Solar cell turnover device

A technology of solar cells and flipping devices, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of too many conveying components and large rotation space of the flipping components, so as to realize flipping, reduce the rotation space, and strengthen the leverage The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

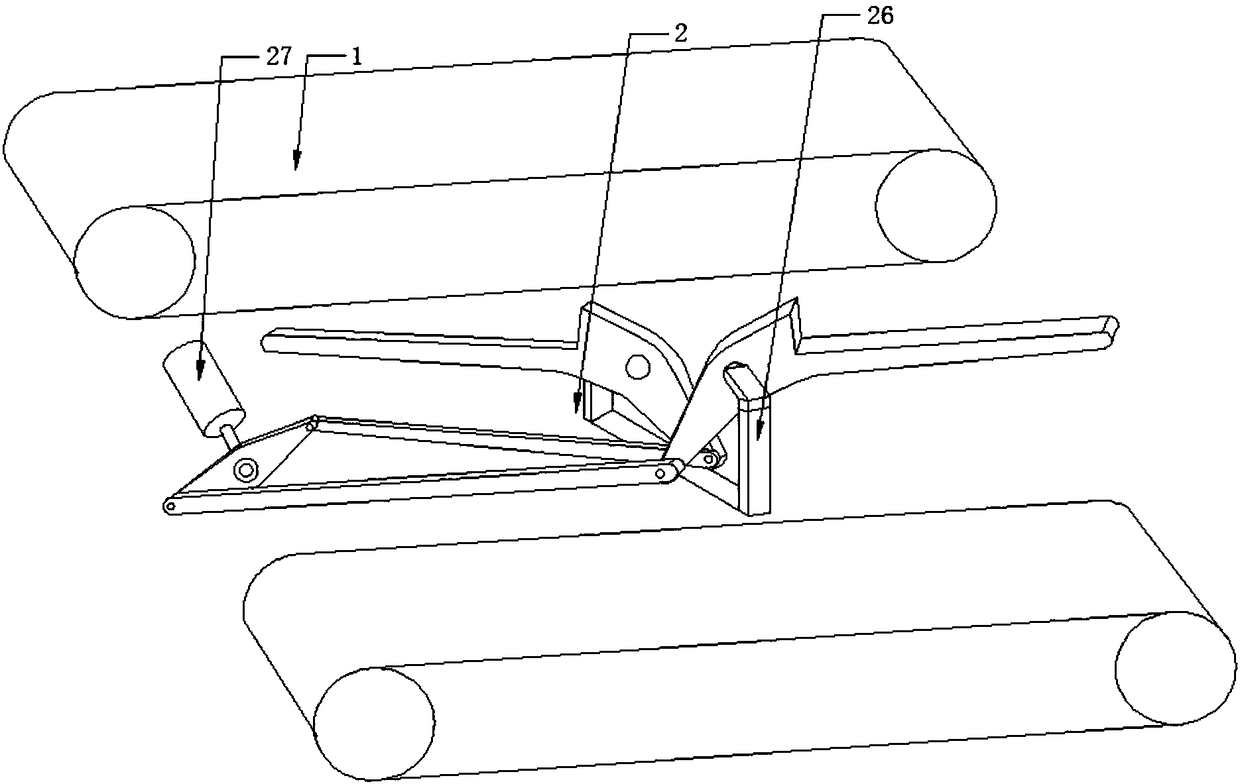

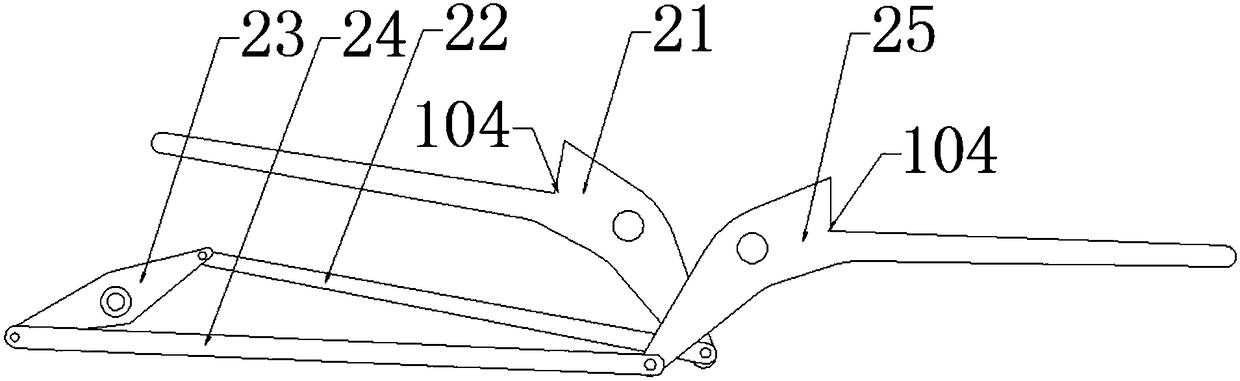

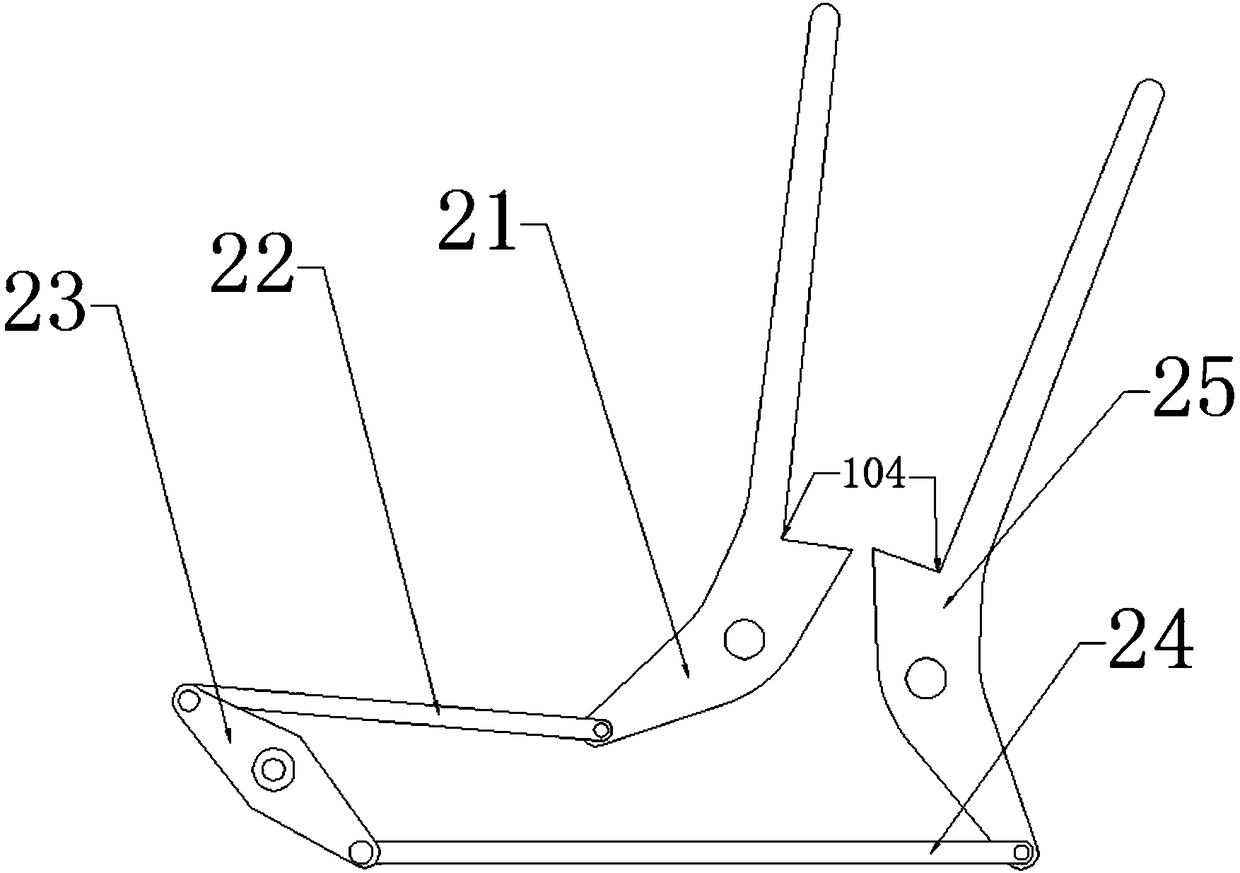

[0035] A solar cell flipping device, comprising two sets of conveying components arranged in parallel and a flipping component arranged on the two sets of conveying components, the solar cells are placed on the two sets of conveying components and hollowed out in the middle, the flipping direction of the flipping mechanism is consistent with the conveying The direction of component delivery is the same. The flipping component includes a bracket, a first support frame, a second support frame and a rotating piece. The center of the rotating piece is hinged on the bracket, and the rotating piece can rotate around the hinge point; the rotating piece The first connecting rod and the second connecting rod are respectively hinged at both ends of the two ends, and meanwhile, the first connecting rod and the second connecting rod are respectively arranged on the two sides of the rotating piece; the other end of the first connecting rod is connected with the first supporting frame Hinged...

Embodiment 2

[0038] On the basis of Embodiment 1, the first support frame includes a rotating block and a support rod, the rotating block includes a first arc surface, one end of the first arc surface is connected to an upper plane, and the other end of the upper plane is connected to a second arc surface, the orientation of the second arc surface is the same as that of the first arc surface, and the other end of the second arc surface is connected to the other end of the first arc surface; one end of the support rod is connected to the upper plane, and the rotating block is The center of gravity of the rotating block is hinged with the support. By connecting two curved surfaces facing the same direction, the rotating block has a certain inclination angle when connecting the support rod, which reduces the length required for the first connecting rod and makes the overall coordination better; in addition, setting the rotating block The hinged position with the bracket is close to the hinge ...

Embodiment 3

[0040] On the basis of the second embodiment, a groove is formed at the connection between the upper plane of the rotating block and the support rod, and the solar cell to be flipped is locked through the groove, and the solar cell is leaned against during the flipping process. On the upper plane of the support rod and the rotating block, so as to realize its flipping function smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com