Impregnation method for solid-state aluminum electrolytic capacitor

An aluminum electrolytic capacitor, solid-state technology, used in solid electrolytic capacitors, drying/dipping machines, etc., can solve the problems of low impregnation efficiency, fewer elements, lack of flexibility, etc., to improve impregnation quality, high efficiency and improve impregnation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

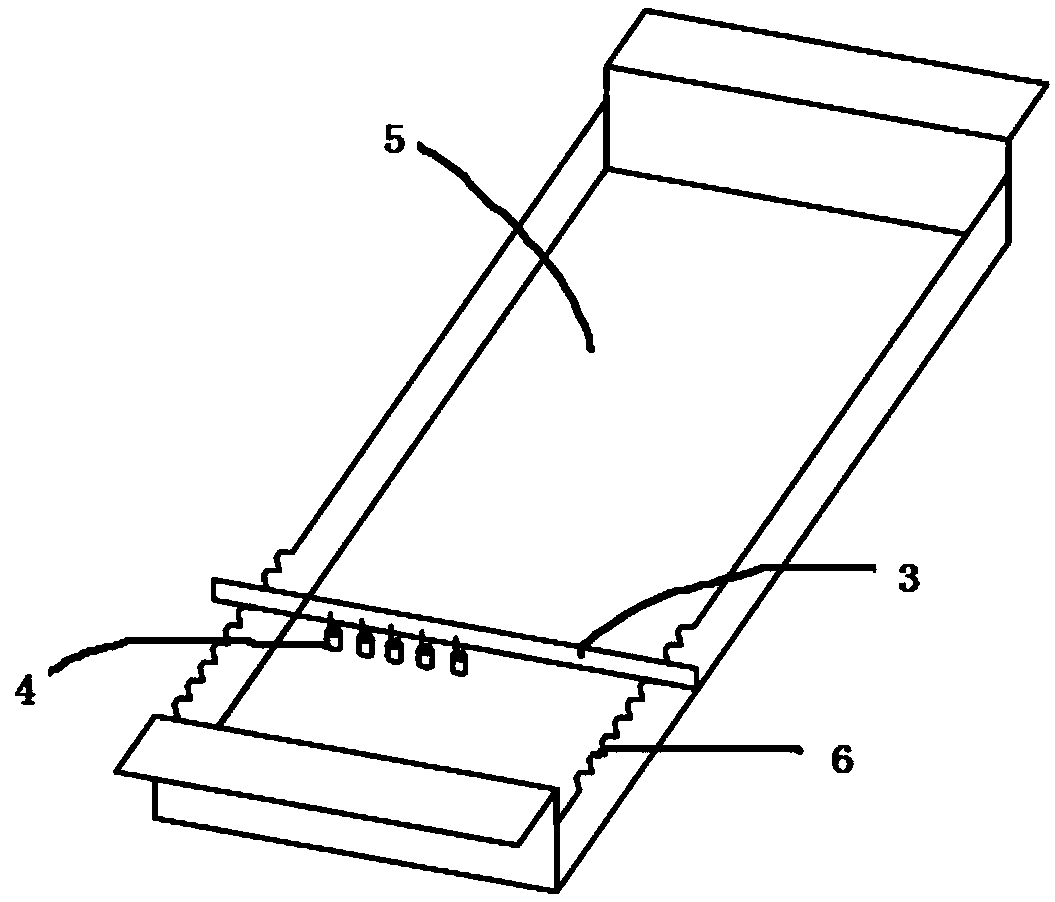

[0053] Embodiment 1: as Figure 3-6 , an impregnation device for a solid aluminum electrolytic capacitor, comprising an impregnation container 5, a side plate 1, a bar 3 and a element 4;

[0054] The impregnation container is a square container without a cover;

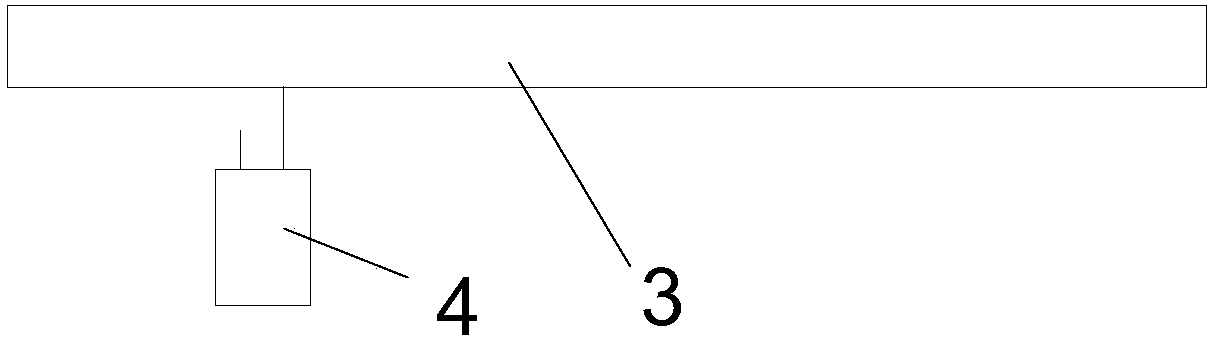

[0055] Both sides of the impregnation container are equipped with guide mechanisms, and the side plates are arranged in the guide mechanisms, and can slide along the length direction of the guide mechanisms. There are two side plates, and one end of each side plate is provided with a row for shelving The V-shaped groove 6 of the horizontal bar;

[0056] There are multiple horizontal bars, and multiple elements are arranged on each horizontal bar.

[0057] A plurality of elements on each horizontal bar are arranged at equal intervals.

[0058] Elements on adjacent horizontal bars are arranged in a staggered manner.

[0059] The guiding mechanism is the guiding slot 2 .

[0060] A liquid level detection device is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com