Preparation method of tin dioxide-based gas sensitive material and hydrogen sulfide gas sensor chip, hydrogen sulfide gas sensor

A gas sensor, tin dioxide technology, applied in the direction of material resistance, material analysis, material analysis through electromagnetic means, etc., can solve problems such as poor anti-interference ability, low sensitivity, and easy cracking of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

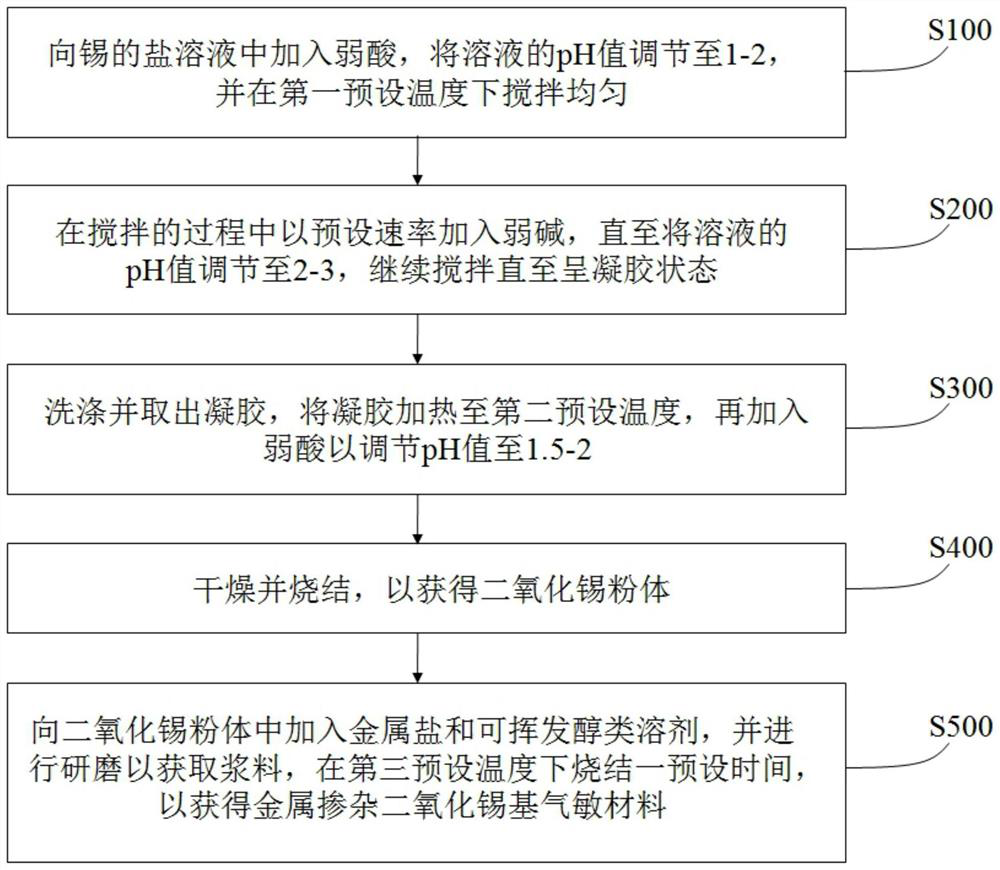

[0037] figure 1 A schematic flowchart of a method for preparing a tin dioxide-based gas sensitive material according to an embodiment of the present invention is shown. Such as figure 1 As shown, the preparation method includes the following steps:

[0038] S100. Add a weak acid to the tin salt solution, adjust the pH of the solution to 1-2, and stir evenly at the first preset temperature;

[0039] S200. Add a weak base at a preset rate during the stirring process until the pH of the solution is adjusted to 2-3, and continue stirring until it is in a gel state;

[0040] S300, washing and taking out the gel, heating the gel to a second preset temperature, and then adding a weak acid to adjust the pH to 1.5-2;

[0041] S400, drying and sintering to obtain tin dioxide powder;

[0042] S500, adding metal salt and volatile alcohol solvent to tin dioxide powder, and grinding to obtain slurry, and sintering at a third preset temperature for a preset time to obtain a metal-doped tin dioxide ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com