An adjustment device, measurement and compensation method for installation angles of multiple probes

A technology for installing angle and adjusting devices, which is applied in the direction of measuring devices, feedback control, instruments, etc., can solve problems such as poor flexibility of angle adjustment devices or instruments, manufacturing errors of device parts, and errors that cannot be eliminated, so as to shorten the adjustment time , improve the accuracy of the installation angle, and improve the effect of difficult adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing, present embodiment is described further:

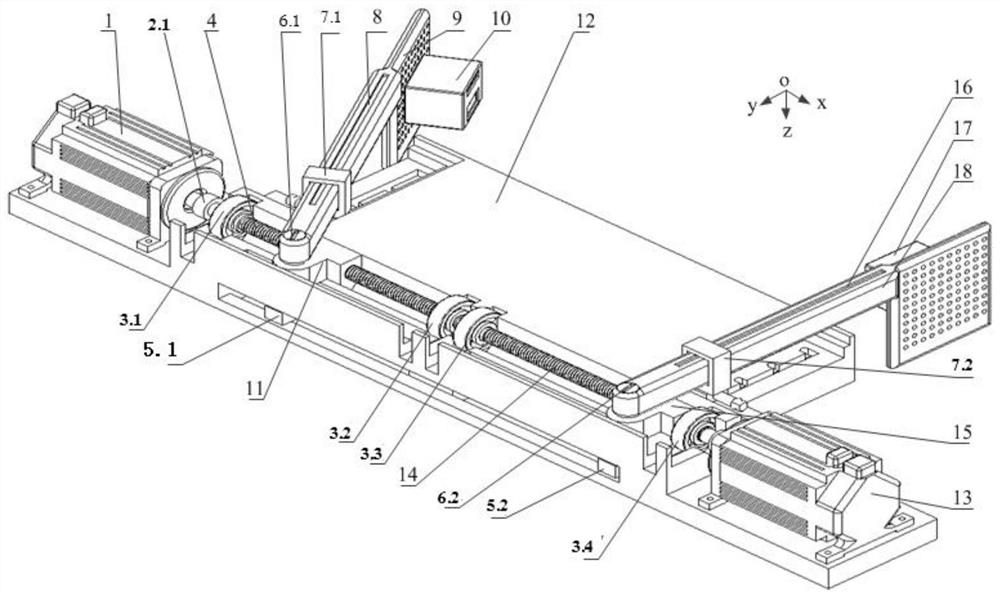

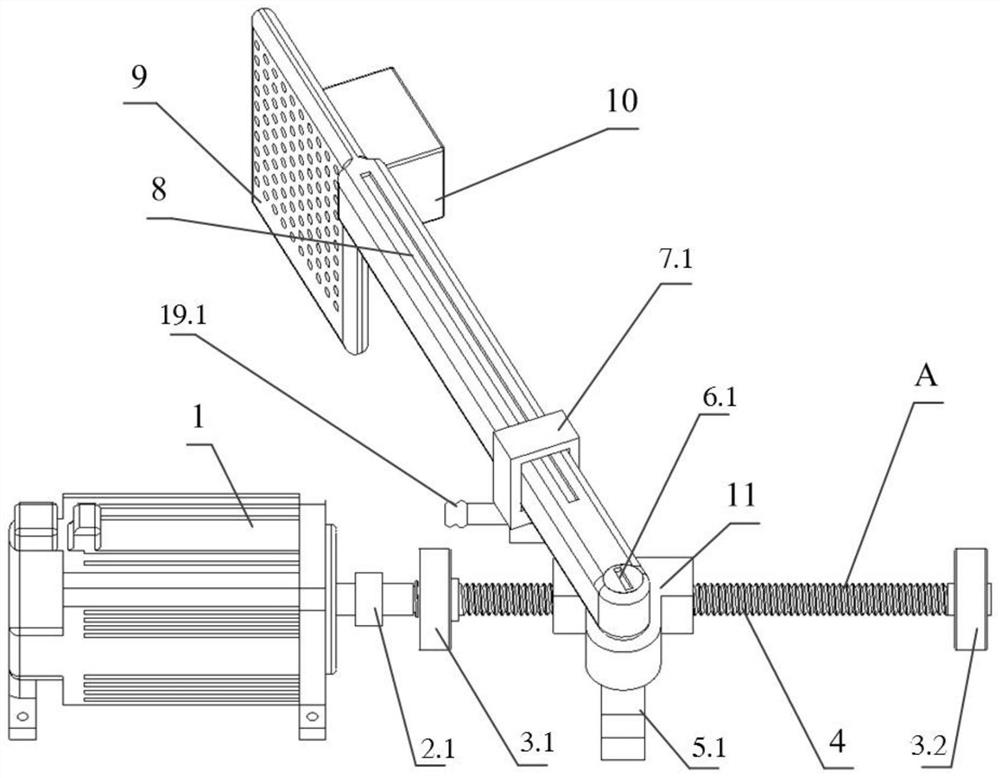

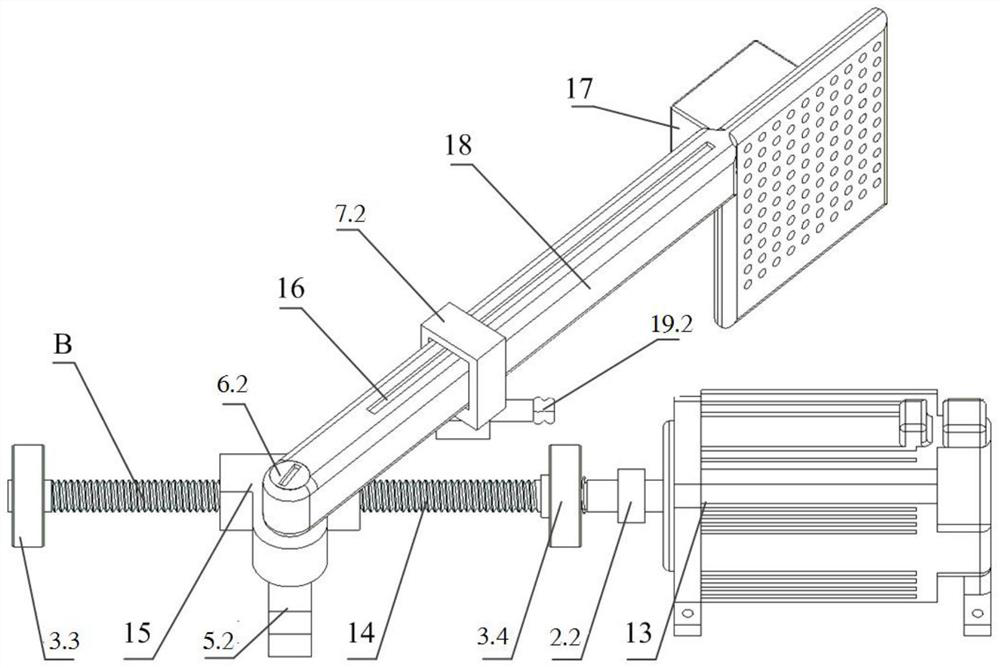

[0043] The working principle of the present invention is as figure 1 As shown, each structural member Figure 2-4 As shown, a multi-probe installation angle adjustment device is composed of a workbench (12), a left adjustment and measurement system (A) and a right adjustment measurement system (B). The left adjustment and measurement system (A) and the right adjustment and measurement system (B) are arranged symmetrically on the workbench (12).

[0044] In the left adjusting and measuring system (A): the left laser measuring head (10) is fixed on the preset hole at one end of the left mounting arm (9) through a refined lock nut, and the axial long grating of the left mounting arm (8) Installed in the axial direction of the upper end of the left mounting arm (9), the other end of the left mounting arm (9) is connected with the left special nut (11) and the horizontal fine-tuning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com