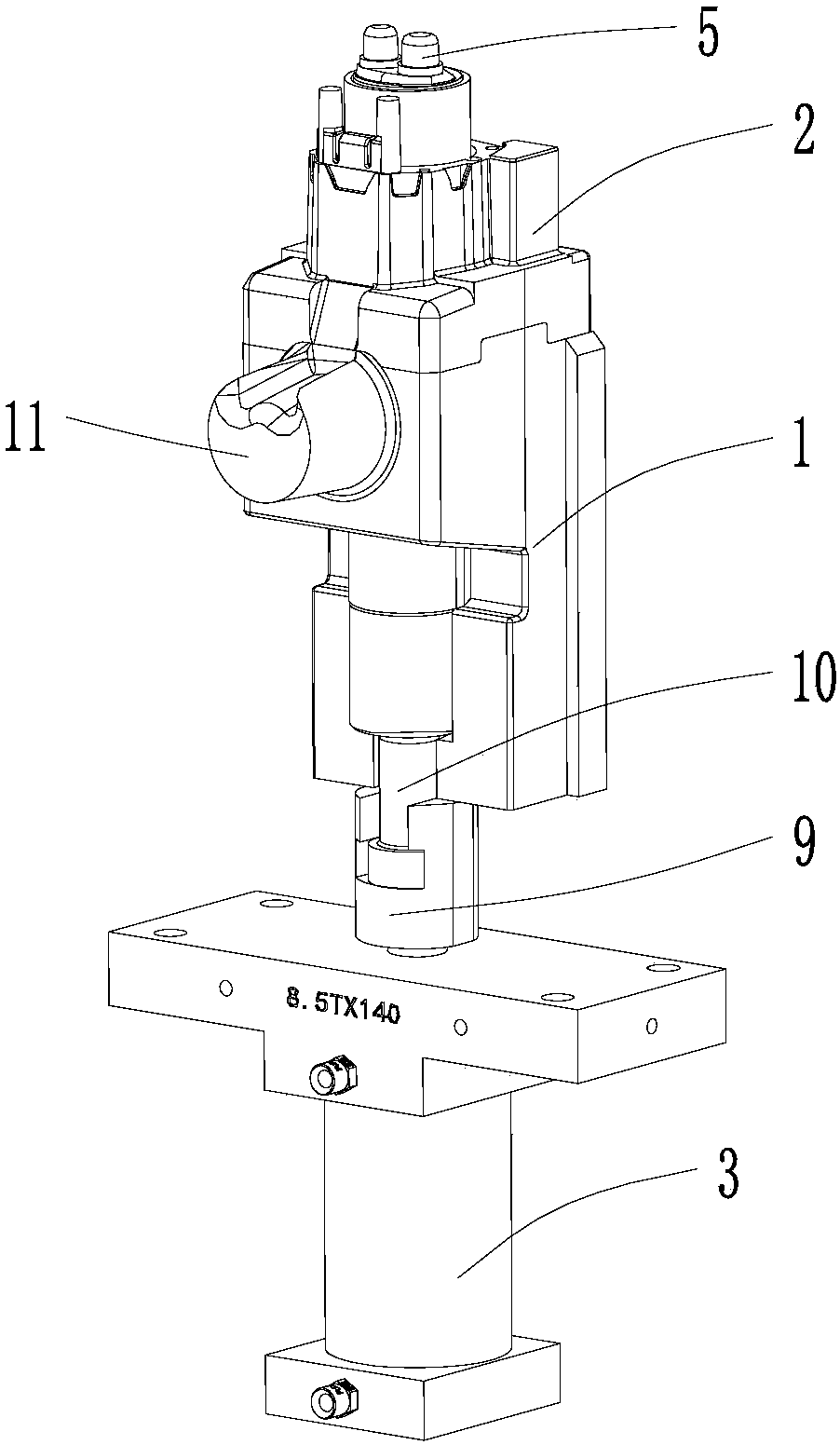

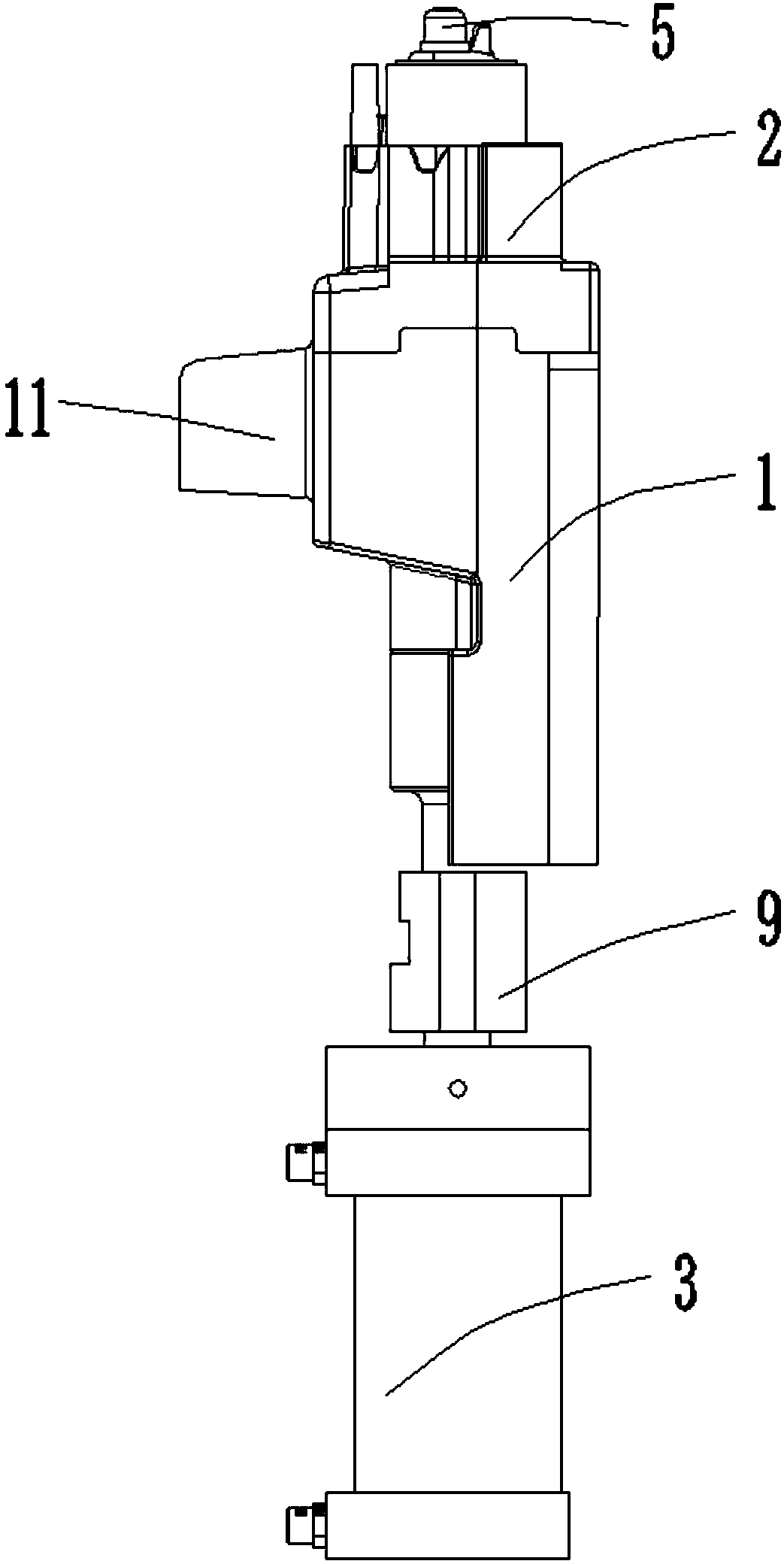

[0028] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] Such as Figure 1-7 As shown, a quick clamping device for a cylinder head and cylinder liner includes a slider 1, a slider 2, and an oil cylinder 3. The upper end of the slider 1 is fixedly connected to the lower end of the slider 2, and a Pull rod 4, the lower end of the pull rod 4 is connected with the piston rod of the oil cylinder 3, the top of the pull rod 4 stretches into the cylinder liner 5 provided in the slider 2, and the upper end of the pull rod 4 is provided with Guide chute 6, which is provided with a wedging block 7 in the guide chute 6, and a fixed block 8 is connected to the wedged block 7, and the outer end of the fixed block 8 can extend out of the cylinder liner column 5 for It is in contact with the inner wall of the cylinder liner to realize the expansion and fixation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com