A Nonlinear Vibration Absorber with a Segmented Linear Rod

A nonlinear vibration absorber, piecewise linear technology, applied in spring/shock absorber, vibration suppression adjustment, flywheel, etc., can solve the problems of inability to adjust structural parameters, large vibration suppression frequency range, and narrow vibration suppression frequency band. Vibration suppression effect is obvious, vibration suppression frequency bandwidth, strong application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

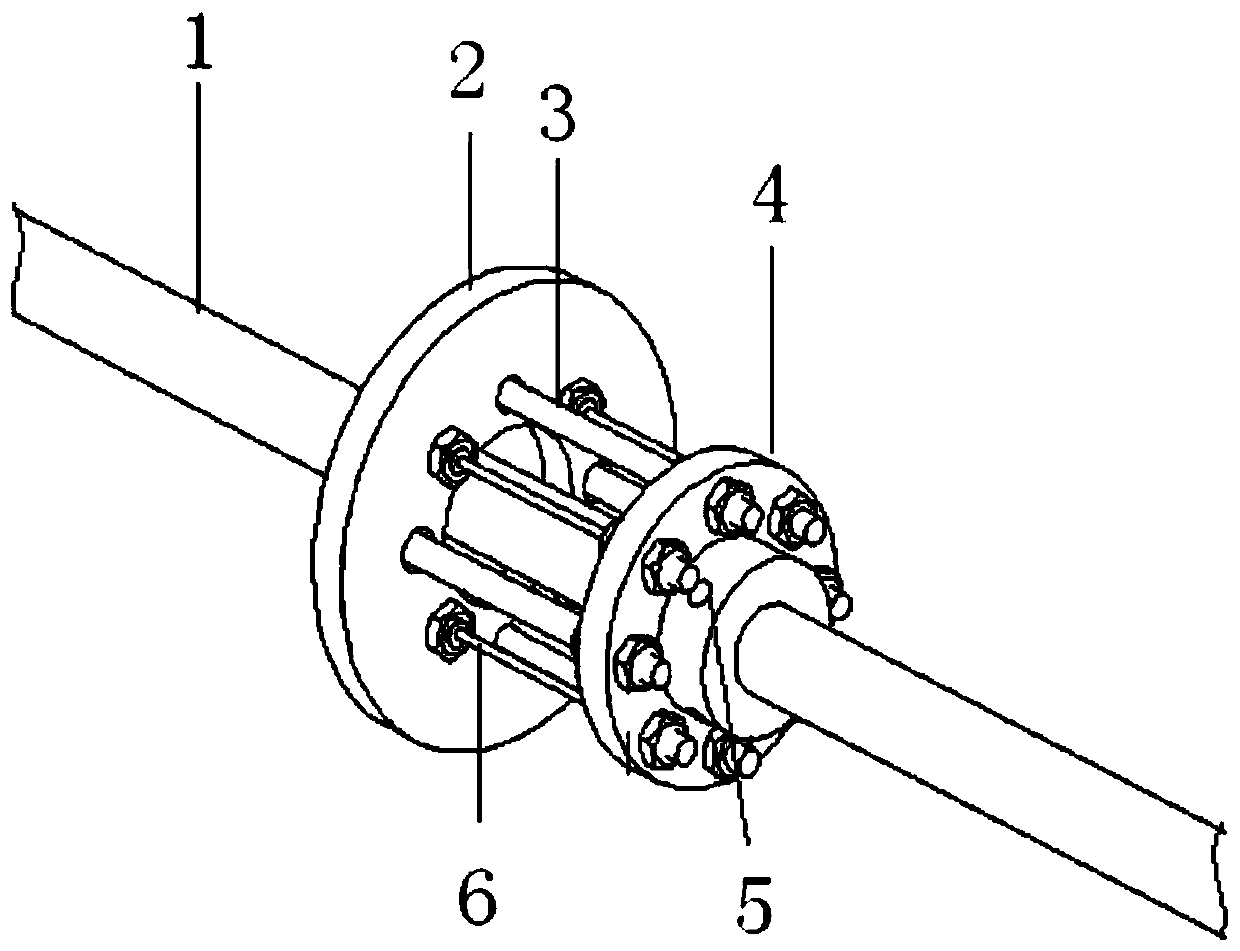

