Automatic electronic product assembling device and assembling manipulator thereof

A technology for automation group and electronic products, applied in the direction of electrical components, electrical components, etc., can solve the problems of cumbersome operation, long assembly line, difficult positioning and alignment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

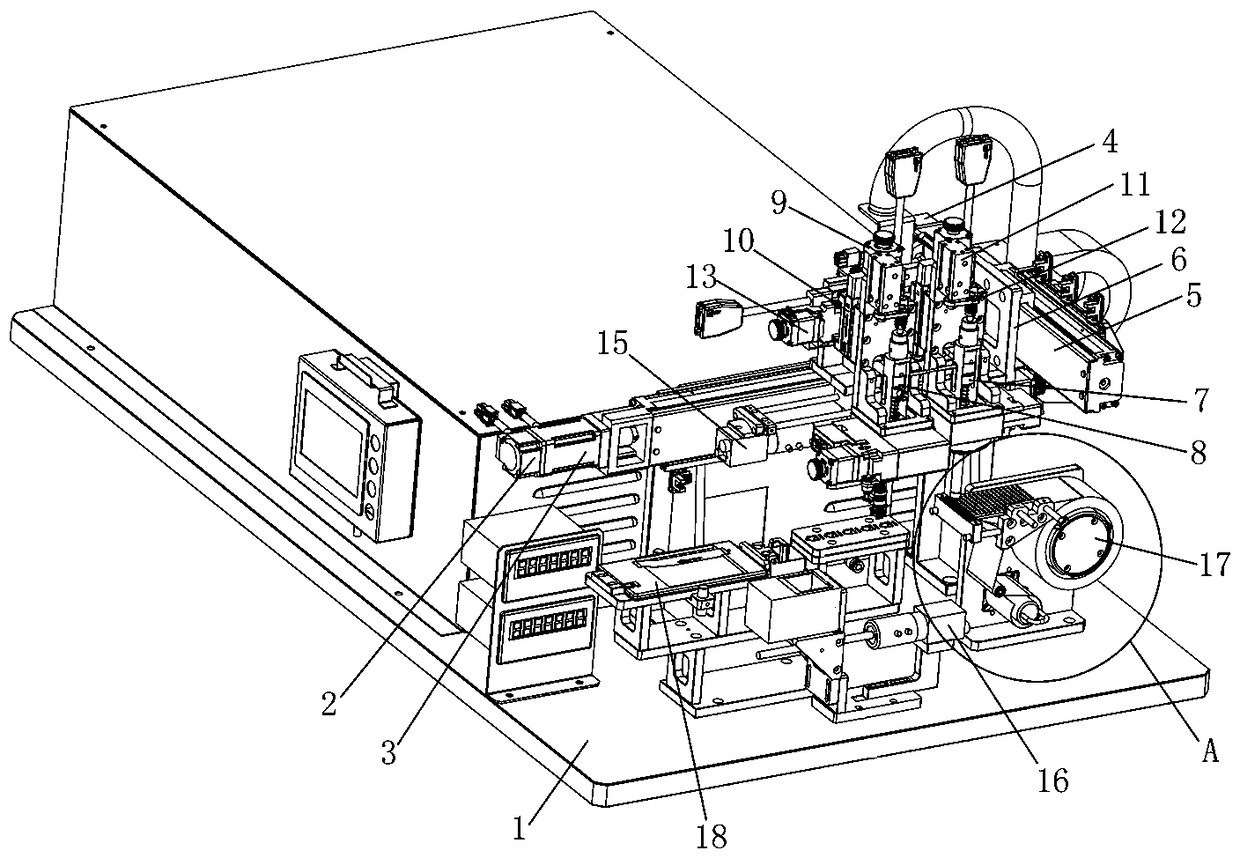

[0043] Embodiment 1: as Figure 1 to Figure 8 As shown, the technical solution adopted in Embodiment 1 of the present invention is as follows: an automatic assembly machine for electronic products, including a drive mechanism, a slide seat 6, a fine-tuning mechanism, a CCD mechanism, a feeding mechanism 17, a first assembly manipulator 7 and a second assembly Manipulator 8, wherein, the above-mentioned drive mechanism is arranged on the machine platform 1, and the drive mechanism includes a horizontal assembly, a vertical assembly connected to the horizontal assembly and a lifting assembly; the above-mentioned slide seat 6 is connected with the output end of the vertical assembly, and is passed through the horizontal assembly and the vertical assembly. The longitudinal assembly is driven to move linearly in the horizontal plane; the slide seat 6 is provided with two installation stations; The output ends are respectively arranged along the longitudinal direction and the transv...

Embodiment 2

[0064] Embodiment 2: as Figure 9 with Figure 10 As shown, it is a schematic diagram of the three-dimensional structure of the assembly manipulator in Embodiment 2 of the present invention. This embodiment can realize the pick-and-place and assembly of hard sheet materials such as cover plate c; the shaft arm, transmission assembly, and pressure sensor of this embodiment And the material suction assembly is the same as in embodiment 1; the vacuum adsorption material can be realized by the vacuum adsorption head 018 arranged at the lower end of the slide bar, and the real-time sensing of pressure when taking materials or assembling is realized by using a pressure sensor; the difference from embodiment 1 is In this embodiment, the clamping assembly is directly arranged on the slide bar, specifically: the transmission sleeve 016 of this embodiment is directly set on the lower part of the slide bar 08, and the support rod 014 in Example 1 is omitted. The structural design is sim...

Embodiment 3

[0065] Embodiment 3: as Figure 11 to Figure 13As shown, it is a schematic diagram of the three-dimensional structure of the assembly manipulator in Embodiment 3 of the present invention. The assembly manipulator of this embodiment is mainly used for picking and placing or assembling dual cameras, and the dual cameras include a first camera d and a second camera e; The shaft arm, transmission assembly, pressure sensor, and material suction assembly are the same as in Embodiment 1, and the first camera d is absorbed by the vacuum suction head at the lower end of the slide bar 08; the difference from Embodiment 1 is that the sleeve of the material clamping assembly in this embodiment 010 is not connected and fixed on the slide bar 08, but is fixedly connected to the lifting slide seat 10 of the lifting assembly, and extends to the side of the slide bar 08, and synchronizes the movement of the slide bar 08; the material clamping assembly of the present embodiment Cylinder 011, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com