Anti-collision sleeve of chemical material barrel

A technology of anti-collision sleeves and barrels, which is applied in the field of anti-collision sleeves, can solve the problems of no anti-shock, etc., and achieve the effects of low cost, buffering impact, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

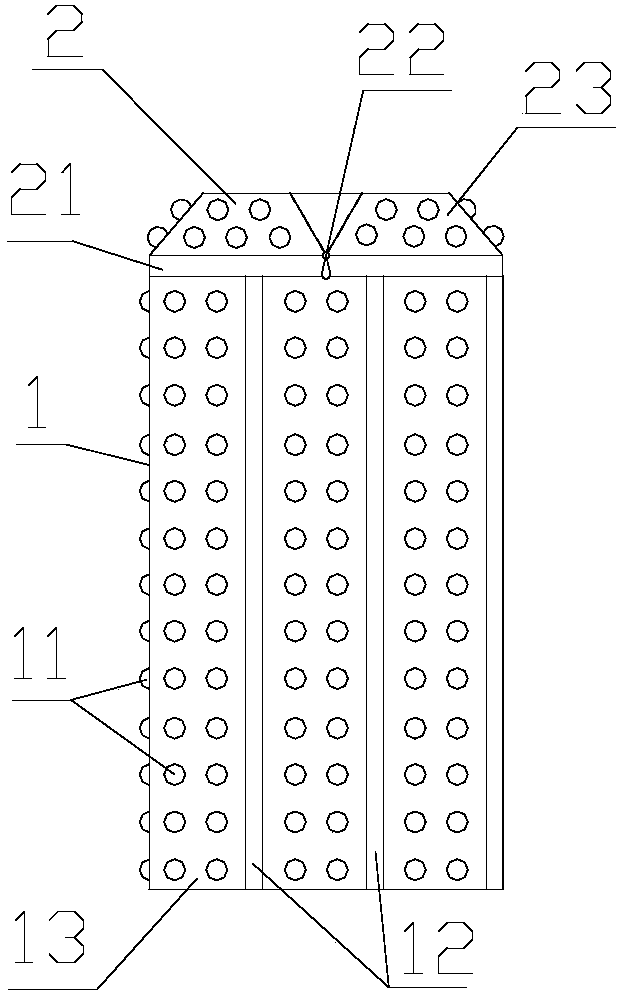

[0015] Such as figure 1 As shown, this embodiment provides a kind of anti-collision cover for chemical tanks, which includes a cover body 1 and a tightening part 2; Tight belt 12, and the circular rubber ring on the bottom surface, each of the rubber belts is provided with 1 to 5 air bags 11, and the circular rubber ring is also provided with air bags; Longitudinal tightening belts are arranged at intervals, which can make the anti-collision sleeve of the present invention adapt to more chemical barrels;

[0016] The tightening part 2 is in the shape of a truncated cone, and includes a contraction ring 23 whose lower edge is connected to the upper edge of the cover body 1, an air bag arranged outside the contraction ring, and a chemical material arranged on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com