Roller extension socket

A roller, one-way roller technology, applied in contact parts, electrical components, coupling devices, etc., can solve the problems of exposed metal sheets, loose plugs, and difficult to use, and achieve the effect of humanized design, convenient control, and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

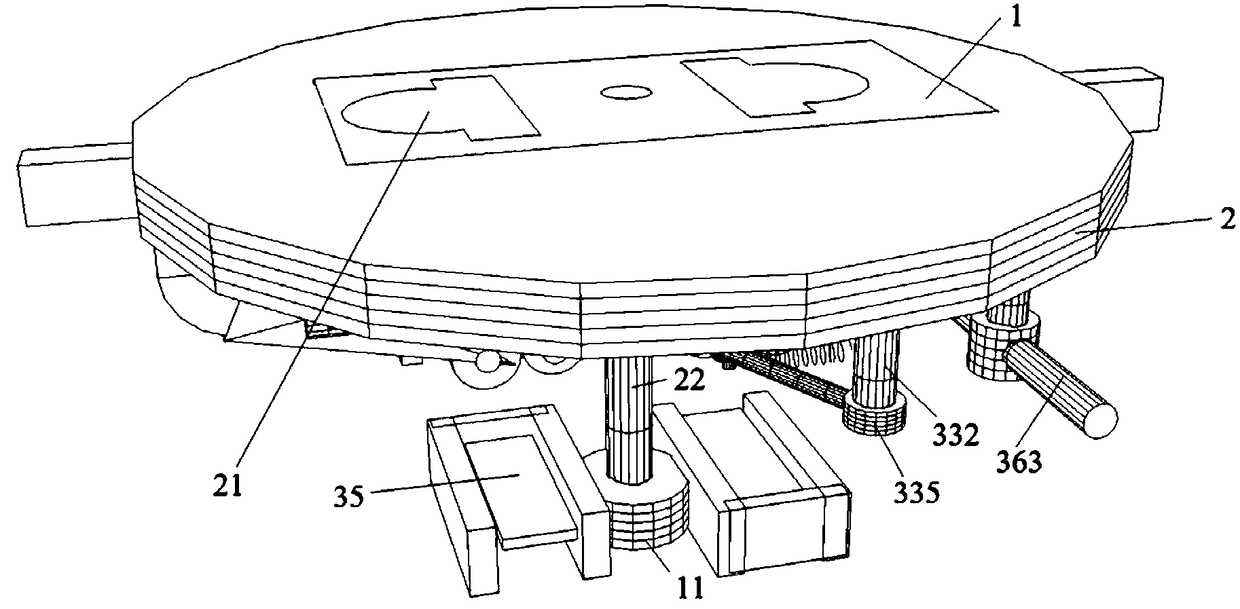

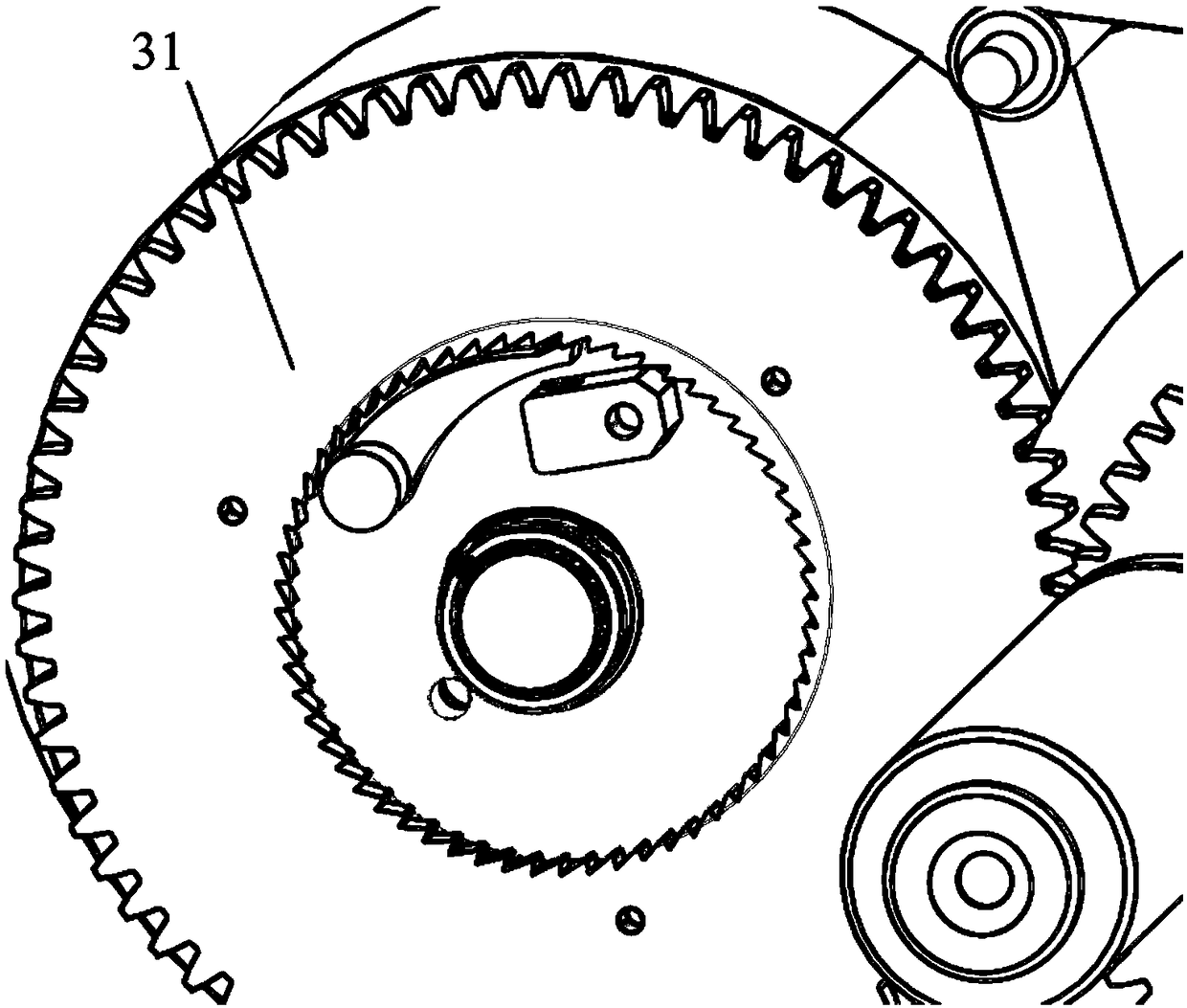

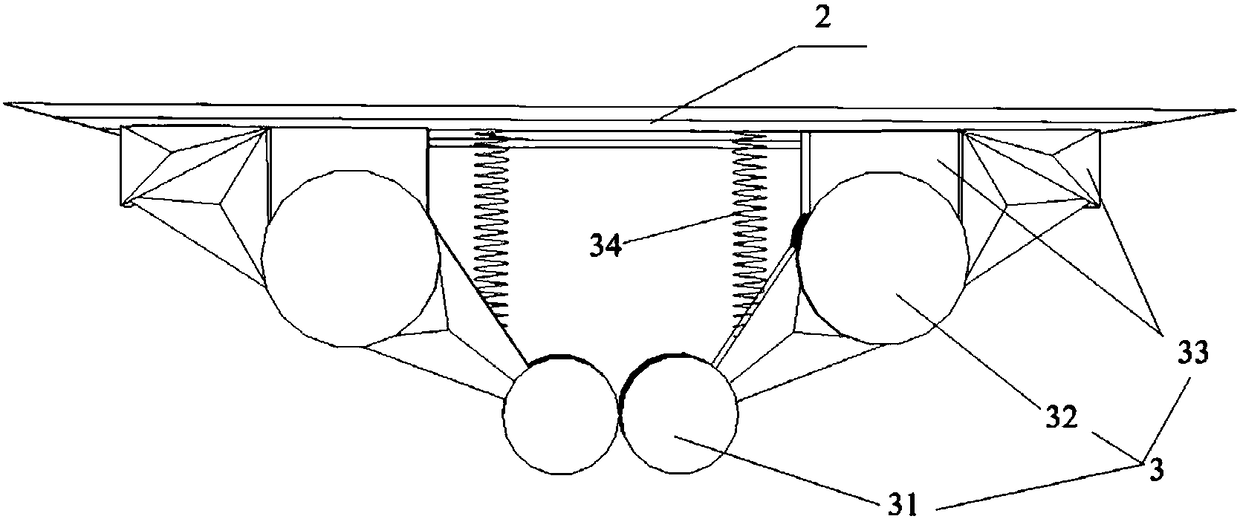

[0032] Such as figure 1 and figure 2 As shown in the roller socket, the roller socket is composed of a body 1, a turntable 2 and a clamping device 3, the turntable 2 rotates on the socket body 1, a socket 21 is provided on the turntable 2, and the clamping device 3 is installed on each socket. At the bottom of the hole 21 , the clamping device 3 is arranged symmetrically with respect to the insertion hole 21 ; the clamping device 3 includes a roller 31 , a moving shaft 32 , a fixing bracket 33 and a first spring 34 . A set of clamping devices 3 is arranged under each socket 21 , and the symmetrical clamping devices with respect to the socket 21 make the force of the entire clamping device uniform and the resistance is minimum, which is convenient for torque transmission.

[0033] Roller 31 is wrapped with rubber, is provided with a center rotating shaft 22 vertically downwards at the center of circle of rotating disc 2, and central rotating shaft 22 can only rotate countercl...

Embodiment 2

[0036] Since the distance between the metal sheets 100 of the plug is fixed, only 1.15cm, and the installation space required by the fixed bracket in Embodiment 1 is relatively large, in order to better realize the technical effect in Embodiment 1, this In the embodiment, the specific structure of the roller socket is improved to the following structure. The improved internal structure of each jack is asymmetrical, which simplifies the structure on one side, and the unmentioned part of the structure is the same as that of Embodiment 1.

[0037] Such as Figure 3 ~ Figure 5 As shown, the two sides of the clockwork device 11 are provided with card slots, and a metal elastic piece 35 is arranged in the card slot, and the second spring 12 is connected to the lower part of the metal elastic piece 35 . The clockwork device 11 and the second spring 12 are fixed on the main body 1. The second spring 12 provides support for the metal dome 35 when the metal piece 100 is inserted, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com