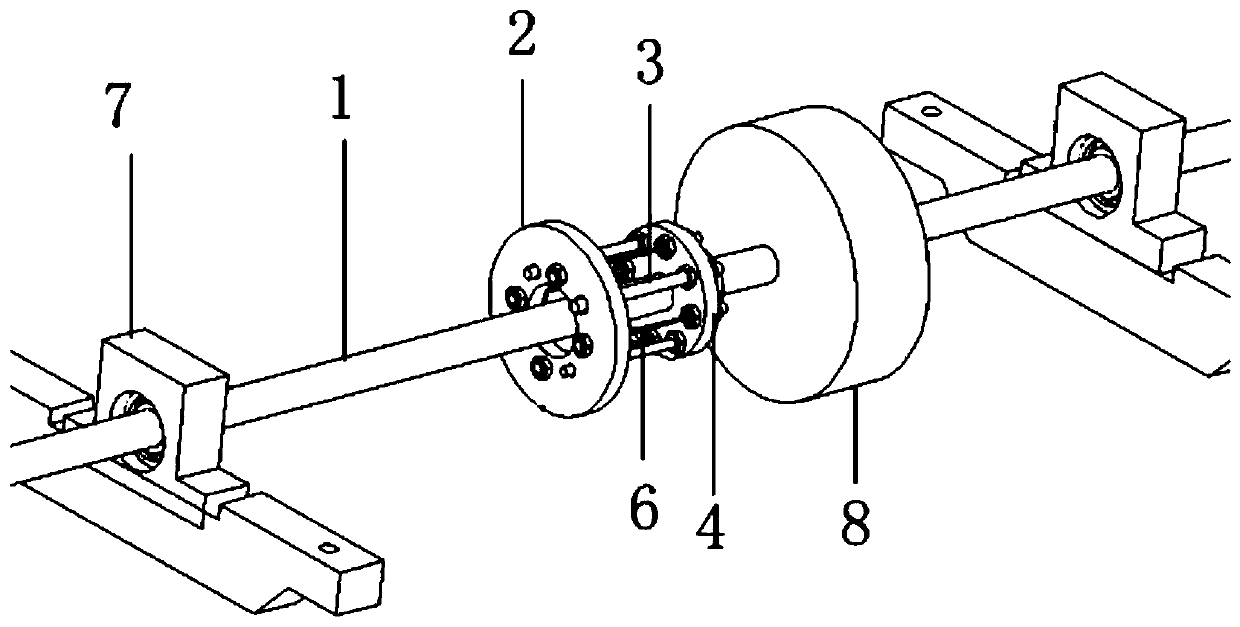

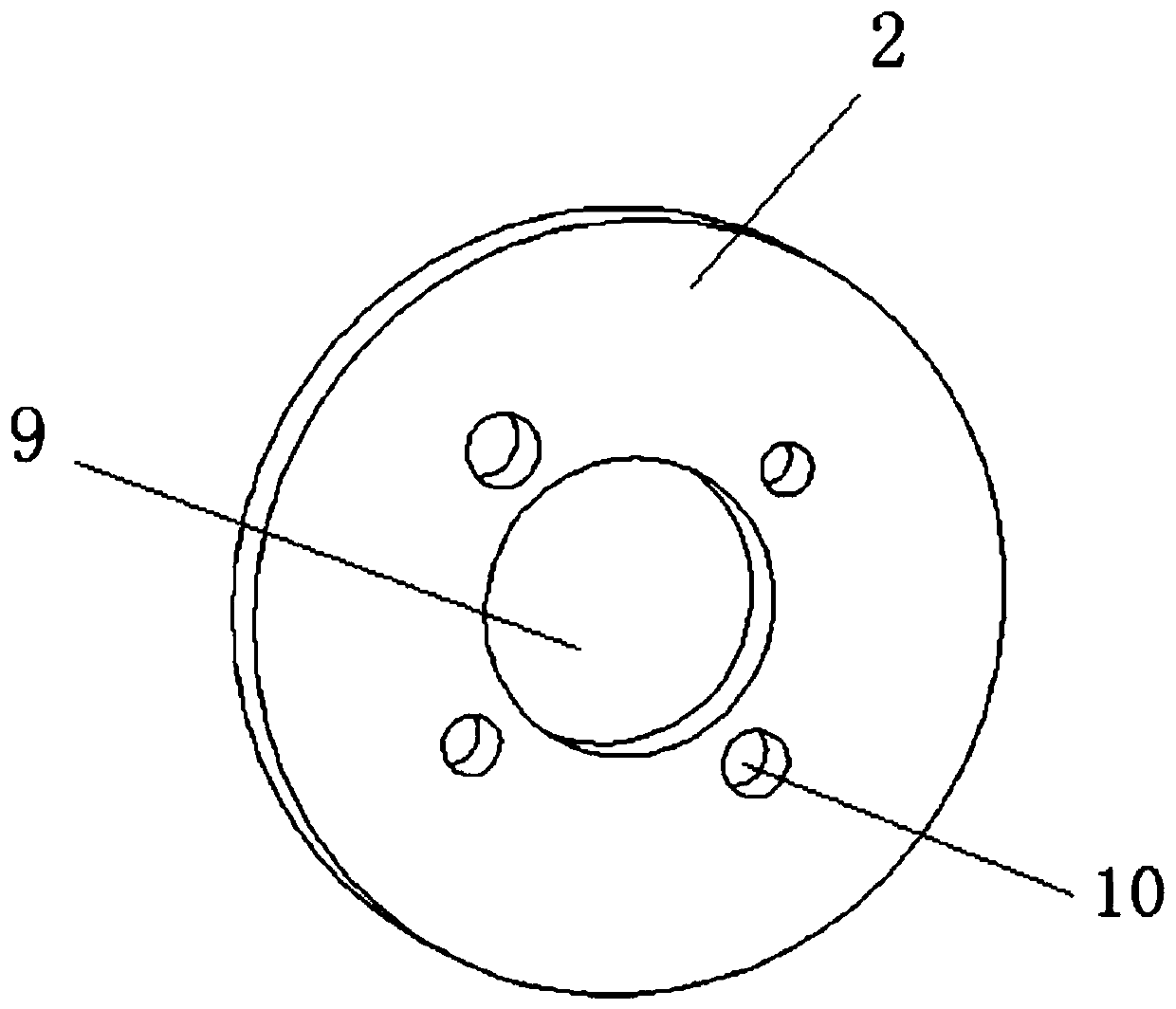

[0020] Such as Figure 1-3 As shown, a nonlinear vibration absorber with a segmented linear rod includes a bushing 4, a fastening screw 5, a connecting rod 6, a segmented linear rod 3 and a mass block 2, and the bushing 4 is arranged between the disc 8 and between the mass blocks 2, and the axial position along the rotor 1 is adjustable; the sleeve 4 is fixedly connected to the rotor 1 through the fastening screw 5, and rotates with the rotor 1; the mass block 2 is a disc structure , the mass block 2 is provided with a central hole 9 and four circular holes 10 with different diameters in a uniform circumferential distribution, and the diameters of the four circular holes 10 are respectively 5mm, 4.5mm, 4mm and 3.5mm; the mass block 2 is set on the rotor 1, the mass block 2 is fixedly connected with the bushing 4 through the connecting rod 6; the segmented linear rod 3 is four rigid rods with different diameters, and the segmented linear rod 3 One end of one end is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com