Car shell model material recovery device

A model material and recovery device technology, applied in transportation and packaging, grain processing, chemical instruments and methods, etc., can solve problems such as inconvenient operation, affecting the effect of secondary use, and uneven density of sludge, so as to avoid air bubbles Residual, easy to operate, reduce intermittent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further detailed explanation through specific implementation mode below:

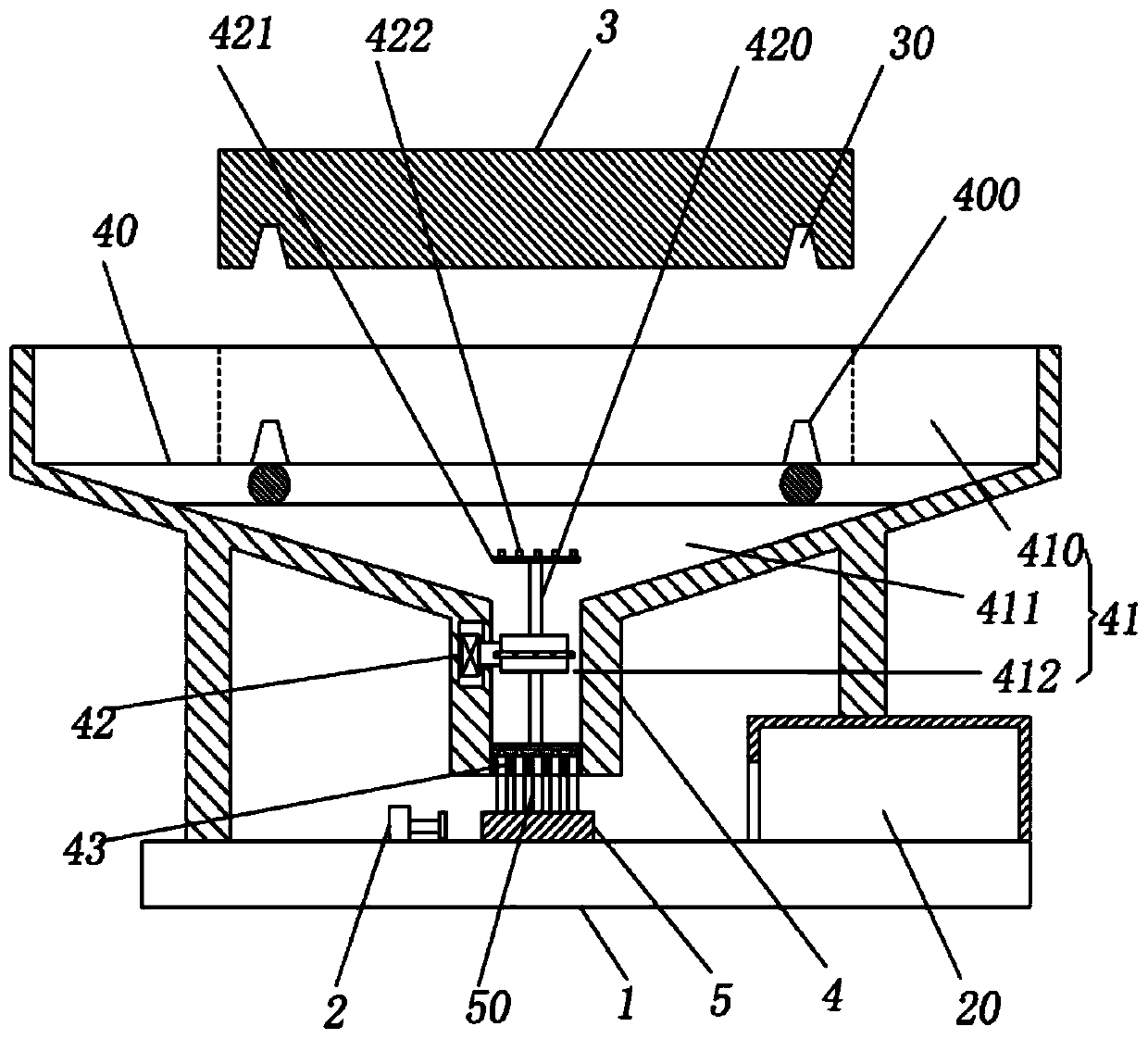

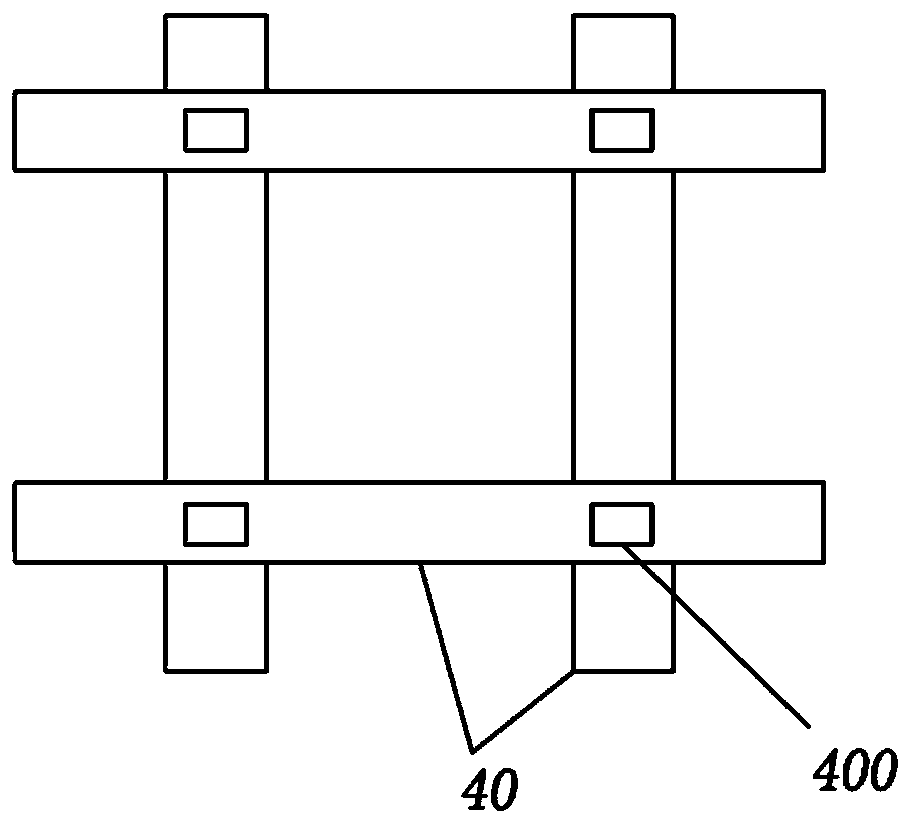

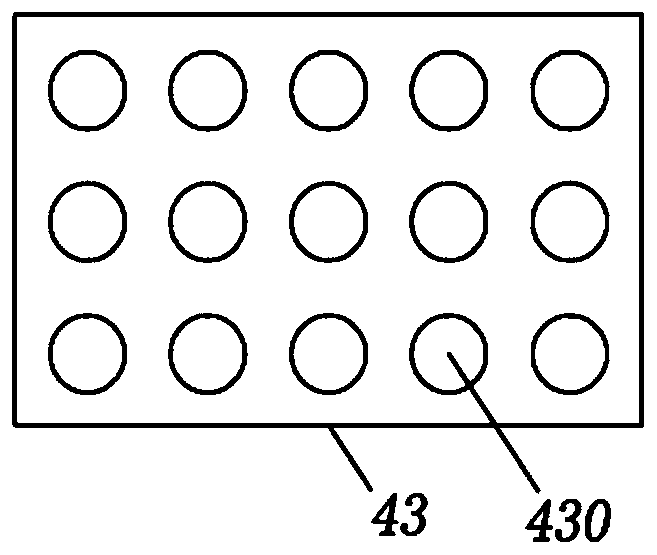

[0020] The reference signs in the drawings of the description include: frame 1, pneumatic cylinder 2, oven 20, workbench 3, groove 30, collection box 4, support frame 40, bump 400, receiving cavity 41, and blanking cavity 410 , sliding chamber 411, collecting chamber 412, second motor 42, crushing knife rod 420, extruding rod 421, elastic block 422, blanking screen 43, blanking hole 430, support shell 5, collecting pipe 50, conveying roller 51. Circulation sleeve 52.

[0021] The embodiment is basically as figure 1 Shown: the car shell model material recovery device, including frame 1, workbench 3 and oven 20, collection box 4 and recovery box all installed on the frame 1.

[0022] The top opening design of the collection box 4 is preferably a square frame, and the top of the collection box 4 is welded with a support frame 40 for supporting the workbench 3 . The shape of the support frame 40 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com