Combined plastic-wood co-extruded wall plate

A combined, plastic-wood technology, applied in building components, buildings, building structures, etc., can solve problems such as running counter to each other, and achieve the effects of protecting the environment, eliminating the use of adhesives, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

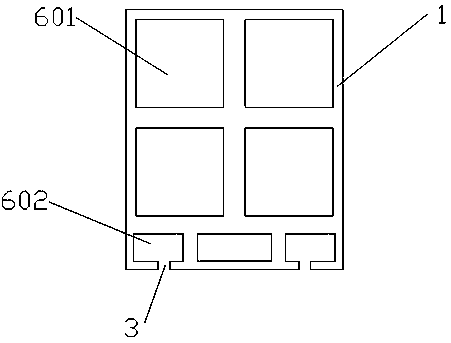

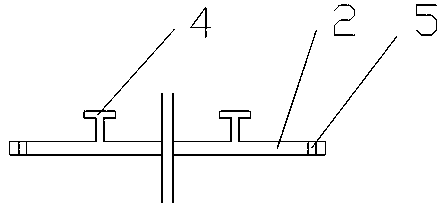

[0016] like Figure 1~2 A combined plastic-wood co-extruded wallboard shown includes a board body 1 and a connector 2, the board body 1 has several cavities, and the two cavities on one side of the board body 1 have channels 3; the connection Part 2 is a flat plate with two T-shaped protrusions 4, and the outside of each protrusion 4 on the flat plate is provided with a fixing hole 5. The width of the longitudinal side of the protrusion is smaller than the width of the channel, and the length of the lateral side of the protrusion is longer than the width of the channel. The board body and the connecting piece are connected through the protrusion snap-in channel, and after the connecting piece is engaged with the board body, the fixing holes on both sides of the connecting piece are located outside the side surface of the board body.

Embodiment 2

[0018] With reference to Example 1, there are four No. 1 cavities 601 with the same cross-section inside the plate body, and the No. 1 cavities are arranged in parallel in pairs. One side of the No. 1 cavity is provided with a number of No. 2 cavities 602. The No. 2 cavity is provided with a channel, and the number of the No. 2 cavity is 3-4.

Embodiment 3

[0020] Referring to Example 2, the protrusion of the connector is snapped into the channel of the plate body, the longitudinal side of the protrusion coincides with the channel, and the horizontal side of the protrusion is snapped into the second cavity corresponding to the channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com