Single-shaft material taking and feeding manipulator

A manipulator and feeding technology, applied in the directions of manipulators, conveyor objects, chucks, etc., can solve the problems of inaccurate picking of small or thin parts, complex structure, and high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

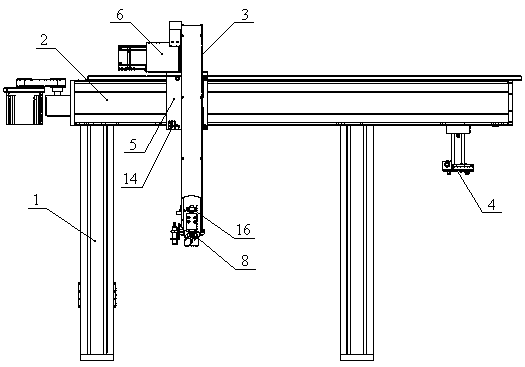

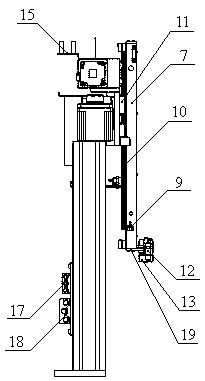

[0015] In the figure: 1. Column, 2. Synchronous belt linear feeding module, 3. Vertical reclaiming module, 4. Air blowing device, 5. Module connection plate, 6. Lifting motor, 7. Module main support, 8. Reclaiming module, 9. Sensor, 10. Guide rail, 11. Slider, 12. Proximity switch I, 13. Electromagnet, 14. Lower limit detection block, 15. Drag chain support plate in left and right directions, 16. Fine adjustment device , 17. Two-position manifold valve, 18. Four-position manifold valve, 19. The lower plate of the main bracket of the module.

[0016] like Figure 1-2 As shown, it includes a column, a synchronous belt linear feeding module, a vertical reclaiming module and an air blowing device;

[0017] The synchronous belt linear feeding module is horizontally fixed on the column, the synchronous belt linear feeding module is provided with a module connecting plate, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com