Variable-current variable-speed non-commutated permanent magnet direct current motor

A DC motor without commutation technology, which is applied in the direction of motors, electric vehicles, electric components, etc., can solve the problem of large power consumption and achieve the effects of low power consumption, high utilization rate of permanent magnet energy, and fast torque response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail now in conjunction with accompanying drawing.

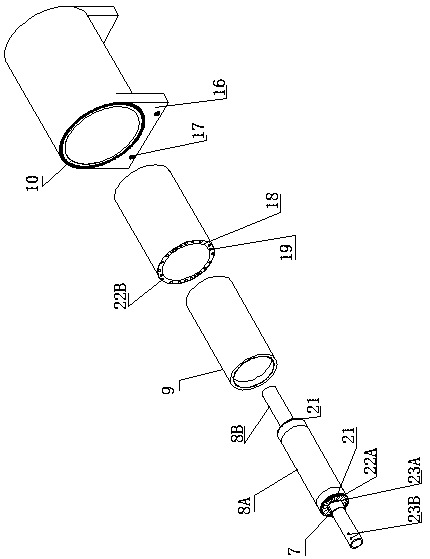

[0022] A variable-flow variable-speed non-commutation permanent magnet DC motor, including a machine base 16, a coil inner rotor 8A, a permanent magnet inner stator 9, a coil outer rotor 18, and a permanent magnet outer stator 10, and the coil inner rotor 8A is arranged on the permanent magnet inner stator 9, the permanent magnet inner stator 9 is arranged in the inner cavity of the coil outer rotor 18, the coil outer rotor 18 is arranged in the inner cavity of the permanent magnet outer stator 10, and the permanent magnet outer stator 10 is arranged on the base 16; It also includes rotor shaft 8B, rotor shaft support 2, rotor shaft magnetic suspension inner sleeve 6A, rotor shaft magnetic suspension outer sleeve 6B, support magnetic suspension inner sleeve 11B, support magnetic suspension coil outer sleeve 11A, and the two ends of rotor shaft 8B are arranged on two In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com